Asset Performance Management (APM) software is a type of technology solution used by organizations to monitor, analyze, optimize, and manage the performance of their physical assets.

These assets can include machinery, equipment, infrastructure, and other critical components of a business’s operations.

The primary goal of Asset Performance Management software is to enhance the reliability, efficiency, and overall performance of these assets throughout their lifecycle.

Index

AIM and APM: What is the difference?

Essential Buyer’s Guide to Asset Integrity Management Software

Asset Performance Management Software in the Oil & Gas and Chemical Processing Industries

Frequently Asked Questions

AIM and APM: What is the difference?

Asset Integrity Management (AIM) and Asset Performance Management (APM) are frequently mistaken for each other due to their resemblances, even though they are two separate methodologies.

To ensure the operational effectiveness of your equipment, it’s crucial to establish effective maintenance and inspection plans. Asset Integrity Management (AIM) solutions offer the capabilities needed to determine the optimal intervals for interventions and develop streamlined maintenance strategies.

This makes AIM an essential tool for businesses engaged in asset-intensive sectors, where equipment malfunctions can result in not only significant costs but also pose severe risks to both workers and the environment.

Asset Performance Management (APM) functions more as a framework, often seen as an additional stage following Asset Integrity Management. It serves to monitor the overall performance of an asset; however, it does not provide guidance for maintenance, inspections, or other integrity assessments that might be necessary to ensure optimal production and on-site safety.

As a result, while implementing an Asset Integrity Management solution is a necessity, having Asset Performance Management can be considered an additional enhancement.

Read more about this topic in our blog post: AIM and APM: What is the difference?

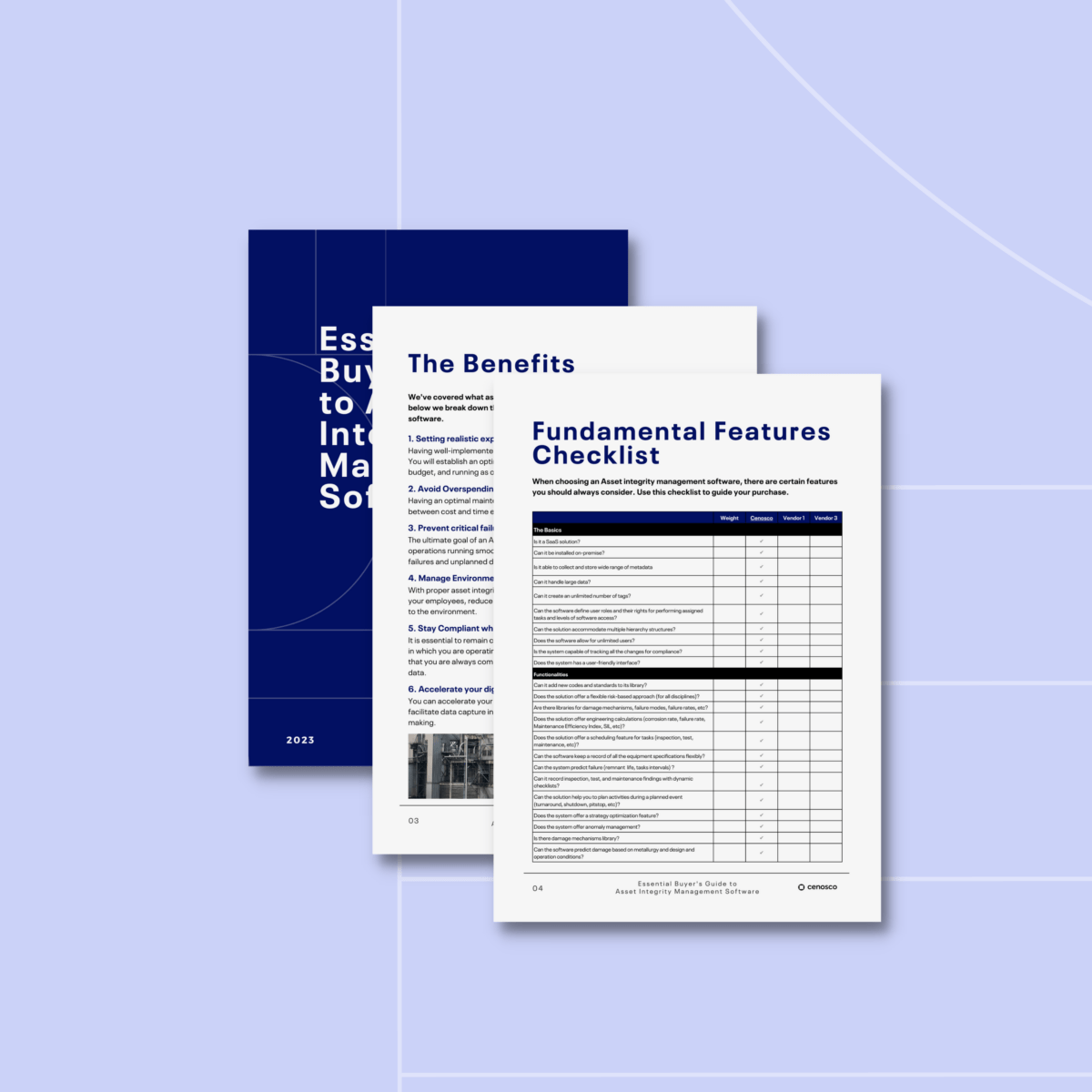

Essential Buyer’s Guide to

Asset Integrity Management Software

Not sure where to start? Download the ultimate buyer’s guide to set you on the right direction.

Free Buyer’s Guide

What’s Inside?

The Asset Integrity Management landscape is a broad and complex one, with various overlapping terms and functionalities. Because of this, it can be difficult to analyze what you really need in your software beyond the buzzwords. This guide aims to facilitate prospective buyers’ journeys.

This guide contains everything you need to get started with your buying journey, including an extensive “Fundamental Features” checklist for you to use to evaluate your needs against your vendor options.

✅ Manage environmental, health, and safety risks

✅ Prevent critical failures and reduce downtime

✅ Accelerate your digital maturity journey

Which industries benefit the most from Asset Performance Management software?

- Oil and Gas: APM software is critical in the oil and gas sector for monitoring drilling rigs, pipelines, refineries, and other equipment. It helps ensure the safe and efficient operation of facilities and reduces the risks associated with equipment failures.

- Chemicals and Pharmaceuticals: Industries producing chemicals and pharmaceuticals rely on APM software to manage the performance of reactors, mixing equipment, and other production assets. This helps maintain product quality, prevent contamination, and ensure regulatory compliance.

- Pulp and Paper: Paper mills and related industries use APM software to monitor and manage the performance of machinery involved in pulp processing, paper production, and packaging.

- Energy and Utilities: Power generation plants, including nuclear, fossil fuel, and renewable energy sources, use APM software to manage the performance of turbines, generators, transformers, and other equipment. Utilities also rely on APM to monitor and maintain water and wastewater treatment facilities.

- All Asset-Heavy industries

What are the benefits of implementing Asset Performance Management?

By collecting and analyzing data on equipment performance, temperature, and other indicators, the software can detect anomalies and patterns that indicate potential issues before they escalate into major failures.

Contact Us

Learn more about the leading

Asset Integrity Management Software