Industry

Oil & Gas

For over 20 years, we have helped the oil and gas sector achieve its goals with our asset integrity management solutions. As a result of our ongoing collaboration with Shell, one of the world’s largest oil and gas operators, we know exactly how to support you in making your plant safer and more efficient.

Learn More

Industry

Chemicals

The production of chemical commodities is central to the world’s economy and the demand for chemicals has been growing for years. In 2020 the global sales of chemicals amounted to €3.471 billion. But, as demand increases, so does the strain on the usability of assets. That makes asset reliability management software essential.

Learn More

Industry

Renewable Energy

The oil & gas asset integrity methodologies are easily transferrable to the renewable energy sector. Let us draw on our extensive experience in oil & gas to support you in making your renewable energy operations safer and more efficient.

Learn More

Industry

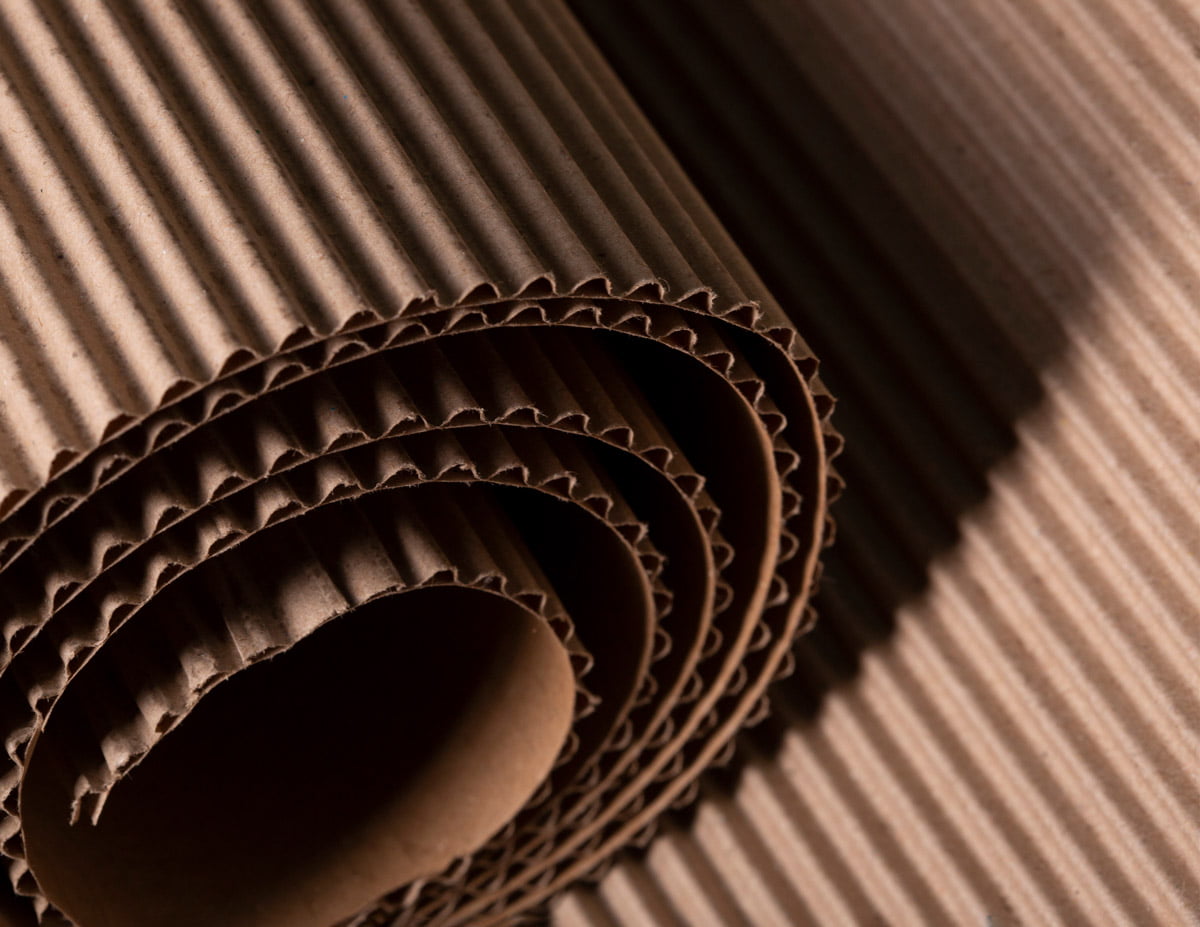

Pulp & Paper

Pulp and paper mills are under increased pressure to remain profitable. Costs associated with energy, process chemicals, and lumber are rising and the competition is high. So what if you could have better uptime, efficiency, and profitability while spending less money on maintenance? It is possible. Let us draw on our extensive experience in oil and gas to support you in making your pulp and paper operations more efficient.

Learn More