IMS platform unifies your integrity data, workflows, and insights into one strategic, scalable system.

Intelligent Maintenance

IMS RCM brings discipline-level clarity to preventive maintenance.

Many organizations struggle with unplanned downtimes, high maintenance costs, and lack of a streamlined process.

•Eliminate duplicative or ineffective PMs

•Highlight overburdened assets via MEI scoring

•Standardize task logic across mechanical, rotating, E&I, and SIS systems

•Rationalize intervals based on real degradation behavior—not OEM guesswork

行业领先的软件

IMS RCM

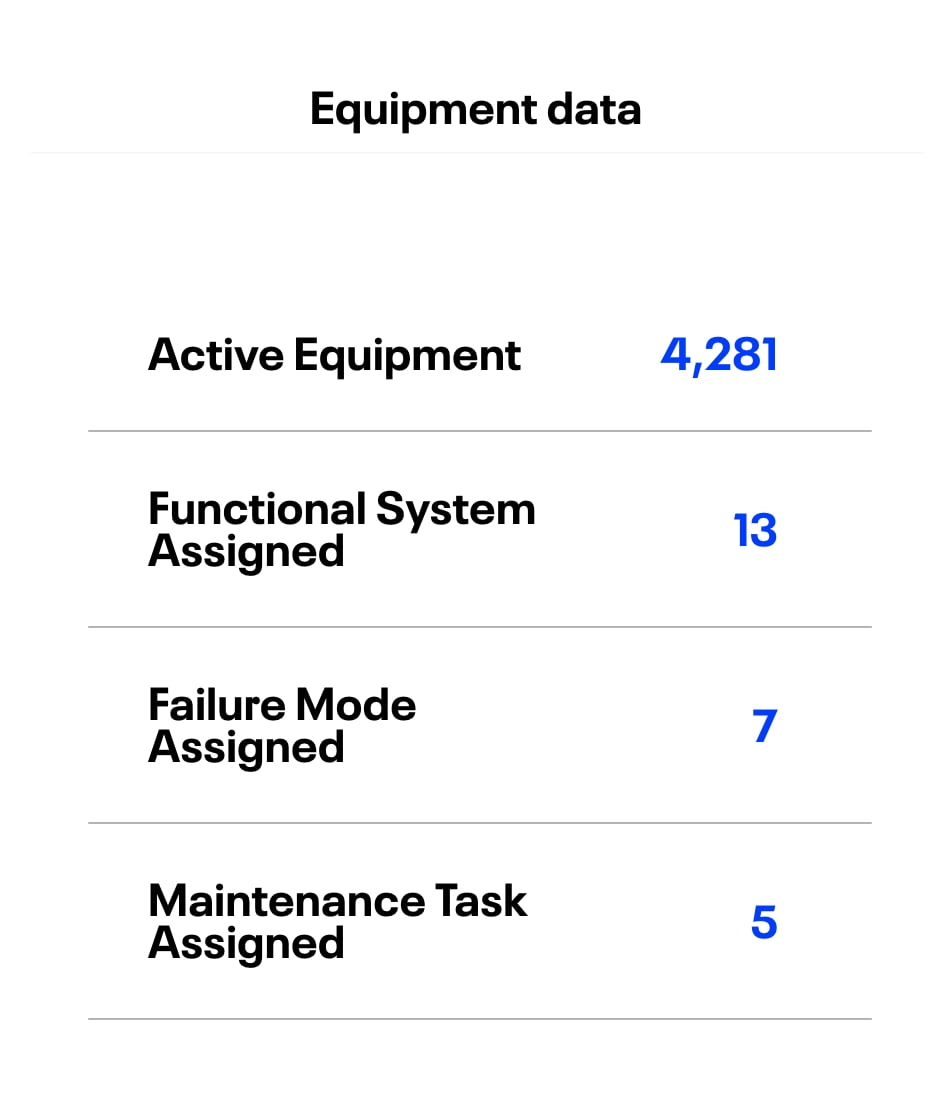

IMS RCM (Reliability-Centered Maintenance) is cloud-based software which implements the RCM Methodology to optimize maintenance tasks through risk-based prioritization, ensuring safe and cost-effective operations.

•107,000+ RCM analyses in action

•83,000+ failure-finding tasks optimized

•MEI scoring, FMEA logic, and audit-ready justifications built-in

All in a unified, modular platform trusted by global operators.

Whether through comprehensive RCM2 analysis or utilizing our library of maintenance strategy templates, IMS RCM allows the integration of FMEA (Failure Mode and Effects Analysis) to provide the insights you need for effective, budget-friendly asset management.

深受行业领导者信赖

IMS doesn’t just track integrity. It delivers it across pressure systems, structures, rotating equipment, and maintenance programs.

- 最佳 维护成本

- 证明 和预定义的维护库

优化预防性维护战略

IMS RCM transforms over-maintenance into optimized reliability. Using failure mode analysis (FMEA), MEI scoring, and performance-based intervals, operators cut 8,000+ redundant PMs, reducing “task fatigue” and reclaiming over $1M annually. By reprioritizing 10% of maintenance tasks and avoiding premature repainting or over-design, operators save big—especially in harsh climates.

预约电话The integrity software standard

查看我们的以可靠性为中心

运行中的维护软件

Join the ranks of operators using IMS to manage complexity, avoid downtime, and maintain full compliance—from initial build to long-term operations.

Get started with a demo!