Liquefied Natural Gas (LNG) is no longer just a niche player in the global energy landscape. It has become one of the cornerstones of the ongoing energy transition, bridging the gap between traditional hydrocarbons and renewable sources. LNG provides a cleaner, more flexible alternative to coal and oil, and its ability to transport energy efficiently across continents has made it indispensable in balancing regional supply and demand. During our latest Asset Integrity webinar, Amit Singh and Ahmed Sakr shared their experience managing the mechanical integrity of LNG facilities. Together, they discussed the unique risks, material challenges, and degradation mechanisms that make LNG asset integrity a highly specialised discipline.

Why LNG Integrity Matters

LNG plants operate at extreme conditions that stretch both materials and human expertise. Temperatures in the liquefaction process can drop to around –162°C, while operating pressures remain very high. These combined extremes create a highly demanding environment where a slight deviation from safe operating parameters can lead to a significant loss of containment. Such incidents can be catastrophic, both in terms of safety and environmental impact, and can result in prolonged unplanned downtime, regulatory scrutiny, and severe financial loss.

An effective mechanical integrity program for LNG facilities, therefore, serves as more than a regulatory requirement. It is the backbone of safe and reliable operations. A well-designed integrity management framework allows operators to detect early signs of material degradation, optimise inspection intervals, and reduce the likelihood of sudden failures that are difficult to predict.

Beyond safety, the benefits extend into performance and economics. A mature integrity program improves uptime, enhances overall plant efficiency, and supports continuous compliance with international and local standards. As Amit explained, by combining structured inspection planning with digital integrity tools, operators can ensure that their LNG assets perform reliably throughout their entire lifecycle.

