Benefits at a glance

- Predict and mitigate internal corrosion

- Minimize CAPEX costs for new projects

- Optimize OPEX costs for existing facilities

Corrosion Prediction

and Material Selection

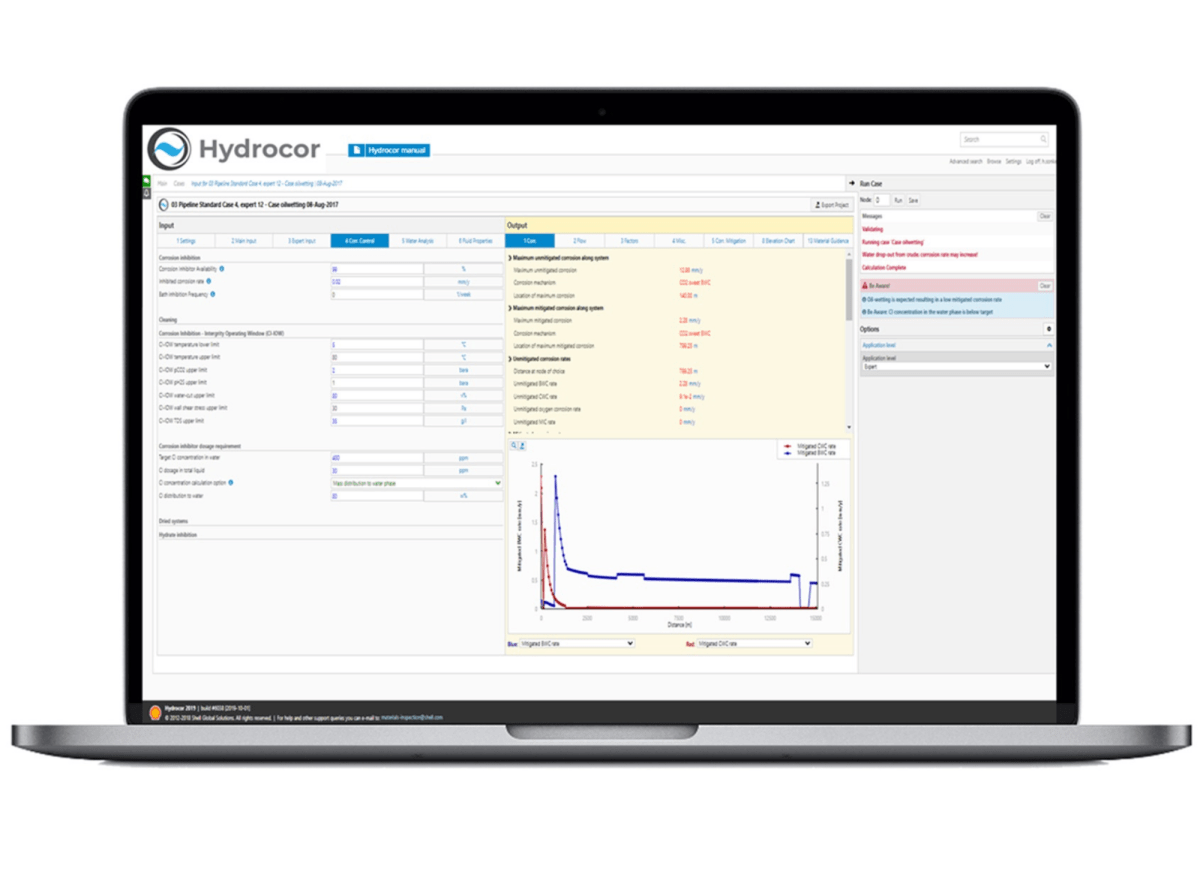

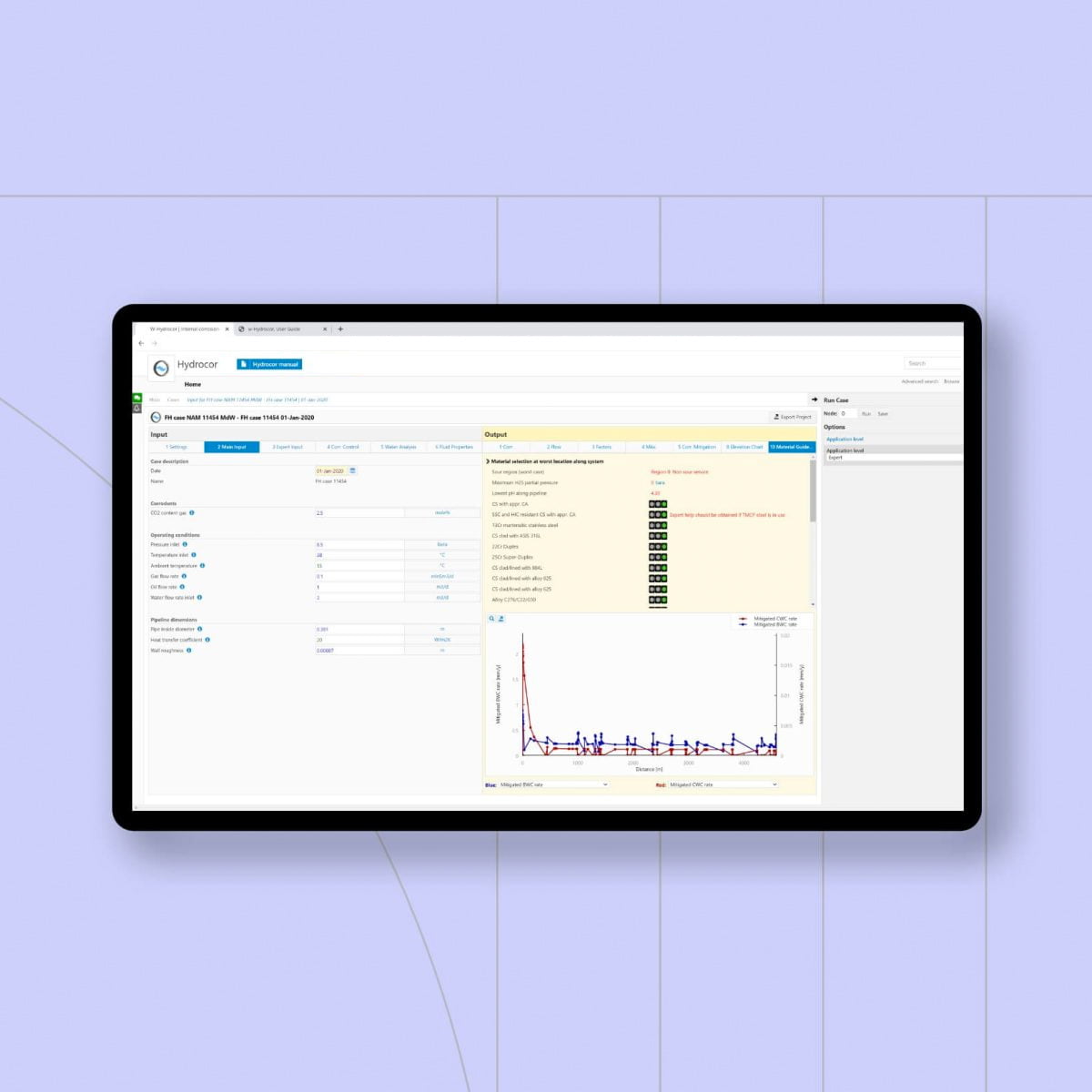

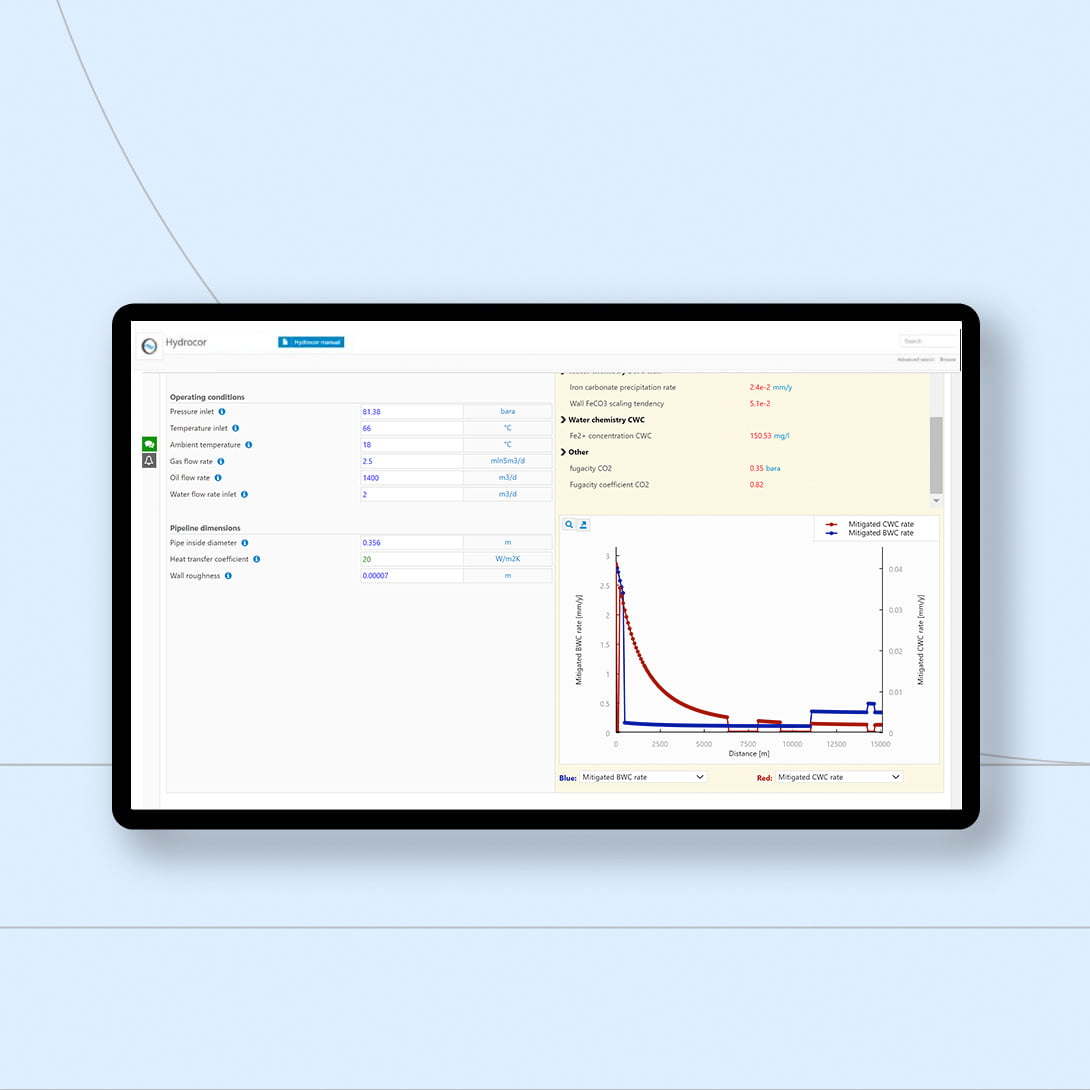

Hydrocor is a cloud-based internal corrosion calculation and prediction software solution. It helps prevent leaks and explosions by improving your asset availability. This is done firstly through the design stage, by helping you choose the right materials for your processes. Secondly, through proper corrosion prediction and maintenance planning. You don’t need to have an expensive maintenance schedule to ensure the safety of your people and high asset availability. With Hydrocor, you will optimize your maintenance schedules for internal corrosion through degradation rate prediction.

