Asset integrity management is built on snapshots, but reality is a live stream. How do we escape the static trap and bridge the gap between periodic inspections and continuous degradation? What if you could leverage an intelligent Asset Integrity Management (AIM) Software solution capable of providing real-time intelligence to anticipate failures before they occur?

IMS manages some of the most complex infrastructure on Earth. From offshore facilities and pipelines to storage tanks, LNG plants, chemical plants, and refineries, our assets are living, breathing, and degrading every second.

Yet when it comes to safeguarding asset integrity, organizations still operate within frameworks shaped by regulatory requirements, operational constraints, and the practical realities of data availability. We use Risk-Based (RBI) software to plan inspections on fixed intervals, following established RBI models, not because the industry is slow to modernize, but because these cycles are essential for compliance, governance, and auditability. We conduct visual rounds to meet mandated observation frequencies. We compile reports to satisfy assurance processes that have kept facilities safe for decades.

These traditional methods remain vital, they are the foundation of modern integrity management. They embody engineering discipline, codified standards, and the lessons of past incidents. But they were built for a world where continuous data streams did not yet exist. As a result, they operate on periodic snapshots, while degradation evolves continuously between inspection cycles.

What is changing now is not the importance of RBI or visual inspection, but the environment around them. Sensors, robotics, and machine learning now make it possible to augment these trusted processes with evidence that updates itself. The opportunity is not to replace regulated, cyclical practices — but to enrich them through an asset integrity management platform that integrates inspection planning software and live sensor data.

At Cenosco, we believe the next leap forward comes from embedding real-time asset intelligence inside the structure of existing integrity programs. That means enabling RBI software to refresh dynamically with live data, allowing degradation assessments to evolve as new evidence appears, and creating a continuous feedback loop that strengthens auditability rather than challenging it. Continuous intelligence becomes a complement to periodic cycles — filling the gaps, reducing uncertainty, and elevating engineers’ ability to make decisions with confidence.

From a C-level executive perspective, the urgency is clear. Integrity teams are highly skilled but chronically stretched — not because they produce “meaningless reports,” but because the current processes create unavoidable inefficiencies: repeated manual data compilation, reactive rather than predictive interventions, and limited ability to prioritize across hundreds of assets. This inefficiency translates into real cost: reduced production and elevated risk exposure to a major black swan event. The upside of real-time intelligence, enhanced by predictive corrosion modeling, is not abstract — it shows up directly in key metrics: reduced unplanned outages, extended asset life, optimized inspection budgets, and materially lower operational risk.

From Periodic Oversight to Continuous Awareness: Real-Time Intelligence

Asset integrity management today happens in cycles. Visual inspections occur quarterly or after shutdowns. But degradation doesn’t wait for our schedules — it evolves continuously.

The next generation of Asset Integrity Management will be driven by a living network of IIoT sensors and autonomous inspection robots — drones, crawlers, and quadrupeds — streaming live data on temperature, vibration, wall thickness, corrosion potential, and emissions. These digital observations become new inputs to existing RBI frameworks. Instead of manually refreshing models, advanced RBI software continuously updates likelihood-of-failure estimates using real-time evidence.

AI agents, trained on historical and physics-based models, interpret these data streams — distinguishing normal behavior from early signs of degradation. Combined with integrity digital twins grounded in real engineering physics, this creates a dynamic understanding of asset health.

