A Small Vibration, A Big Loss

This is not a hypothetical scenario—it’s a real event that cost a company tens of millions of dollars.

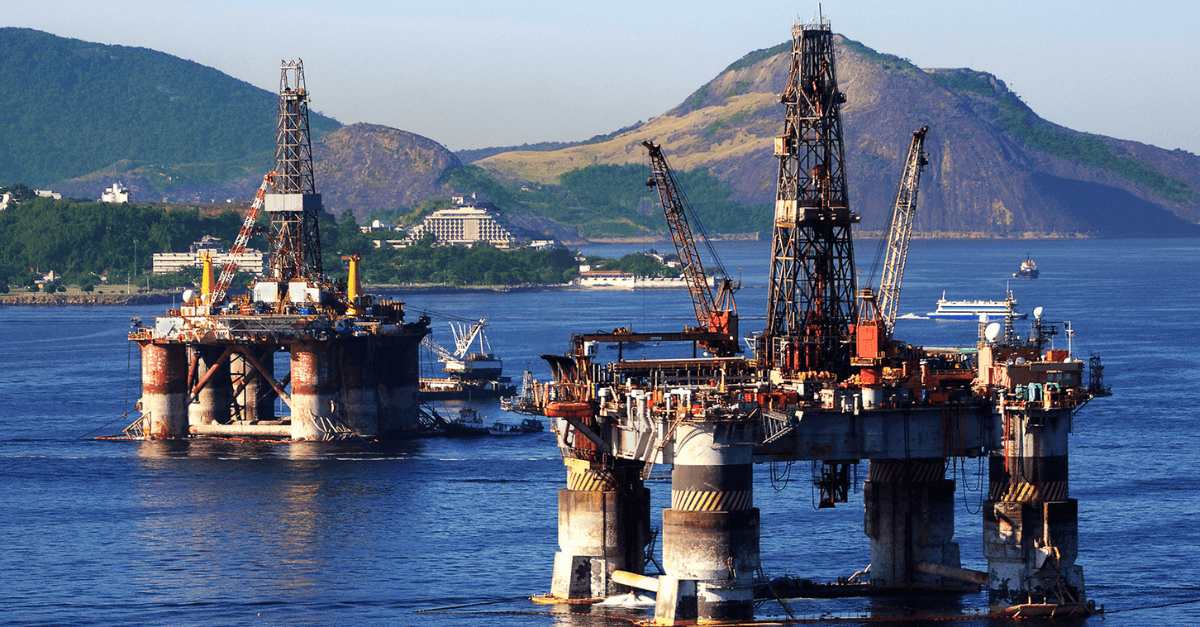

An offshore platform, which had been running smoothly for years, was thrown into chaos by a seemingly minor issue. One morning, an operator noticed a slight increase in vibration from a critical compressor. It wasn’t alarming – just a small deviation. But it was enough to raise an eyebrow. Despite the concern, the decision was made to monitor it rather than take immediate action.

Fast forward a few weeks. That small anomaly has snowballed into a catastrophic failure, halting production for ten days. The financial toll? $40 million in lost production revenue alone. Add to that the ripple effects: missed delivery contracts, regulatory penalties, increased insurance premiums, and higher compliance costs. The total cost of this failure could easily run into tens of millions.

And here’s the kicker: This wasn’t some unforeseen disaster. This failure was entirely preventable.

The Vicious Cycle: Why It Happens

Why do these costly failures continue to plague the industry, despite our access to technology that could help us predict and prevent them? The answer often lies in our outdated approach to maintenance. In many cases, companies still rely on reactive maintenance – waiting for a problem to arise and then addressing it. While this method might work in some situations, it’s a recipe for disaster in critical operations.

In theory, predictive maintenance promises to identify and prevent failures before they occur by using data-driven models. However, the reality is that implementing predictive maintenance can be highly challenging. Predicting exactly when a failure will occur, or whether a minor anomaly will escalate into a major breakdown, isn’t always as straightforward as it sounds. Even with sophisticated sensors and software, predictive models can be inaccurate, especially when dealing with complex systems that operate in unpredictable environments.

The irony is that while predictive maintenance has potential, many operators struggle with its practical application, and some prefer a more reliable alternative – preventive risk-based maintenance. This proactive approach focuses on identifying and addressing potential risks before they become problems, which is more in line with industry needs.

The Real Cost of Doing Nothing

When a failure like this occurs, the financial impact is far-reaching. The immediate loss of production is the most obvious cost. However, what’s less talked about are the hidden costs that follow:

- Missed delivery contracts: For offshore oil and gas operations, time is money, and missing contracts means not just lost revenue but also reputational damage that can take years to recover from.

- Regulatory penalties: Depending on the severity of the downtime, companies may face stiff fines from regulators, especially if they fail to meet safety or environmental standards during the outage.

- Increased insurance and compliance costs: Every failure raises the risk profile of a company, which in turn drives up insurance premiums and compliance requirements. Over time, this can add millions to a company’s annual operating costs.

- Damage to reputation and stakeholder trust: Unplanned downtime isn’t just a financial burden; it can also erode the trust of investors, customers, and other stakeholders who depend on the company to deliver consistent, reliable results.

Predict, Prevent, and Preserve

It doesn’t have to be this way. The good news is that companies can take a more proactive approach to avoid unplanned downtime – through preventive risk-based maintenance. Instead of waiting for failure to occur, this strategy helps identify and address risks before they develop into costly problems.

By using data, insights, and thorough risk assessments. Unlike predictive maintenance, which can sometimes lead to uncertainty and costly interventions, preventive maintenance strategies focus on minimizing risk in a more controlled and predictable way.

In other words, it’s about making the leap from reactive to proactive, from risk management to risk prevention.

These tools and approaches enable operators to:

- Prevent anomalies from occurring in the first place: Performing timely maintenance based on risk helps ensure reliability, minimize downtime, and avoid costly failures.

- Prevent failures from escalating into full-scale shutdowns: With preventive maintenance strategies, teams can schedule repairs or adjustments before they affect production, reducing the risk of unplanned downtime.

- Maximize uptime and ensure compliance: By preventing unplanned outages, companies can keep production running smoothly while staying in compliance with industry regulations, reducing penalties and fines.

In other words, it’s about making the leap from reactive to proactive, from risk management to risk prevention.

What’s Your Strategy?

The truth is, every oil and gas facility, every industrial plant, faces this choice: Will you wait for failure, or will you prevent it?

The cost of doing nothing is staggering. Predictive maintenance can help detect problems, but it often leads to uncertainty – should you act now or wait? Preventive maintenance removes this guesswork by addressing risks before they turn into failures. It focuses on reliability, reducing downtime, and ensuring safer, more efficient operations. Instead of reacting to breakdowns, companies need to take a proactive approach to protect their assets and avoid unnecessary losses. The question isn’t whether technology can help – it’s whether the industry is ready to embrace change. And whether it’s worth risking another billion-dollar problem before we do.

Stay Ahead of Costly Downtime

Get more industry insights and real-life stories delivered straight to your inbox by signing up to our newsletter.