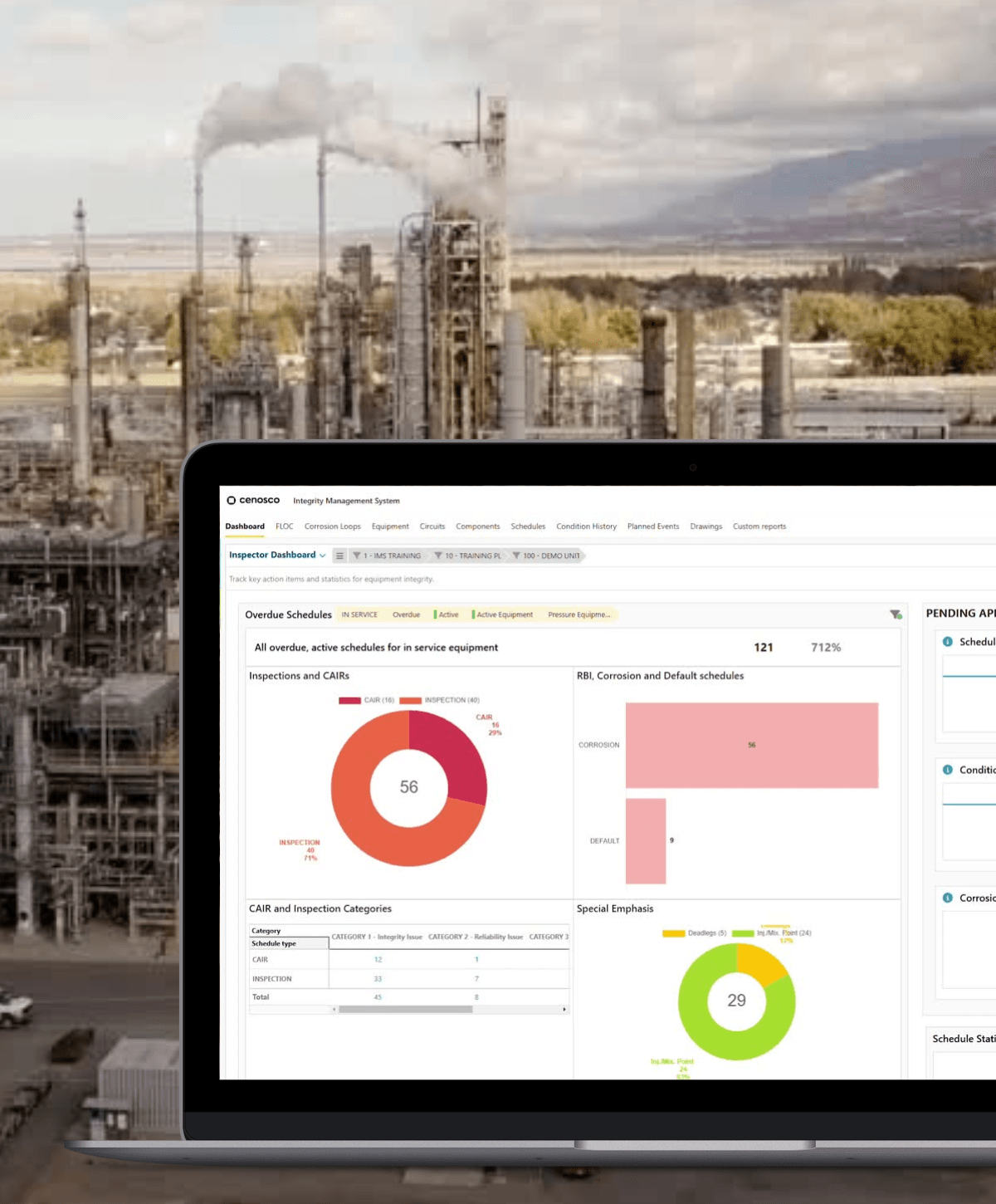

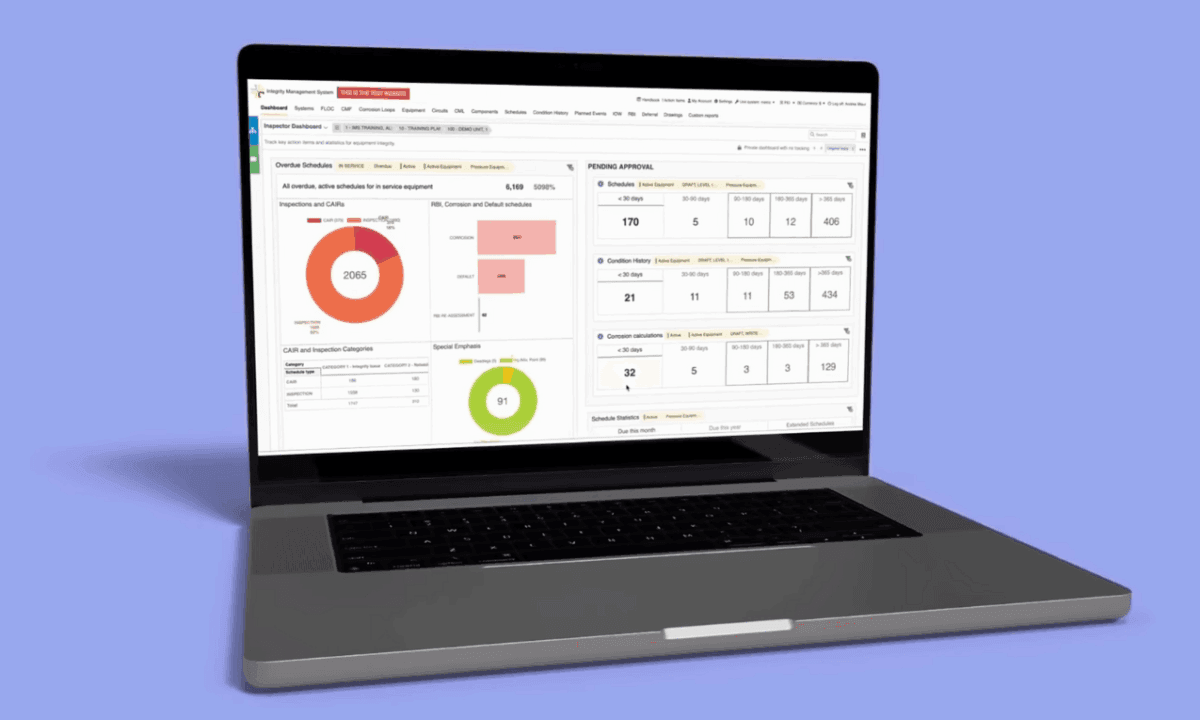

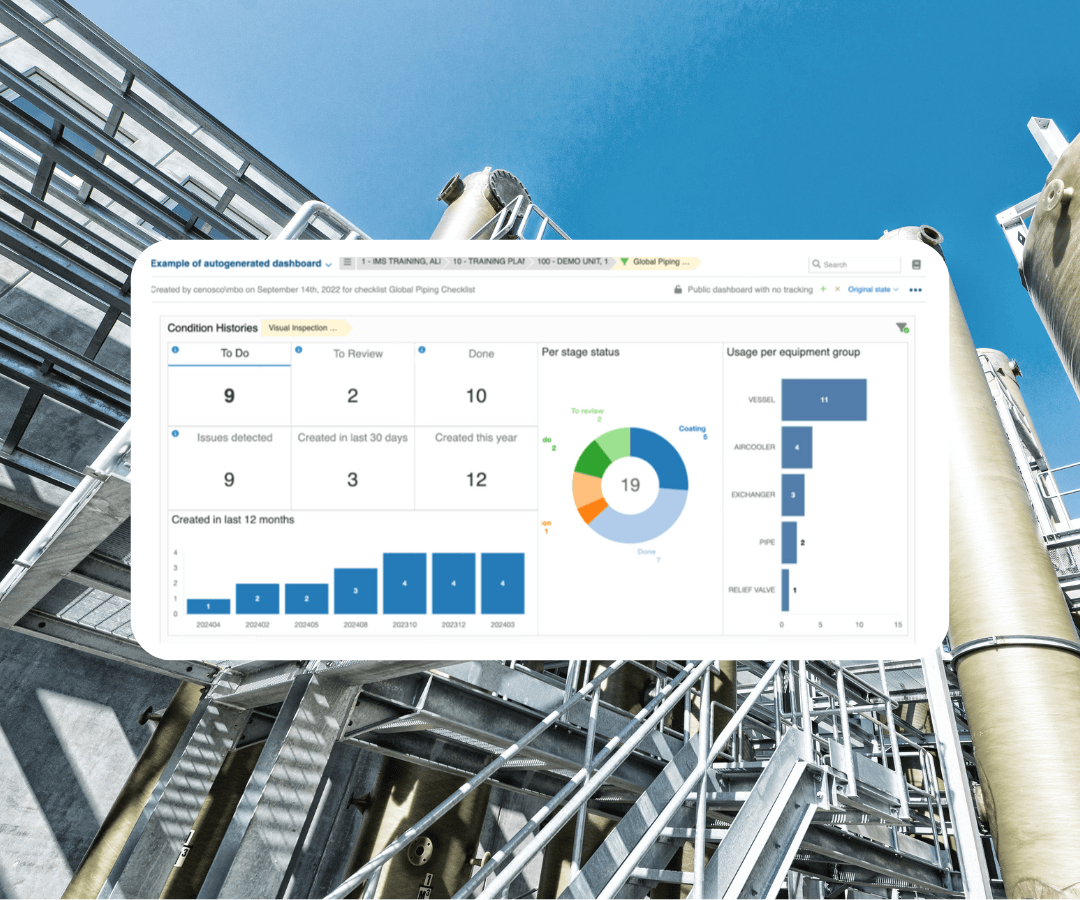

Simplify compliance with intuitive dashboards

IMS Suite simplifies compliance with intuitive dashboards that provide clear insights, helping you stay on top of regulations effortlessly.

IMS SuiteCenosco IMS is an enterprise-grade platform

Preserving critical knowledge by centralizing global integrity data, reducing reliance on individuals, empowering them to do more with less and focus on critical assets

Enterprise grade: Trusted by industry leaders, proven at scale – IMS is already running at the largest O&G and chemical assets worldwide

Engineering depth: IMS is designed by industry experts to reduce risk, manage data at scale, and make complex integrity management simple

No more data silos: Full asset lifecycle visibility – IMS connects engineering & operations, centralizing data across all sites, systems, and teams. Integrates seamlessly with SAP, Maximo, EAM, document management and process historians

Trusted worldwide

Industries we serve

Streamline your operations

The IMS Suite supports users in making smart inspection and maintenance decisions to increase safety, asset availability, performance and optimize management costs.

