Functional safety has long been viewed as a necessary box to tick, a matter of regulatory compliance. But in today’s environment, where operational efficiency, cost pressures, and digital transformation intersect, it is rapidly becoming a business-critical driver of resilience and performance.

In a recent Cenosco webinar, experts Pieter Poldervaart and Eshel Feller explored how the safety landscape is shifting from compliance-driven obligations to digitally enabled strategies that can redefine efficiency, accountability, and risk management. Their conversation highlighted the challenges companies face – such as fragmented systems, overwhelming data volumes, and tightening regulations – and the opportunities that arise when organizations embrace integrated, auditable, and future-ready solutions.

This blog distills the key insights from their discussion, bringing forward the perspectives that matter most for engineers on the ground, functional safety professionals shaping processes, and executives navigating strategic decisions. If your organization still treats functional safety as a checkbox exercise, this is your chance to rethink what it could mean in the digital era.

From Engineering Task to Business Imperative

The traditional view of functional safety as an engineering silo is fading. Regulatory demands now require companies to prove compliance throughout the entire safety lifecycle, from hazard assessment to decommissioning. Managing the massive volume of documents, test records, and design data has become nearly impossible with fragmented tools and manual processes.

This shift is pushing companies to adopt integrated software platforms that unify the safety lifecycle. By consolidating hazard analysis, SIL determination, proof testing, and change management into one environment, organizations ensure compliance and increase efficiency across disciplines.

Why Auditability and Traceability Matter

In high-risk industries like oil and gas, chemicals, and power generation, auditability and traceability are the foundation of trust. They provide the ability to prove that safety processes are in place and are performed consistently, for the right reasons, and at the right frequency. Being able to answer questions such as “Was this risk assessment justified?” or “Are we testing equipment often enough to prevent failure?” is essential for regulators, insurers, and internal stakeholders alike.

Auditability means that every decision, from a hazard study to a maintenance change, can be tracked and verified. Traceability ensures that one step in the lifecycle clearly flows into the next. For example, the outcomes of a HAZOP feed into a LOPA, which then guides the design of safety instrumented functions and ultimately dictates proof testing intervals. Without this continuity, organizations lose visibility, and visibility is what underpins safe, reliable operations.

The cost of neglecting this is high. The webinar shared a real-world case where weak traceability around valve testing frequencies led to two gas release incidents in the same facility within days. When regulators investigated, the company could not explain why valves were tested only every four years. They had no documented justification or auditable reasoning behind the interval. The result was safety risks and forced rework: the site had to redo every hazard and LOPA study from scratch, recalculating and revalidating all safety instrumented functions at significant cost and stress.

Best practices are starting to take shape. Clear documentation of every step, adoption of electronic lifecycle management tools that centralize information, and a disciplined approach to change management create the backbone of an auditable and traceable process. When done well, these practices move auditability from being a compliance burden into a driver of continuous improvement and resilience.

Balancing Standards and Customization

Standards such as IEC 61508 and IEC 61511 define the principles of the safety lifecycle. Still, the path to compliance is rarely identical across companies or different plants within the same organization. Every site carries its legacy IT systems, homegrown templates, and established working methods. What works in one environment may not be practical in another.

