When you’re running complex operations across multiple plants and regions, the day-to-day realities of asset integrity aren’t just about keeping equipment running; they’re about making sure people, processes, and data are working in sync.

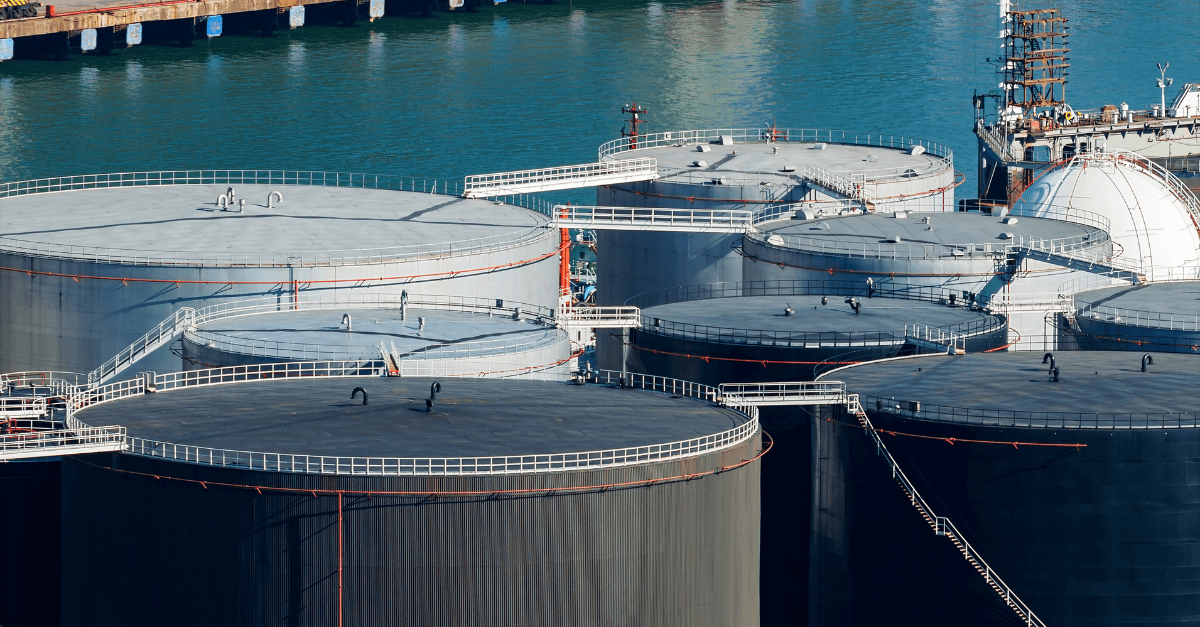

For one global petrochemical company, that balance was becoming harder to maintain. With a broad network of upstream and downstream assets, the organization operates one of the largest integrated chemical networks in its region.

Their plants vary widely in age, scale, and digital maturity. Some sites were equipped with modern systems, while others still depended on legacy infrastructure and manual processes. As the pressure to improve reliability and efficiency grew, it became clear that existing systems couldn’t support the complexity or scale of the challenge.

This business case explores how they addressed those challenges head-on, starting with data, standardization, and frontline execution through IMS PEI and IMS PLSS. The result: simplified systems, measurable impact, and a foundation built to scale.

The Need

Across its global petrochemical operations, the company faced a growing challenge: how to maintain the integrity of aging assets.

Many of their facilities in Asia were operating with decades-old equipment, creating a clear need for more structured inspection planning and repair tracking. Across 20+ sites, there were stark differences in digital maturity. Some plants had advanced systems in place, while others still relied on paper-based workflows and fragmented tools.

On top of this, resource pressures were increasing. Operational budgets were tightening, while expectations to operate at a high production scale and maintain low incident rates remained as high as ever. Teams needed to do more with less: fewer people, less time, and no room for error.