Request a Demo

Industries

For Oil & Gas, Chemicals and more

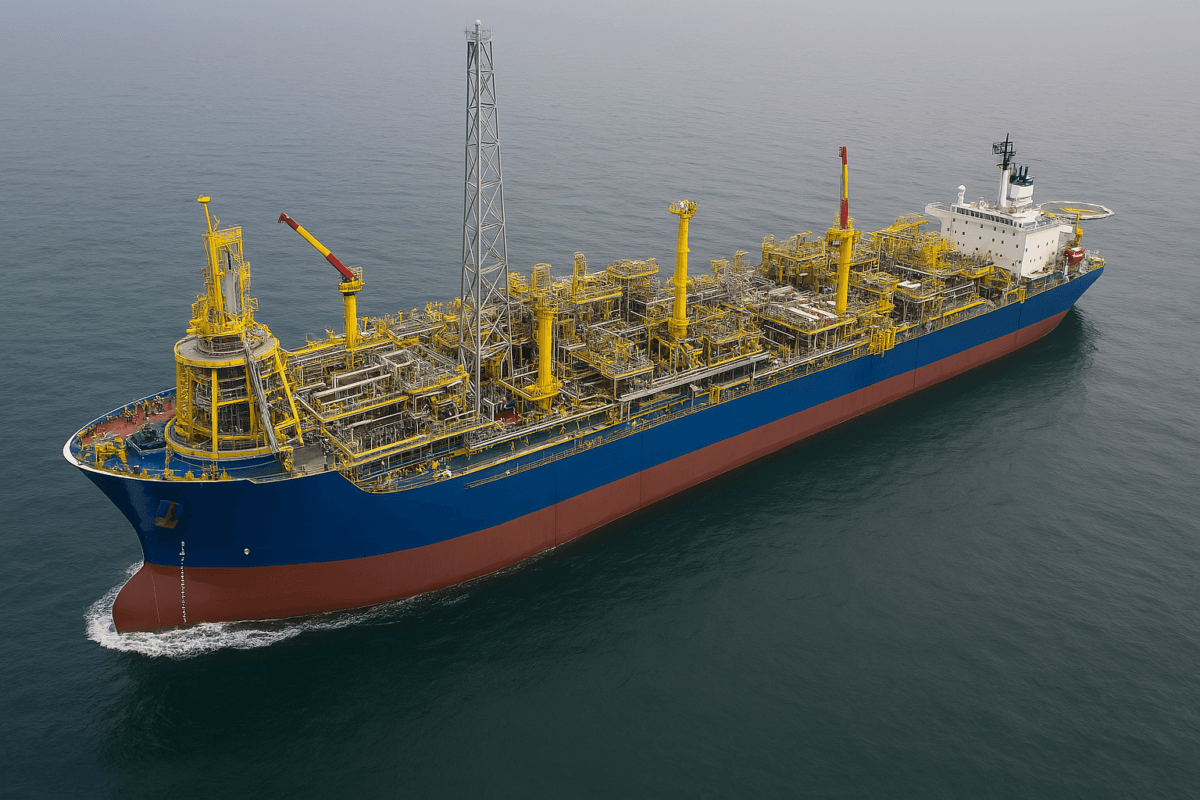

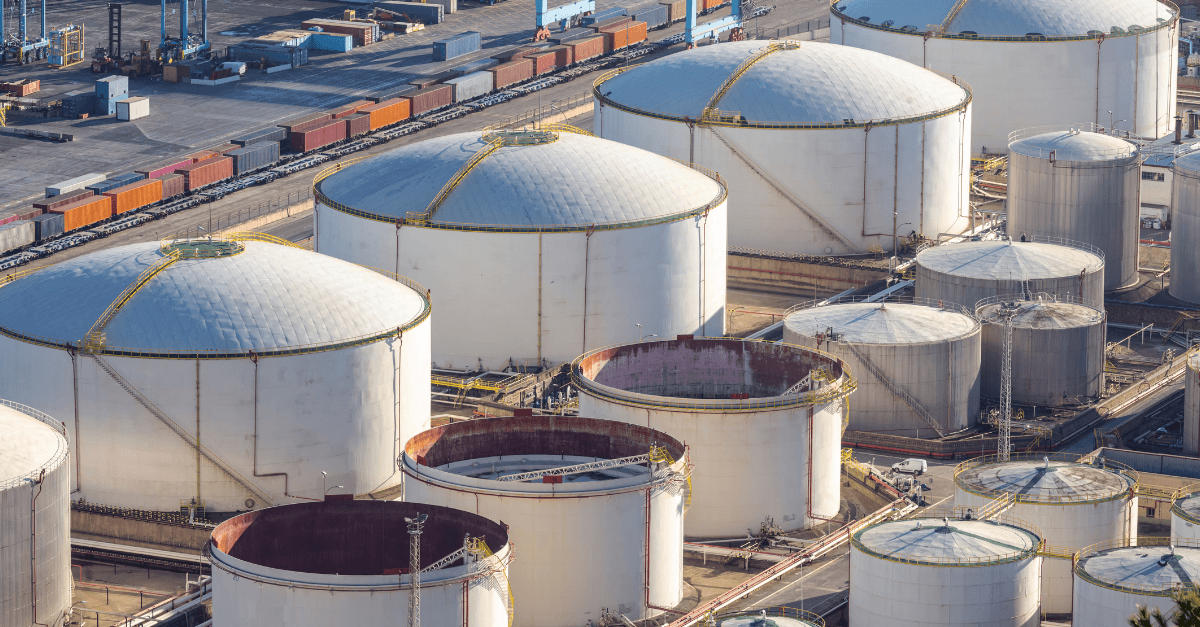

Asset-heavy industries relay on effective asset management, including maintenance, integrity management, and risk management. Our asset integrity software can be used to protect your plant operations both onshore and offshore.

Our IMS Suite offers industry-proven methodologies, intuitive dashboards, and data-driven insights to improve operational efficiency and reduce risk.

Our asset integrity solutions

Filter equipment

Pressure Equipment

Pipelines

Civil

Electrical

Rotating

Services

Every step

of the way

Cenosco offers a variety of services to accompany you along your journey. From implementation and data migration to get you up and running as quickly as possible, to lifetime support to ensure you’re always operating as you expect.

ServicesBusiness Cases

Specialized Software for Oil & Gas and Chemicals

Find out how Cenosco’s asset integrity management software has helped leading companies word-wide, including Shell, NSRP, ThaiOil, NAM and many more.

Explore cases

Our mission

To enable a safe and smart environment

We aim to enable and empower a smart and safe environment for our customers, through the use of our solutions. Giving them a digital transformation that will transform their operational ecosystem into an efficient, effective and reliable one.

ABOUT CENOSCO

Safeguarding assets around the world for over twenty years.

Full control over asset integrity

Our powerful asset integrity software suite gives our worldwide users full control over their integrity and reliability risks. At the core of our operations lay our people, a bright group that behaves innovative and plays as a team. Upgrade your maintenance maturity from reactive to predictive.

About us