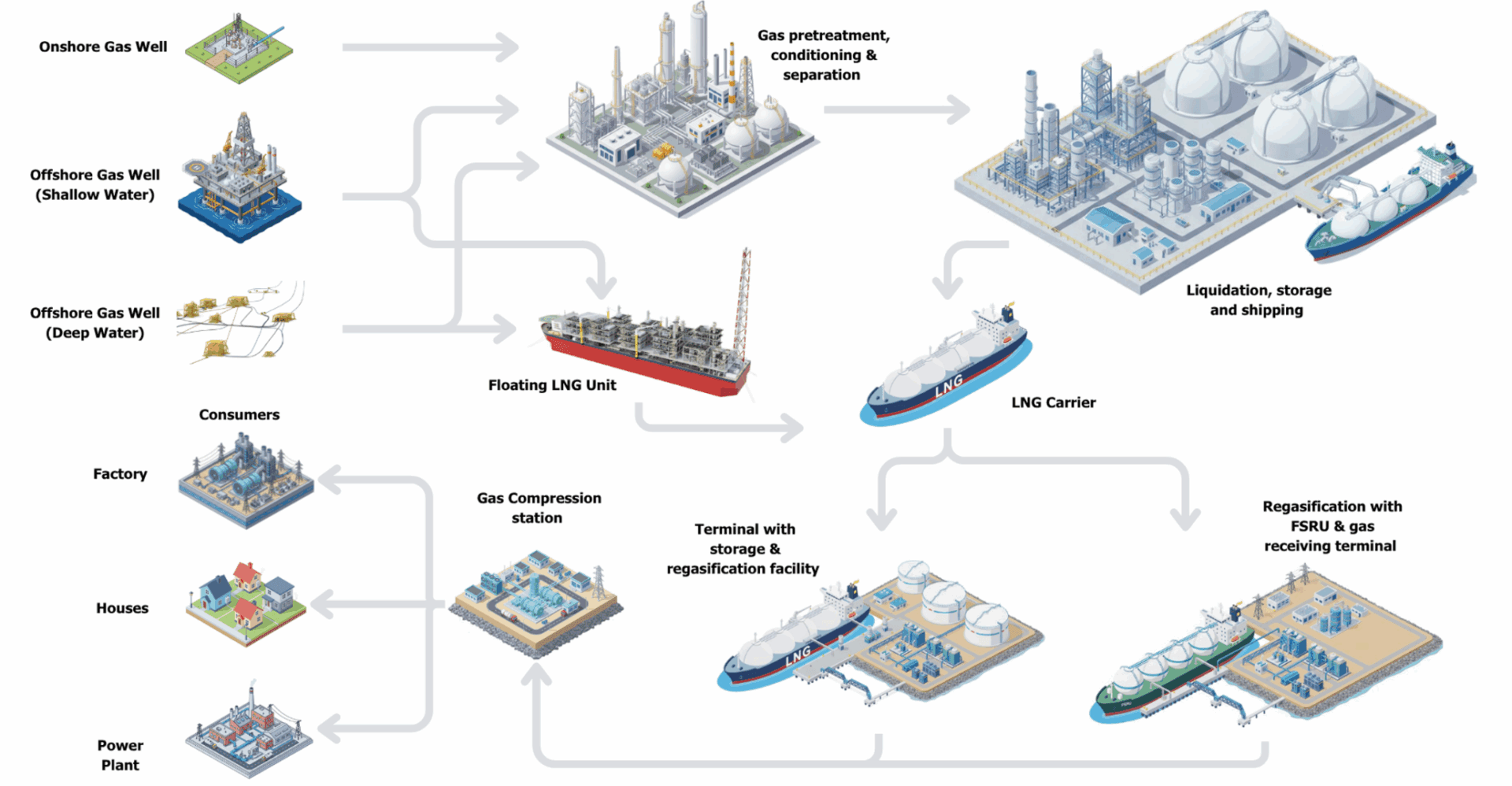

Understanding the LNG Supply Chain

The LNG value chain is a remarkable combination of complex engineering systems, high-capacity logistics, and precision operations. Each segment of the chain, starting from raw gas extraction and proceeding through gas treatment, liquefaction, transportation, storage, and regasification, presents its own integrity challenges. Managing these challenges effectively requires a deep understanding of both process design and the material limits of the assets involved.

At the start of the chain, gas pre-treatment units play a crucial role in removing impurities such as H₂S, CO₂, mercury, and water vapour. These contaminants can have severe corrosive effects or create safety hazards under cryogenic conditions. Once the gas meets the required specifications, it is sent to the liquefaction unit, which is the thermodynamic heart of an LNG plant. This section of the facility transforms natural gas, primarily composed of methane, into a liquid state by cooling it to cryogenic temperatures using advanced refrigeration cycles. The performance and reliability of compressors, heat exchangers, and cryogenic piping systems in this unit directly affect the plant’s overall efficiency and availability.

Further down the chain, the storage and transport systems, including massive cryogenic tanks and double-hulled LNG carriers, must maintain integrity under continuous thermal cycling, pressure variation, and vibration. The tanks themselves are constructed from specialised materials such as 9% nickel steel and austenitic stainless steels, which can withstand extremely low temperatures while retaining sufficient ductility. According to Ahmed, the smooth functioning of this interconnected network depends on how well every segment of the chain aligns. A weakness at any point, whether due to poor design, improper operation, or delayed maintenance, can disrupt the flow of energy and compromise both safety and profitability.

LNG in the Global Energy Mix

Natural gas currently provides around a quarter of the world’s total energy supply, and roughly thirteen per cent of that volume is traded in the form of LNG. This figure continues to rise each year as more countries invest in LNG infrastructure to diversify their energy portfolios. Asia remains the focal point of global demand, led by China, Japan, and South Korea, but new markets are rapidly emerging in Europe, the Middle East, and Africa. On the supply side, North America has become a dominant exporter due to its abundant shale gas resources and expanding liquefaction capacity.

The scale of the LNG industry is expanding at an unprecedented rate. Today, global liquefaction capacity exceeds 490 million tons per year, with an additional 210 million tons expected to come online by 2026. The fleet of LNG carriers now surpasses 740 active vessels, and more than 300 new ships are under construction. This growing network demonstrates the central role of LNG in future energy strategies, but it also magnifies the need for robust and standardised integrity management practices across the industry. As new plants are commissioned and older ones approach the end of their design life, maintaining mechanical integrity becomes an ever more complex and data-intensive challenge.