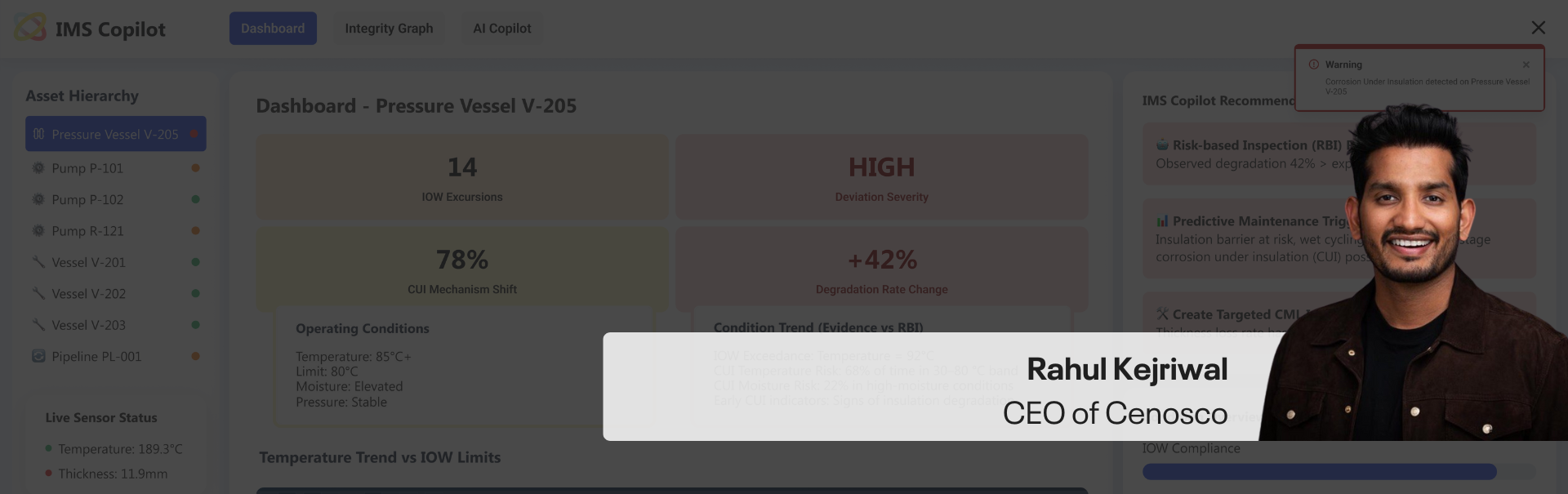

Imagine an RBI dashboard that offers insightful and actionable suggestions as new sensor data arrives. A corrosion loop that receives risk ranking suggestions in real time. A pipeline that identifies its own hotspots before they become leaks. Meanwhile, inspection planning software seamlessly integrates this intelligence, enabling dynamic and prioritized inspection workflows. This is real-time integrity intelligence — where physical inspection is super-charged with continuous digital awareness, yet the trusted methodologies of RBI and visual inspection remain essential reference points.

The Brain: The Integrity Graph

As real-time data begins to pour in from sensors, robots, and inspection systems, the challenge is no longer collecting information — it’s understanding it. In today’s plants, data is abundant but fragmented. Corrosion logs live in spreadsheets. RBI models sit in isolated databases. Sensor readings stream into control systems that rarely talk to the asset integrity management tools.

To turn this noise into intelligence, Cenosco is building what we call the Integrity Graph — a living, interconnected representation of every asset, its condition, and its evolving risks.

Unlike traditional databases, the Integrity Graph will not just store data; it will understand relationships. It will know how a pump’s vibration profile relates to bearing wear, how a temperature excursion affects corrosion rate, and how a small leak could accelerate nearby degradation. It will connect materials, failure modes, operating conditions, and inspection results into a single semantic network — a system that captures not just what is happening, but why.

This graph will become the foundation for real-time reasoning. As IIoT sensors report temperature or thickness changes, as drones capture images of insulation damage, or as engineers log new inspection findings, each data point will update the graph’s understanding of the asset’s state. The models inside it — physics-based and data-driven — will continuously make suggestions to engineers on likelihood-of-failure estimates, risk rankings, and help identify non-obvious patterns across units and plants.

In time, the Integrity Graph will evolve into the collective memory of the organization — a living model of how assets behave, degrade, and respond to intervention. It’s the bridge between observation and insight, between data and action. And it is what makes the next step possible: AI copilots that think in context, make recommendations in real time, and help engineers see not just what’s happening.

The Copilot Architecture: Domain Expertise at Scale

As asset integrity moves into the age of real-time data, the engineer’s role is being redefined — not replaced. The future of Asset Integrity Management isn’t about removing human judgment; it’s about extending it with intelligence that never sleeps.

At the heart of this transformation is what we call the Copilot Architecture, a new class of AI collaborators purpose-built for engineering reasoning. These copilots are not generic assistants or large language models; they are domain-specialized systems trained on decades of inspection data, degradation models, and standards like API 571, API 580, and ISO 14224.