Schedule a callKey Features

Optimize your maintenance schedules for internal corrosion

Below we lay out some of the key features of Hydrocor. Explore the many ways in which our corrosion prediction software can help you gain control of your operations

Corrosion Prediction

Predict corrosion based on various degradation mechanisms: CO2, H2S, Organic Acids, O2 Corrosion, Microbial Corrosion

Request a demo

Smart Materials Selection

Calculate corrosion rate per material and overview options with a user-friendly traffic light system.

Schedule a call

Load scenarios and project life simulations

Create scenarios during the entire pipeline lifecycle, to mitigate corrosion

Request a demoStakeholder Overview

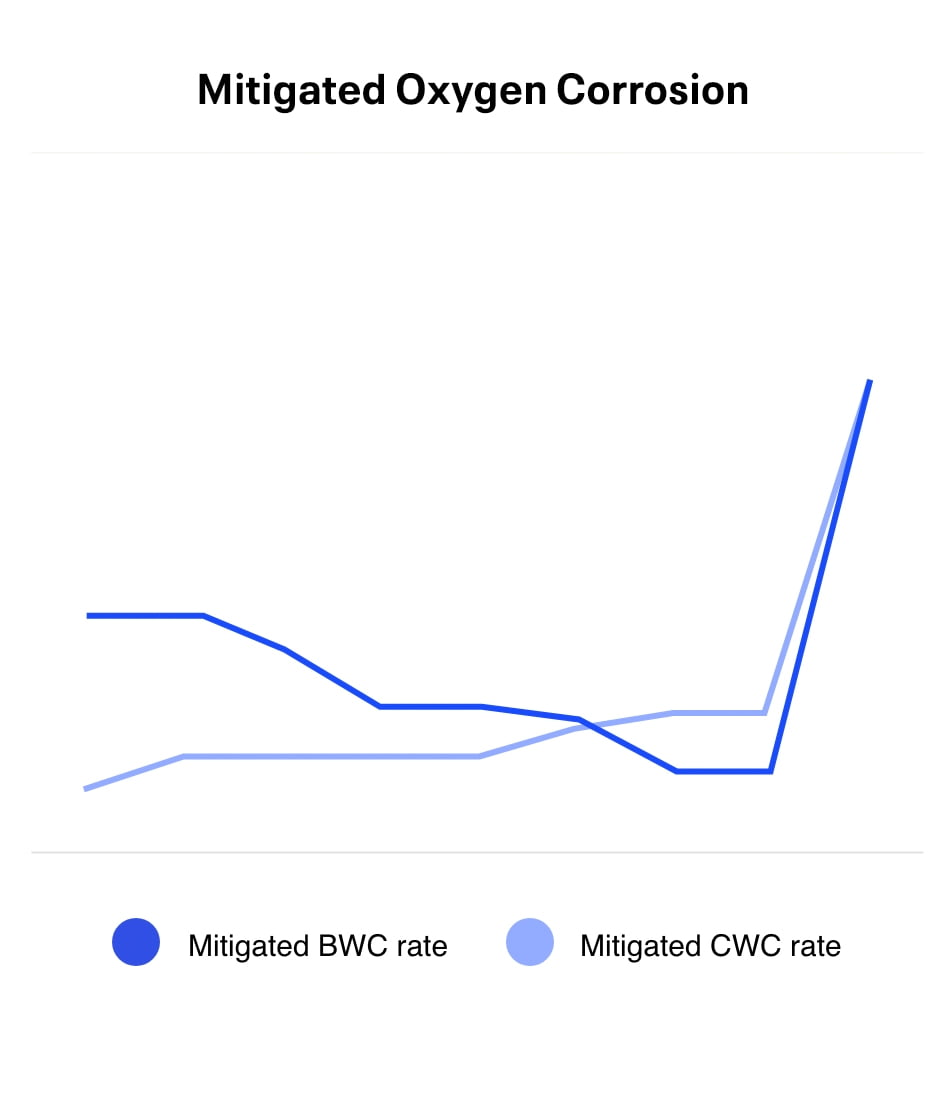

Graphical representation of correlations in analysis

View graphical representations of different correlations based on your data.

Schedule a call