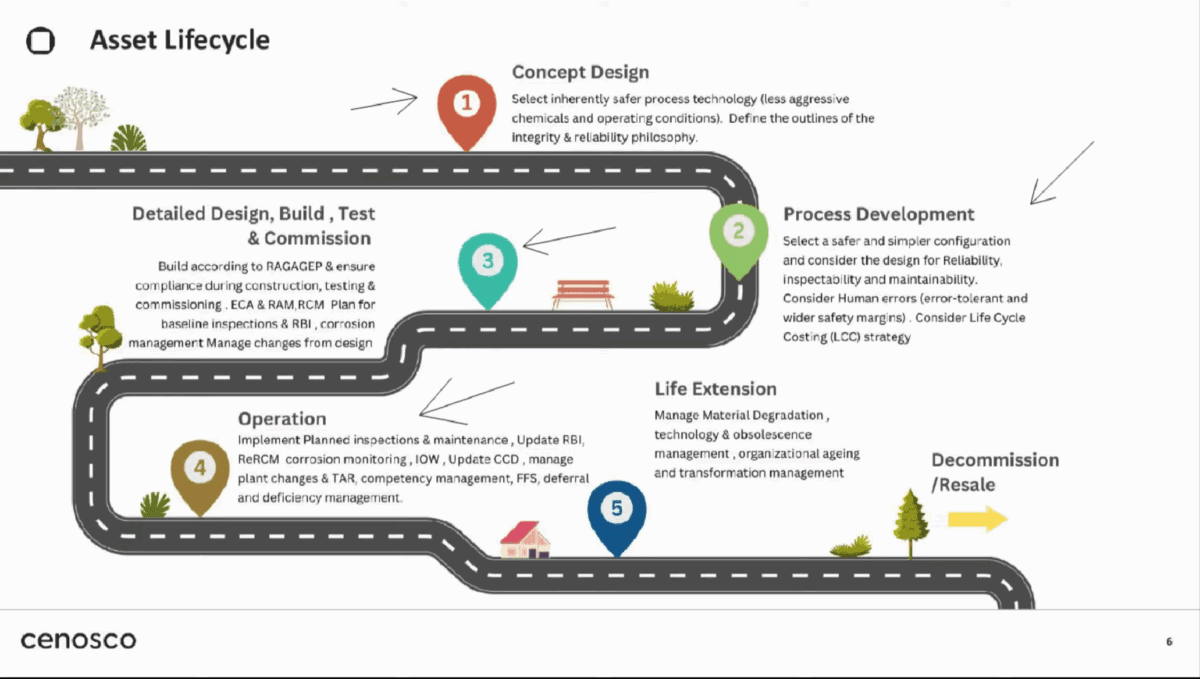

Integrity Across the Asset Lifecycle

Mechanical integrity is not something that can be retrofitted once operations begin. It must be embedded from the earliest stages of an asset’s lifecycle. During the concept and design phases, engineers define the reliability and integrity philosophy of the facility. This involves selecting appropriate materials, evaluating process configurations, and incorporating lessons learned from similar installations. Decisions made at this stage influence not only capital expenditure but also the long-term maintenance costs and operational risks.

In the construction and commissioning phase, integrity and reliability activities such as baseline inspections, initial risk-based inspections (RBI), reliability-centred maintenance (RCM) studies, and corrosion management plans must be implemented. Establishing these early creates the foundation for accurate monitoring later in the asset’s life.

Once the facility transitions into operation, these initial studies evolve. Real-time data, process histories, and inspection results allow operators to refine risk models, adjust inspection frequencies, and manage turnaround planning more efficiently. This approach ensures that integrity management remains dynamic and responsive to operational realities. As Ahmed noted, beginning the integrity journey early provides operators with a strategic advantage. It minimises costly surprises and allows data-driven decisions that directly support asset longevity and profitability.

Materials and Degradation Mechanisms

The selection of materials for LNG facilities is primarily driven by the need to withstand extreme temperatures without compromising strength or ductility. Cryogenic heat exchangers are often made of stainless steel or aluminium alloys, while process vessels may use nickel alloys or specialised low-temperature carbon steels. Each material, while offering specific advantages, introduces its own degradation behaviours that must be closely monitored.

Degradation mechanisms in LNG plants are generally classified as either age-related or non-age-related. Age-related mechanisms, such as CO₂ corrosion, H₂S corrosion, and microbiologically influenced corrosion, progress gradually and can be predicted using conventional inspection and monitoring methods. Non-age-related mechanisms, however, are more insidious. They occur suddenly, without a defined rate, and can cause rapid failures. These include brittle fracture, liquid metal embrittlement, and chloride stress corrosion cracking (SCC).

Brittle fracture, for example, can occur when equipment is exposed to temperatures below the material’s ductile-to-brittle transition temperature. In such cases, even a minor stress concentration can result in catastrophic failure. Liquid metal embrittlement is another critical concern, particularly when trace amounts of mercury interact with aluminium heat exchangers or carbon steel components. Similarly, chloride SCC tends to affect austenitic stainless steels at temperatures above 60°C in chloride-rich environments, leading to sudden cracking that is extremely difficult to detect visually. Each of these mechanisms requires not only careful material selection during design but also continuous process monitoring during operation.

The Role of Integrity Operating Windows (IOWs)

To manage these risks effectively, LNG operators rely on Integrity Operating Windows (IOWs), which define the safe operational boundaries for parameters such as temperature, pressure, chemical concentration, and flow velocity. IOWs serve as early warning systems that alert engineers when process conditions deviate from established limits. In many cases, especially for cryogenic systems, monitoring IOWs may be the only practical way to ensure that the mechanical integrity of the equipment is not compromised.

By continuously tracking IOWs through connected data systems, operators can identify deviations before they lead to damage. When integrated within Cenosco’s IMS Suite, these data streams can be linked directly to RBI models, inspection programs, and maintenance planning modules. This integration allows for automated alerts, faster root-cause analysis, and timely corrective actions. The result is a proactive integrity management strategy that not only prevents equipment failures but also helps extend the life of critical assets. Amit summarised it best by stating that managing integrity in LNG facilities requires moving beyond traditional inspection routines toward continuous insight, driven by live process data.

Looking Ahead

The LNG sector is poised for continued growth, but with expansion comes complexity. Many existing plants are approaching or surpassing their original design life, bringing issues such as material degradation, technological obsolescence, and organisational ageing to the forefront. In some facilities, critical equipment may no longer have OEM support or readily available spare parts, while experienced personnel with decades of knowledge are beginning to retire. Addressing these challenges requires a combination of technology, process discipline, and active knowledge transfer.

Digital solutions, such as IMS, play an increasingly vital role in managing this transition. By centralising inspection data, automating risk evaluations, and integrating live operational data, IMS enables asset owners to maintain oversight of both ageing and new infrastructure. In a landscape where LNG continues to power industries and communities worldwide, the ability to manage mechanical integrity through intelligent, connected systems will define the difference between merely operating and operating safely, efficiently, and sustainably.

Готовы к демонстрации?

Вы готовы увидеть IMS Suite в действии? Заполните форму ниже, чтобы заказать демонстрацию!