In the heart of every refinery and LNG plant, thousands of gauges, valves, and pipes hold the key to operational continuity. Traditionally, capturing their data required a human presence, inspectors navigating hazardous environments, often climbing scaffolds with clipboards and inspection checklists in hand. But manual data entry is more than just a tedious task; it is a source of delay, human error, and enterprise risk.

As the energy industry moves toward a more autonomous future, the question is no longer just how to collect data, but how to turn that data into immediate, actionable intelligence. This is the core of the strategic partnership between Cenosco and Technip Energies (T. EN), delivering that intelligence with robotic-AIM integration.

Robotics Meets Asset Integrity

The pilot breakthrough unfolded through close collaboration. The objective was ambitious: build a seamless, real-time bridge between Technip’s Cyxense Commander robotic platform and Cenosco’s IMS (Integrity Management System) suite.

This mission was a historic milestone for both companies: it marked the first time Technip Energies successfully interfaced its robotics with existing asset integrity software, and the first time Cenosco’s IMS received live data from a robot.

The pilot transformed the traditional “operating round.” Imagine a robot at a major refinery, originally sent to perform a simple task: read a pressure gauge. In this new integrated workflow, the robot does much more. As it moves through the plant, the robot “scans” its surroundings, capturing high-frequency imagery and critical metadata, including camera orientation and field of view.