The first such copilot that Cenosco is working on is the Degradation Mechanism Copilot, a digital expert that will not just monitor known damage mechanisms but actively help diagnose which ones are at play. Through advanced predictive corrosion modeling, it continually updates its understanding of damage progression, improving the accuracy of its recommendations.

In the future, when an engineer selects a piece of equipment, such as a heat exchanger shell, the copilot will draw on a combination of factors, including the material of construction, process temperature, pressure, chemical environment, inspection findings, and live sensor readings. From this, it will infer and rank the most probable degradation mechanisms — whether it’s high-temperature sulfidation, chloride-induced stress corrosion cracking, erosion-corrosion, or simple thinning. It will cross-reference these possibilities with known operating histories and environmental conditions, explaining why certain mechanisms are more or less likely.

But it will not stop at identification. The copilot will continuously make suggestions as new data will flow in — from ultrasonic thickness readings, visual inspection images, or surface temperature sensors. If a drone detects hot spots, or an IIoT probe reports rising moisture beneath insulation, the copilot will recalibrate its hypothesis and update it’s recommendation of corrosion under insulation (CUI) or external corrosion accordingly. It will then recommend next steps: which inspection methods would most efficiently confirm the active mechanism, what monitoring adjustments to make, and how to update the RBI model’s likelihood-of-failure. All of this happens transparently — every inference traceable, every assumption explainable, every recommendation grounded in engineering logic and empirical evidence.

Over time, the Degradation Mechanism Copilot will become an institutional expert that learns continuously. It absorbs feedback from human engineers, correlates plant experiences across sites, and builds a richer understanding of how degradation actually evolves in the real world. What emerges is a shared, ever-learning intelligence — one that fuses human judgment, physical models, and data-driven reasoning into a single, trusted partner for every integrity engineer.

The Human in the Loop: Uncompromising Accountability

As integrity decisions become increasingly augmented by AI, another question emerges for senior leadership: who carries responsibility when an AI-supported recommendation influences — or fails to influence — an outcome?

This is like the debates around accountability in autonomous vehicles. In our domain, the answer must remain unequivocal: engineering judgment, regulatory compliance, and operator governance stay firmly in control. AI can surface insights, detect anomalies earlier, and propose optimized interventions, but it does not replace the responsible engineer of record.

For organizations to trust this evolution, every AI-driven suggestion must be explainable, traceable, and auditable — ensuring that the chain of accountability remains intact, and that regulators can see not only what decision was made, but why.

The Destination: Goal Zero as an Operating Model

The future of Asset Integrity Management isn’t about replacing engineers or discarding proven methods. RBI, corrosion models, and visual inspections remain essential; they provide the foundation upon which real-time intelligence is built. What is changing is how these inputs are collected, interpreted, and acted upon.

This transformation is powered by integrity digital twins that create dynamic, physics-based models of assets updated with continuous data from sensors and autonomous inspections. Coupled with AI copilots, such as the Degradation Mechanism Copilot, these tools enable organizations to make integrity decisions faster, more consistently, and with greater confidence.

Over time, these systems capture institutional knowledge and help prioritize interventions based on evidence rather than assumptions. This will help less experienced engineers and managers be more confident and reduce the stress of overburdened engineers and managers struggling to make time to deal with what really matters.

This approach moves organizations closer to Goal Zero, a state where risks are visible before they become incidents, maintenance is informed rather than reactive, and assets are managed proactively based on real-world behavior. Achieving Goal Zero doesn’t mean eliminating all risk; it means making uncertainty manageable, predictable, and transparent.

Cenosco’s AI Plan is designed to make this transition practical and achievable, not as a theoretical ideal, but as a grounded, implementable evolution of asset integrity management. By combining human expertise, trusted engineering methods, and real-time asset intelligence, companies can protect people, processes, and infrastructure while steadily reducing the likelihood of unexpected failures.

Rahul Kejriwal CEO

Rahul Kejriwal, CEO of Cenosco, is a seasoned leader in Enterprise SaaS with 10+ years in tech and finance. He has led teams in engineering software and invested in high-growth tech firms globally.