As oil and gas assets age and budgets tighten, the need for smarter, data-driven inspections has never been greater. At AUTOMA 2025, Cenosco’s Tomislav Renić explored how digital maturity, AI, and dynamic risk models are reshaping traditional approaches to risk-based inspection. Continue reading to discover how connected data ecosystems and predictive analytics are enabling continuous, adaptive, and safer integrity management.

The Current Integrity Challenge

Many assets now operate beyond their original design life, increasing the risk of failures, leaks, and unplanned downtime. Meanwhile, inspection budgets are shrinking, requiring operators to do more with fewer resources—without compromising safety.

Traditional inspection regimes, often based on fixed schedules or prescriptive standards, frequently misallocate effort: over-inspecting low-risk components while under-monitoring high-risk ones. These approaches also struggle to generate actionable insights from the growing volume of data.

Key limitations include:

- Over-inspection of low-risk items.

- Risk assessments based on incomplete or siloed data.

- Limited decision intelligence despite abundant data.

The Digital Maturity Journey

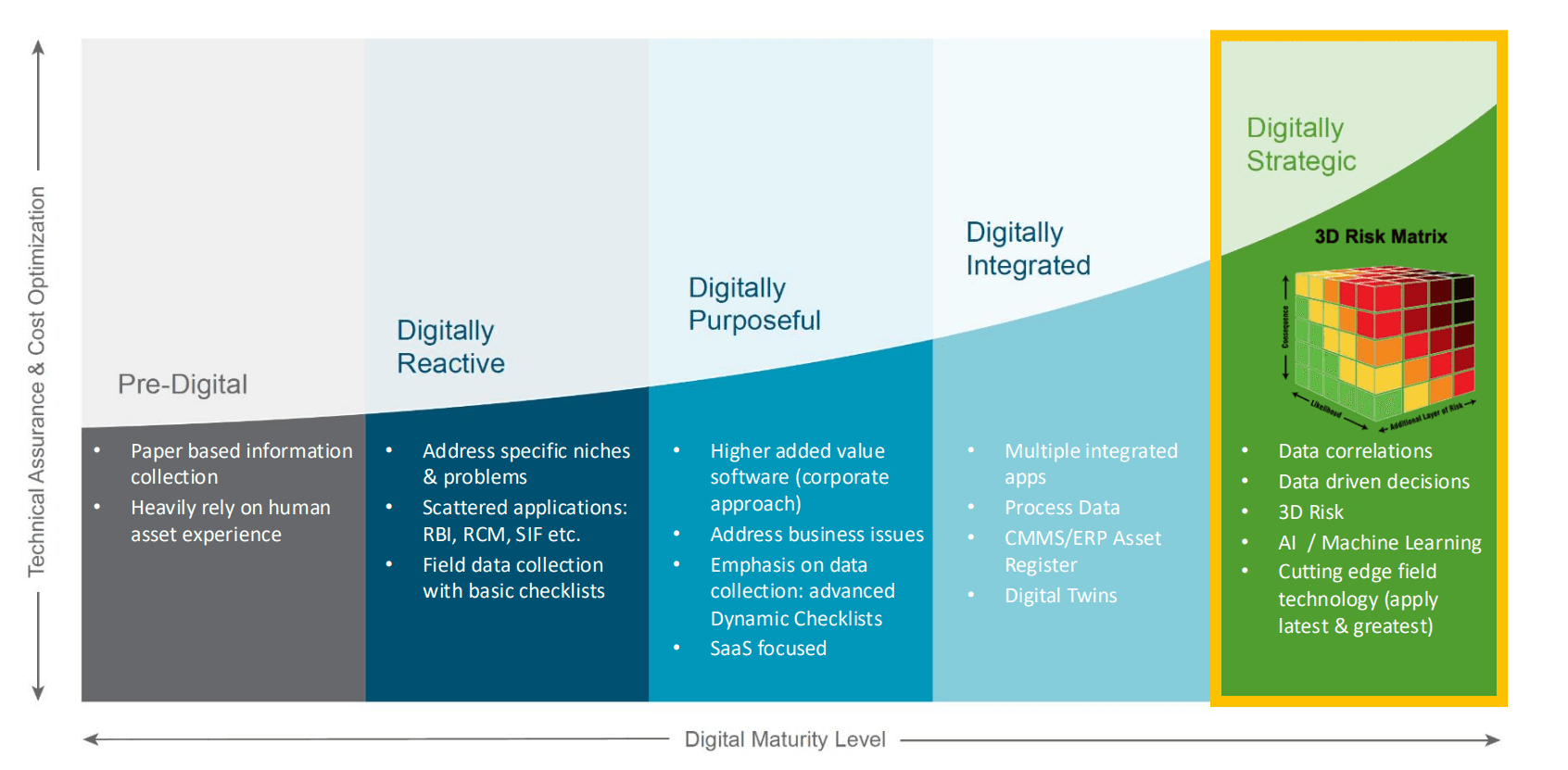

Modernising risk-based inspections begins with assessing an organisation’s digital maturity. Cenosco’s Digital Maturity Framework defines four stages:

- Pre-Digital: Paper-based records; heavy reliance on individual expertise.

- Digitally Reactive: Scattered tools (RBI, RCM); basic digital checklists.

- Digitally Purposeful: Corporate software; advanced data collection; SaaS platforms.

- Digitally Integrated & Strategic: Full integration of process data, CMMS/ERP, digital twins, AI/ML, and 3D risk visualisation.

The goal is to evolve from mere data collection to decision intelligence.

Core Components of a Modern Integrity Ecosystem

- Rich Data Foundation

- Smart sensors, IoT networks, corrosion monitoring, NDT results, and digital field reports unified in a single platform.

- Centralised systems enable descriptive and diagnostic analytics across the entire asset base.

- AI-Driven Transformation

- Supervised machine learning models detect defects and predict failure modes using real-time operating conditions.

- Pattern recognition identifies corrosion trends, thinning rates, and anomaly clusters—moving beyond statistical averages to predictive precision.

- Integrity Operating Windows (IOWs)

- Define safe operating boundaries tied to specific degradation mechanisms (e.g., erosion, stress corrosion cracking).

- Real-time process data triggers automated alerts when limits are exceeded, enabling immediate mitigation.