The company’s existing SAP ECC system lacked the depth and flexibility to support efficient integrity management. Data quality issues made it difficult to rely on inspection history or to plan proactively. Without a clean and standardized foundation, there was a risk of carrying process gaps and poor visibility into the planned ERP migration to S/4HANA.

To break this cycle, the company needed a solution that could:

- Standardize integrity practices across a highly diverse global footprint.

- Improve data quality and accessibility for inspection planning and reporting.

- Digitize workflows while remaining flexible for sites with varying levels of readiness.

- Deliver measurable value quickly, independent of ERP timelines.

That’s when they chose Cenosco’s Integrity Management System (IMS), a solution that aligned closely with their priorities to standardize workflows, improve data quality, and scale best practices across all sites.

The Solution

The rollout started small but deliberate. At their pilot site, the team focused first on cleaning up integrity data and digitizing core workflows. This wasn’t about flashy technology or sweeping transformations; it was about getting the basics right: structuring inspection data, eliminating paper-based processes, and equipping teams with the tools to plan and execute effectively.

Once that foundation was in place, they expanded to other plants, tailoring the approach to each site’s level of digital maturity. IMS, with its Pressure Equipment Integrity (PEI) and Pipeline and Subsea System (PLSS) modules, became the backbone for managing asset integrity. It brought mechanical and pipeline integrity teams, corrosion engineers, inspectors, and contractors into a single platform.

To maximize efficiency, IMS was tightly integrated with SAP for planning and reporting, MOC for change management, PI for process data monitoring, and DMS for document control. This created a connected ecosystem where all stakeholders could collaborate seamlessly, replacing fragmented workflows with auditable, ISO-compliant digital practices.

The Result

The impact of the IMS rollout was visible from the very first pilot. By focusing on data quality and streamlined workflows, the company achieved measurable improvements in efficiency, cost, and compliance. All this lays the groundwork for global adoption.

At the pilot site alone, they:

- Reduced corrosion loops from 4,000 to 900, simplifying inspection scope and freeing up engineering resources for higher-value work.

- Saved 500 hours annually in inspection planning and reporting, allowing teams to focus on proactive maintenance rather than chasing paper trails.

- Digitized workflows for pressure vessels, PRDs, and piping systems, ensuring consistency and compliance across all integrity processes.

- Improved access to the latest available data and reporting by consolidating spreadsheets into centralized dashboards.

As IMS scaled across their network, the benefits multiplied:

- Over 1,000 staff globally adopted the new workflows, creating a unified approach to integrity management across 20+ sites.

- The company realized an early-phase cost benefit of ~$2M through optimized inspection intervals and reduced manhours.

- Their application landscape was simplified, reducing reliance on bespoke tools and preparing them for a smoother S/4HANA migration.

Beyond the numbers, IMS brought consistency and confidence to a highly diverse operational environment. Whether at high-maturity plants with advanced automation or sites still transitioning from paper-based systems, teams could now work within the same structured framework, improving reliability, compliance, and decision-making.

The results proved that tackling integrity management early, before major ERP upgrades, not only delivered immediate ROI but also set the stage for long-term operational excellence.

Conclusion

This transformation highlights what’s possible when a pragmatic, data-first approach is combined with the right technology. By focusing on building a strong integrity foundation early, the company unlocked efficiencies, empowered their teams, and set themselves up for future success, long before their ERP upgrade.

Their journey with Cenosco’s IMS shows that standardizing asset integrity management isn’t just a technical upgrade; it’s a strategic move that delivers measurable value and resilience across even the most complex global operations.

Why IMS Is the System Integrity Leaders Count On

Cenosco’s Integrity Management System (IMS) is an enterprise asset integrity platform that helps organizations manage the reliability, integrity and functional safety of critical assets. It provides a unified framework to digitize workflows, standardize practices, and improve data quality across global operations. IMS enables teams to optimize performance, ensure compliance, and achieve operational excellence.

Meet IMS: The Backbone of Smarter, Safer Operations

If this success story resonates with your challenges, don’t wait. Request a demo and find out how IMS can simplify your integrity landscape and accelerate your transformation.