Minimal Wall Thickness (Tmin) of a component is a key parameter for ensuring the safe and reliable operation of your critical components such as piping, tanks, and pressure vessels. The calculated Tmin value of an equipment defines the minimum required wall thickness that can safely withstand design pressure and mechanical loads without risk of failure. It is often interchangeably referred to as renewal thickness in our IMS. It is important to note that the renewal thickness excludes the corrosion allowance. By determining Tmin accurately, engineers ensure that the equipment always operates within the design limits established by standards and codes.

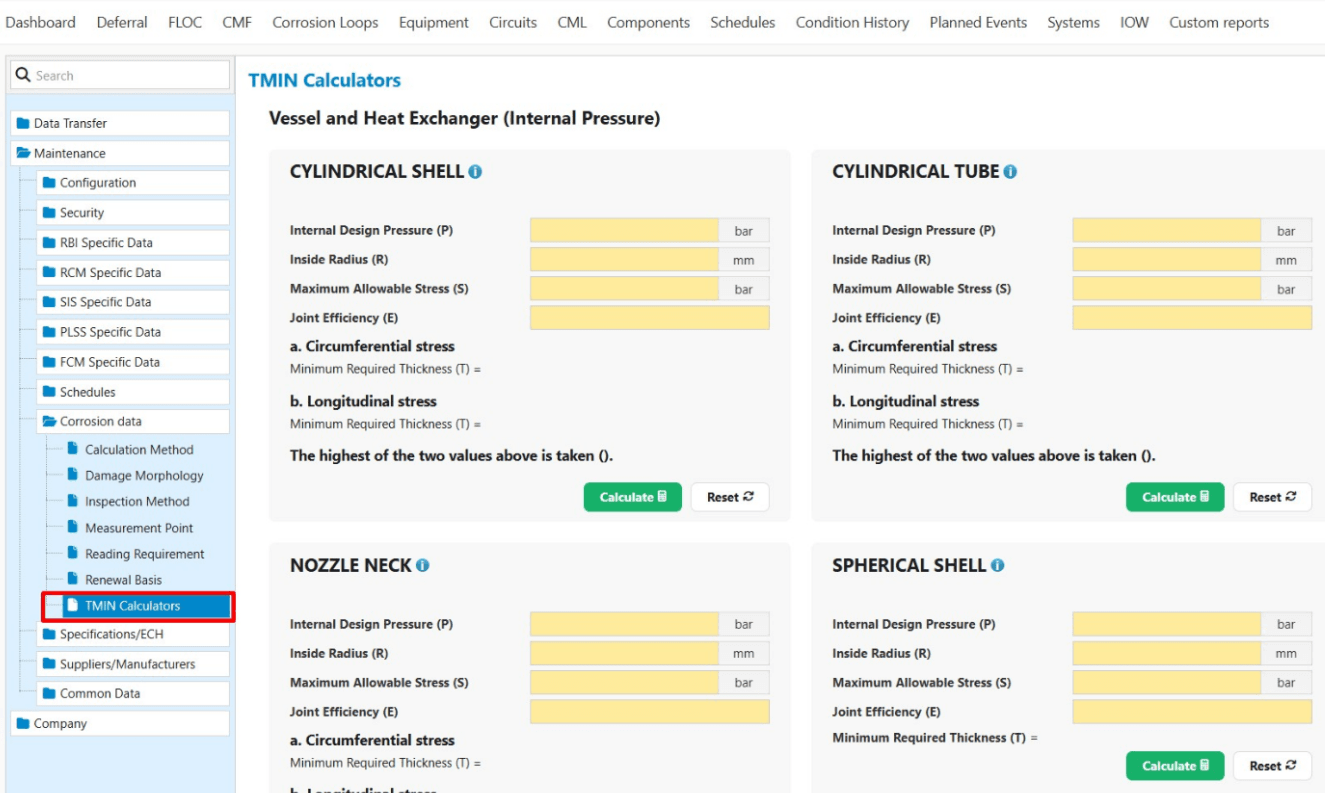

With the latest IMS release, you can use our built-in calculators that can populate the Tmin values in your corrosion monitoring location (CMLs). The Tmin calculators are designed to simplify and standardize these critical calculations across a wide variety of equipment.

As of the current IMS release, IMS provides Tmin calculators for vessels & heat exchangers (cylindrical shell, spherical shell, cylindrical tubes, ellipsoidal heads, torispherical heads, hemispherical heads, nozzle necks), as well as piping (straight piping, bends or elbows, intrados, extrados). Our calculators align with the widely adopted ASME VIII (for vessels and heat exchangers) and ASME B31.3 (for piping), helping ensure compliance and reliability in critical operations.

