In demanding industrial environments such as oil and gas plants, the chemical industry, and mining, corrosion poses a constant threat to equipment integrity, worker safety, and environmental protection. Timely detection and accurate assessment of corrosion are key to preventing costly failures, unplanned shutdowns, and potential environmental incidents.

Cenosco, a leading company in the development of Asset Integrity Management (AIM) software, recognized the need for innovative solutions to enhance existing inspection and monitoring methods. Although conventional approaches remain reliable, they can be time-consuming and susceptible to human bias, while the growing volume of visual data generated during inspections adds to the challenge.

The Solution Through the Test-Before-Invest (TBI) Program

To explore the potential of emerging technologies, Cenosco partnered with the EDIH Adria consortium through the “Test Before Invest” (TBI) program. The objective of this collaborative project was to develop and test a prototype artificial intelligence (AI) model capable of automatically identifying, classifying, and assessing the degree of corrosion based on photographs of pipelines and other components of industrial assets.

The focus was on applying advanced computer vision and deep learning techniques to automate and render the analysis of visual inspection data more objective.

As part of the TBI activities, experts from the Juraj Dobrila University of Pula, a partner within the EDIH Adria consortium, worked with an extensive dataset provided by Cenosco. Key steps included:

- Detailed data analysis and preparation: The initial dataset consisted of high-resolution photographs and their corresponding annotations. The data underwent cleaning and validation to ensure consistency throughout.

- Developing a strategy for processing high-resolution images: Since standard image scaling for AI models can lead to loss of detail, an innovative technique was implemented to divide the original images into smaller, overlapping segments. This approach proved essential for preserving the fine detail necessary for accurate corrosion detection.

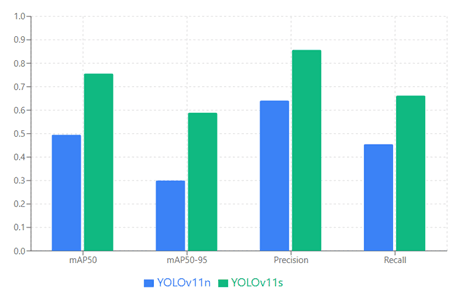

- Training and evaluating AI models: The YOLOv11 (You Only Look Once) architecture was employed, known for its efficiency in object detection tasks. Both “nano” and “small” model variants were tested, with the “small” model exhibiting superior performance after 38 hours of training.

Figure 1 – Comparison of YOLOv11 model performance

Figure 2 – Example of damage detection

Results and Benefits for Cenosco

The TBI project successfully demonstrated the technical feasibility and significant potential of applying AI for automated corrosion detection:

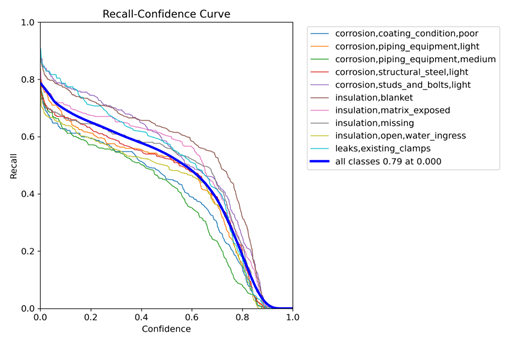

- Satisfactory performance achieved: The YOLOv11 small model reached a mAP50 value of 0.756 and mAP50-95 of 0.589 on the validation set, both promising results for a complex industrial task. The model achieved a precision of 0.857 and a recall of 0.662. Upon deeper class-level examination, corrosion on coatings was detected with the highest accuracy, whereas spotting moderate corrosion on pipeline equipment and insulation faults proved more challenging. With a recall of 0.79 at a confidence threshold of 0.000, the model has proven its consistent capability to accurately identify diverse defect types in industrial environments.

Figure 3 – Recall-Confidence curve of YOLOv11 model by classes

- Confirmation of the “tiling” strategy’s effectiveness: Dividing images into smaller segments allowed the model to learn effectively from fine details, which proved crucial for detecting subtle signs of corrosion.

- Insight into automation potential: The AI model demonstrated the ability to quickly analyze large volumes of images, identifying corrosion-affected areas and classifying their type and severity. This paves the way for significant time savings compared to manual review and improves consistency of assessments.

- Foundation for future development: Through the project, Cenosco gained detailed insights into the applicability of AI technology for corrosion detection, including a demonstration of the prototype’s functionality, performance evaluation, and a comprehensive report with recommendations. These findings provide a solid foundation for Cenosco’s future decisions on further refining and potentially integrating advanced AI features into its Integrity Management Suite (IMS). The project successfully demonstrated technological feasibility at TRL levels 3–4.

Lessons Learned and Next Steps

This TBI project provided Cenosco with valuable insights:

- The importance of high-quality data: The success of AI models fundamentally depends on large, diverse, and accurately annotated datasets.

- Adapting to specific challenges: Standard approaches often require innovative adjustments, such as the image-splitting strategy, to address the specifics of industrial data.

- Iterative development: AI solutions require continuous improvement, experimentation with new architectures and techniques, and adaptation based on feedback.

Cenosco plans to continue its research and development of AI solutions, focusing on further improving model accuracy and expanding the dataset. The goal is to provide clients with even more advanced tools for proactive asset integrity management, risk reduction, and maintenance cost optimization.

Conclusion

The collaboration between Cenosco and EDIH Adria through the TBI program has successfully demonstrated how artificial intelligence can transform inspection and maintenance processes in demanding industrial sectors. This project not only confirmed the technical feasibility of AI-based corrosion detection but also laid the groundwork for future innovations that will enhance the safety, efficiency, and sustainability of industrial facilities.

The successful completion of this project highlights the strength of collaboration between Cenosco and EDIH Adria, whose support and expertise were instrumental in advancing digital innovation within the industrial sector.

Prêt pour une démonstration ?

Êtes-vous prêt à voir la suite IMS en action ? Remplissez le formulaire ci-dessous pour réserver une démonstration !