The Magic in the Cloud: From 2D Images to 3D Insights

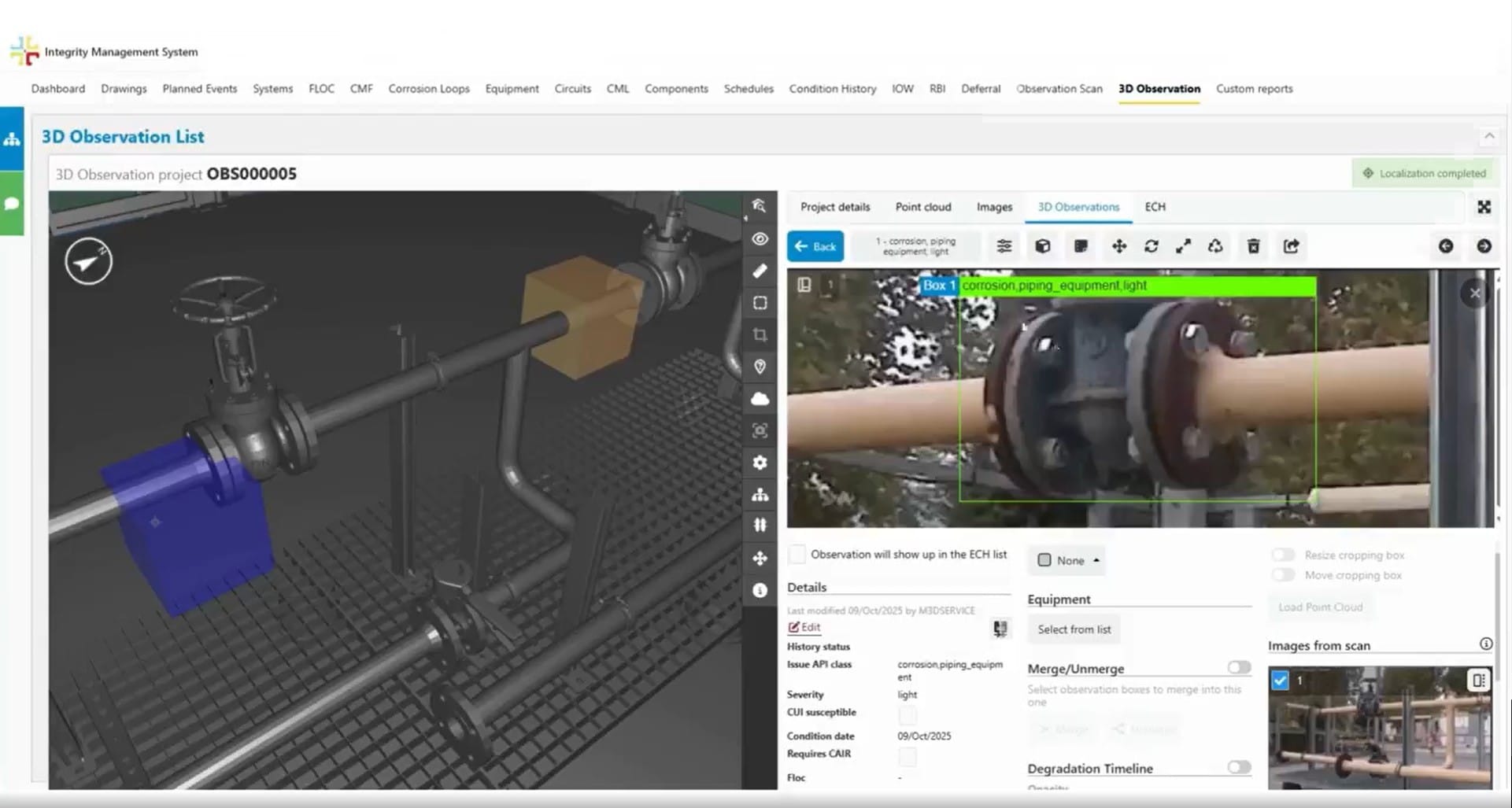

This is where the technology shifts from “cool gadgetry” to “critical infrastructure.” The data captured in the field is uploaded to secure cloud storage instantly. IMS then picks up these 2D images and, using the embedded metadata, superimposes them onto the plant’s 3D Digital Twin.

This creates a “live” visual history of the asset. Whether through advanced AI algorithms or expert human review, issues like pipe cracks, corrosion, or insulation damage are identified and annotated directly on the image.

Because the 3D model is mapped to the IMS database, the system knows exactly which equipment is affected and generates an Equipment Condition History (ECH), a permanent, auditable record of inspection results, maintenance activities, and findings across the asset’s lifecycle. This triggers a Corrective Action Inspection Request (CAIR) that flows seamlessly into SAP or the facility’s CMMS.

This integration even assists with planning: by seeing the issue in 3D, teams can immediately determine if scaffolding is required (e.g., if a repair is 3 meters high) before ever leaving the office. The entire process happens remotely. Which means that no permits, no human field presence, and no manual file exchanges are required. It’s a seamless real-time interaction.

A Multi-Layered Value Proposition

This integration delivers value across the organization: Robotics improves how data is collected, while IMS improves how decisions are made, empowering teams at every level to drive safer, smarter operations, ultimately protecting production and margins.

- Robotics removes people from hazardous environments, eliminating exposure to trip and slip hazards. Higher-quality, more consistent data comes from repeatable inspections that improve defect detection and trending. Less manual work means data is automatically structured and linked to equipment, degradation mechanisms, and equipment condition history. Engineers spend less time chasing data and more time assessing risk and defining mitigation: better data in, clearer decisions out, with less effort and lower risk.

- Better inspection prioritization increases coverage and frequency, with risk-ranked findings so teams focus on what matters. Faster, better decisions flow directly from inspection data into assessments, planning, and execution, reducing delays between “finding” and “action.” Improved cross-discipline alignment provides one shared integrity view across inspection, corrosion, maintenance, and operations instead of siloed tools and spreadsheets. More efficient use of people means less time organizing inspections and consolidating data, more time managing risk and performance: fewer surprises, better planning, and tighter control of integrity risk.

- Protection of production and margins enabled by more frequent, higher-quality inspections without shutdowns. Integrity risks can be identified earlier and managed proactively to reduce unplanned downtime. Lower enterprise risk and stronger license to operate come from digital inspection records, traceability, and risk-based decisions that improve auditability and regulatory confidence across the assets. Capex and lifecycle optimization through earlier detection and better-targeted maintenance extends asset life and avoids premature replacement. Credible digital transformation demonstrates leadership in pragmatic digitalization, which is focused on outcomes, not technology for its own sake: Robotics powered by IMS protects revenue today and asset value tomorrow.

The New Standard: Better Data In, Clearer Decisions Out

The true impact of this partnership lies in the fundamental transformation of daily operations. While a robot’s primary mission may be a routine check of a gauge reading, the breakthrough is the “incidental” inspection it performs simultaneously. By scanning the surroundings while navigating the deck, the robot captures a constant visual truth of the site, turning every round into an integrity-building mission.

From a practical standpoint, this allows an operator to manage the facility’s health entirely from the safety of an office or trailer. By eliminating manual file exchanges and human field presence, the system removes the need for work permits and traditional logistics for basic checks. Much like drone technology has drastically reduced costs in the energy sector, this robotic-AIM integration brings that same level of massive cost-efficiency and safety to the ground level, providing a seamless, automated loop between the field and the office.

The partnership between Cenosco and Technip Energies marks a first for both companies: a seamless loop where robotics improves how data is collected, and IMS improves how decisions are made. We are not just automating inspections; we are building a safer, more predictable future for the global energy infrastructure.

Solicite una demostración

Are you ready to see the Cenosco & Technip Live Robotic-AIM Integration live? Fill out the form below to book a demo!

Denis Tkalec Technical Writer

Denis Tkalec is a technical writer at Cenosco, specializing in asset integrity management software since 2022. With a background in education and six years in marketing, she turns complex topics into clear, user-friendly content. Inspired by Camus’s belief that “a writer keeps civilization from destroying itself,” she brings precision and care to every manual.