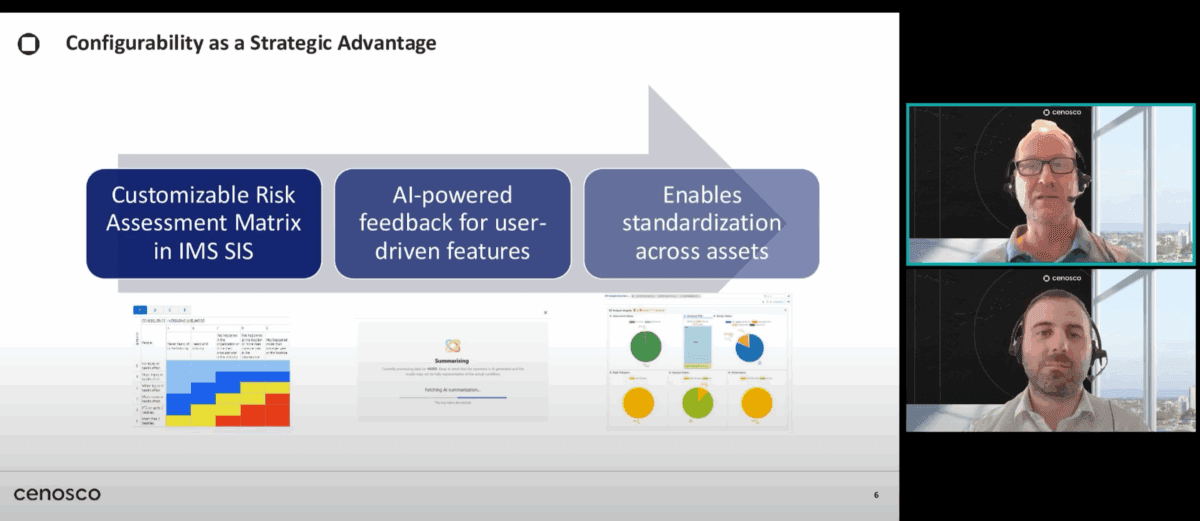

This creates a delicate balance. Software tools must be consistent enough to uphold the integrity of the standards, but flexible enough to reflect the realities of day-to-day operations. A rigid, one-size-fits-all solution risks clashing with established workflows, while uncontrolled customization can undermine compliance. The most effective approach is a balance: enforce the standards’ fundamentals while allowing customization where it adds value.

A practical example comes from risk assessment matrices. Different organizations may classify risk in different ways, using unique tolerability criteria or company-specific thresholds. Best-in-class tools now allow users to define the number of rows and columns, set their own colors and text, and align the matrix with internal policies. This flexibility ensures that the tool adapts to the organization’s needs while standardizing risk management across all sites and assets.

The key is listening to end users and understanding why a feature is needed. Is it a nice-to-have or is it essential for compliance and operational effectiveness? By making this distinction, organizations can achieve both consistency and adaptability without compromising safety.

Integration as a Strategic Enabler

In today’s operational environment, integration is no longer a luxury but a necessity. Functional safety does not live in a vacuum. It relies on data scattered across systems: CMMS platforms, SAP, engineering tools, data historians, and process control systems. Engineers are forced to manually migrate information from one place to another if these systems are not connected. This introduces delays, duplication of effort, and the risk of human error.

Modern software is beginning to close these gaps through APIs and digital data collection tools. Proof test results from the field can flow automatically into maintenance schedules, while approval logs, revision histories, and event records are synchronized in real time. This reduces administrative overhead and provides managers and engineers with actionable insights through dashboards and KPIs.

The real value lies in turning data into intelligence. Design assumptions about failure rates or demand frequencies can now be checked against real-world operational data. Instead of living in separate silos, safety studies and field performance are connected, allowing organizations to validate their assumptions and adjust in real time.

Integration is not just about linking systems. It is about building the bridge between assumptions and reality, between compliance and performance. When done effectively, it allows functional safety to move beyond being a checklist exercise and become a driver of efficiency, accountability, and business outcomes.

Trends Shaping Functional Safety

Functional safety is moving fast toward a more connected, intelligent future. From the insights shared during the Cenosco webinar, two major trends are already reshaping how companies approach safety in the digital era.

1. Data-Driven Decision Making

Integration is unlocking new ways of working. Companies can now validate those assumptions with live operational data instead of relying solely on assumptions made during design, such as expected failure rates or demand frequencies. Organizations can continuously refine their safety models by connecting safety studies with real-world proof test results.

This shift opens the door to proactive risk intelligence. Imagine a plant manager starting the day by viewing a live risk heatmap of their facility, immediately seeing where vulnerabilities lie. Meanwhile, engineers and functional safety specialists could receive targeted insights relevant to their role, such as deviations in proof test performance or anomalies in system availability. This step-change from compliance reporting to decision support allows leaders to act on risk before it escalates.

2. Cloud-First Collaboration

As engineering and operations are often spread across continents, cloud technology is becoming indispensable. It enables teams in different locations to work in the same digital environment, sharing up-to-date information without delays or version conflicts. This is particularly valuable when safety design, operations, and maintenance are managed by different teams or even external contractors.

The benefits go beyond collaboration. Cloud adoption also strengthens cybersecurity by aligning with standards like IEC 62443, equipping organizations to defend against increasingly sophisticated threats. For IT leaders, it provides a more agile and future-proof infrastructure that can scale with organizational needs. For safety professionals, it means having reliable, accessible data at their fingertips wherever they are in the world.

Beyond Compliance

The digital era is redefining what functional safety means for high-risk industries. Treating safety as a checklist item to satisfy auditors is no longer sufficient. The companies that will thrive are those that recognize functional safety as a strategic enabler of resilience, efficiency, and trust.

Transparent, adaptable, and connected systems allow organizations to move beyond minimum requirements. They enable safety data to drive better decisions, reduce inefficiencies, and strengthen the overall integrity of operations. For executives, this means rethinking functional safety not as a regulatory cost but as a competitive advantage that safeguards people and performance.

These themes will be at the forefront of the Reliability, Integrity, and Functional Safety Summit in Cologne on September 29, 2025. The conversation is no longer about whether to embrace integration, auditability, and digital transformation, but how quickly and effectively organizations can do so. The future belongs to those who see functional safety not as a burden, but as an opportunity to lead.

Prêt pour une démonstration ?

Êtes-vous prêt à voir la suite IMS en action ? Remplissez le formulaire ci-dessous pour réserver une démonstration !