Integrity Management System

Unified asset

integrity software

Meet IMS, our asset management and maintenance software. Our cloud-based software to safeguard integrity, reliability, and instrumentation safety in asset-intensive industries.

Trusted by Industry Leaders

Benefits

- Optimize your inspection and maintenance costs

- Access exclusive libraries and methodologies

- Offline and Mobile functionalities

From reactive to predictive.

Upgrade your maintenance maturity from reactive to predictive. Find unified solutions for all your equipment types: Pressure, Civil, Electrical, Rotating and Pipelines. The IMS Suite has been designed to support users in making smart inspection and maintenance decisions to increase safety, maximize asset availability and optimize asset management costs. IMS was created in collaboration with world-renowned Oil & Gas leader, Shell, and puts over twenty years of experience at your finger tips. Our solutions are trusted worldwide by industry leading companies.

For asset-heavy industries

IMS PEI (Pressure Equipment Integrity)

IMS PEI is a Pressure Equipment Integrity cloud-based software. It helps prevent leaks and explosions by improving your asset availability through inspection planning. You don’t need to have an expensive inspection schedule to ensure the safety of your people and high asset availability. With IMS PEI, you will optimize your inspection schedules so that you can operate as safely and budget-friendly as possible.

Asset Managers will get the most benefit out of the solution, as it will help them achieve their goals for asset availability and optimal inspection costs. This will come together with an overview of the risk profile.

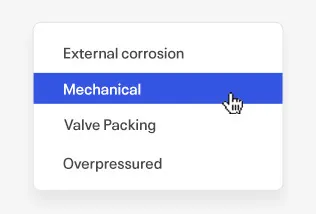

IMS RCM (Reliability Centered Maintenance)

IMS RCM is a Reliability Centered Maintenance cloud-based software. It helps prevent unplanned failure by improving asset availability through maintenance. You don’t need to have an expensive maintenance plan to ensure the safety of your people and high asset availability. With IMS RCM, you will optimize your maintenance tasks so that you can operate as safely and budget-friendly as possible.

Reliability Managers gain access to an exclusive library of reliability strategies. Follow a guided 7-step RCM2 analysis and create your perfect cost-effective maintenance strategy.

IMS PLSS (Pipeline and Subsea Systems)

IMS PLSS is a Pipeline and Subsea Integrity cloud-based software. It helps prevent leaks and explosions by improving your asset availability through inspection planning. You don’t need to have an expensive inspection schedule to ensure the safety of your people and high asset availability. With IMS PLSS, you will optimize your inspection schedules for internal and external corrosion.

Inspection Engineers can prevent corrosion on buried pipelines through Cathodic protection monitoring. Link your overview to the data historian and access advanced corrosion prediction calculations.

IMS SIS (Safety Instrumented Systems)

The SIS Lifecycle processes can be overwhelming, with many stages and disciplines involved. With our SIS Lifecycle software, you no longer need to feel overwhelmed by the complexities of SIS Lifecycle management! This comprehensive cloud-based tool will support the complete safety lifecycle management process as per IEC61508 & IEC61511.

Asset Managers will get the most benefit out of the solution, as it will help them achieve their goals of ensuring their site is Functional Safety Assessment (FSA) audit-ready at every phase of the safety lifecycle.

IMS FCM (Flange Connection Management)

IMS FCM is a Flange Management cloud-based software, which helps you manage flange integrity. It prevents leaks in flanges, which is the number one source of leaks in various asset-heavy industries. With IMS FCM, you can optimize your costs and maintenance plan, as well as ensure proper practices for tension and torque.

Field Technicians Thanks to the offline feature, conduct proof tests on the field with ease and upload the results. Enjoy full-fledged capabilities, such as online and offline functionality, configurable guided proof test protocols, and fully fleshed mobile capabilities.

Trusted worldwide

See IMS in action

Ready to see what our solutions can do for you? Get started quickly with a demo!