Applying Minimal Wall Thickness Tmin Calculations in IMS

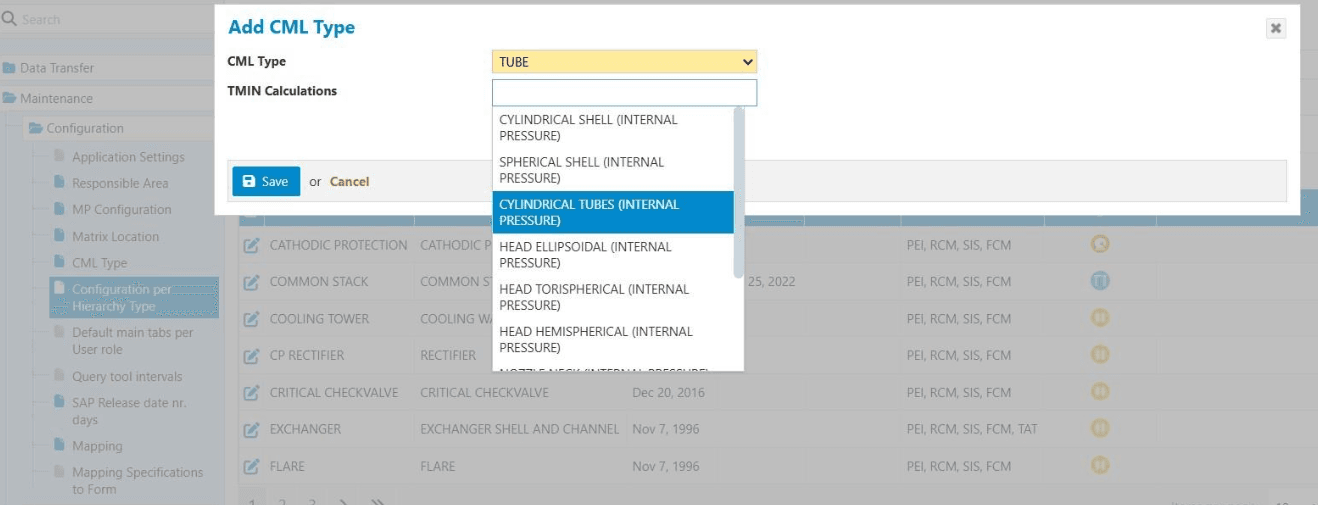

Let us learn how the workflow goes in IMS! It is in the Corrosion Monitoring Locations (CMLs) where renewal thickness values are defined and Tmin calculators are applied. Each CML type and equipment group is mapped to the correct Tmin calculator, ensuring that there are no errors. For instance, a CML on straight piping will automatically trigger the correct Tmin calculator for that geometry. It has been made possible within IMS by a configuration layer which can be managed by the CSA (Corporate Systems Administrator) and INSP ADMIN roles of your organisation. To make the workflow even more effective, the whitelisted CML types for each equipment group determine what calculators are available. This means that you and your fellow engineering colleagues will have consistent and error free Tmin values every single time.

Starting from IMS 4.7 release, the Tmin calculators leverage equipment specifications already stored within the system. This ensures ease of use, and it reinforces data integrity, as the engineers can rely on pre-existing, verified data when performing the renewal thickness calculations.

The Future Expansion of Minimal Wall Thickness Tmin Calculations in IMS

This is not all of it – our Product and Engineering teams have bigger plans to cover more use cases and expand the scope of Tmin calculations. You will soon be able to do structural minimum thickness lookups and material lookups for Tmin calculations. On our roadmap, we also share our plans to support API 530 – Furnaces, API 650 – Tanks, and ASME B31.1 – Power piping in the future.

See the Calculators in Action

Would you like to see the Tmin Calculators in your IMS? Upgrade your IMS to the latest release. You can learn more about the Tmin Calculations functionality in our IMS Handbook. Discover what else is new in our Release notes.

Solicitar una demostración

Do you want your Asset Integrity Management solution to manage these calculations, without the need for another software or plug-in? Fill out the form below and we’ll get in touch to get you started.

Sangeeth Sagar Product Marketing Manager

Sangeeth es ingeniero mecánico y trabajó en los sectores aeroespacial y del automóvil como ingeniero de I+D y pruebas de NVH antes de pasar a la gestión de productos de instrumentación de control de procesos. Forma parte del equipo de gestión de productos y marketing de Cenosco, donde supervisa la estrategia de productos y la gestión de la cartera.