Moving Beyond Static Risk Models

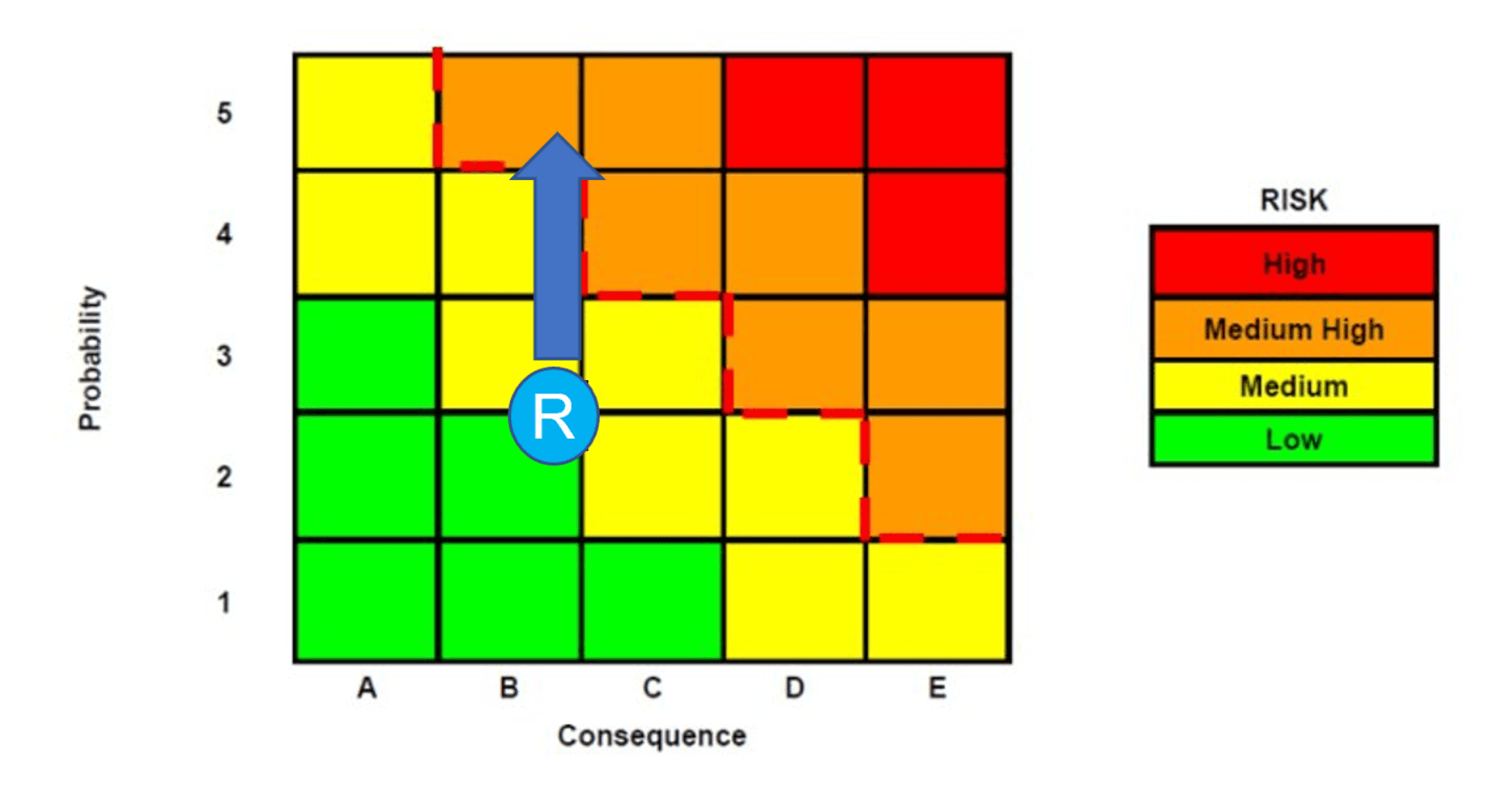

Conventional RBI marked a significant improvement over time-based inspections, enhancing safety, efficiency, and reliability. However, it assumes risk remains static between inspection events—a critical limitation.

Dynamic RBI addresses this through adaptive risk models that continuously integrate live sensor and process data, adjust in response to operational changes and monitoring inputs, and drive condition-based inspection planning, replacing fixed schedules.

By combining digital twins, AI/ML, and pervasive sensor networks, dynamic RBI recalculates the probability of failure (PoF) and consequence of failure (CoF) in near real-time, incorporating both internal changes (e.g., throughput, process modifications) and external factors (e.g., commodity prices).

“Risk models evolve as assets evolve.”

Core Technical Enablers

Recent advancements have made dynamic RBI feasible:

- IoT and Edge Sensing: Affordable, high-frequency monitoring of pressure, wall thickness, temperature, vibration, etc.

- Digital Twins: Virtual replicas simulating current and future operating states.

- AI and Predictive Analytics: Anomaly detection, corrosion forecasting, and continuous risk model refinement.

- Integrated Platforms: Cloud systems automating risk ranking, inspection scheduling, data collection, and real-time model updates.

Feedback and Continuous Learning

The dynamic RBI workflow forms a closed-loop process for continuous optimisation:

- Gather → Sensor and inspection data.

- Analyse → AI compares predicted vs. actual degradation.

- Act → Automated alerts and workflow triggers.

- Learn → Discrepancies refine models across the asset fleet.

The Future Vision

Cenosco supports a unified integrity strategy:

Pillar and the Outcome

- Unified Data Sources: Reliable, connected foundation for all integrity inputs.

- Decision-Ready Insights: Raw data transformed into proactive, dynamic risk profiles.

- Smarter Asset Management: Shift from reactive to intelligent, continuous, and adaptive strategies.

Predictive automation and digital integration enable condition-based integrity management – reducing surprises, optimising resources, and strengthening safety.

The Bottom Line

Digital transformation is no longer optional. The future of asset integrity depends on connected data ecosystems, AI-driven predictions, and dynamic risk models. As ageing infrastructure and cost pressures mount, success hinges on automation, integration, and intelligence—turning data streams into precise, preemptive action.

Pronto para uma demonstração?

Está pronto para ver o IMS Suite em ação? Preencha o formulário abaixo para marcar uma demonstração!