Benefits

- Optimal inspection costs

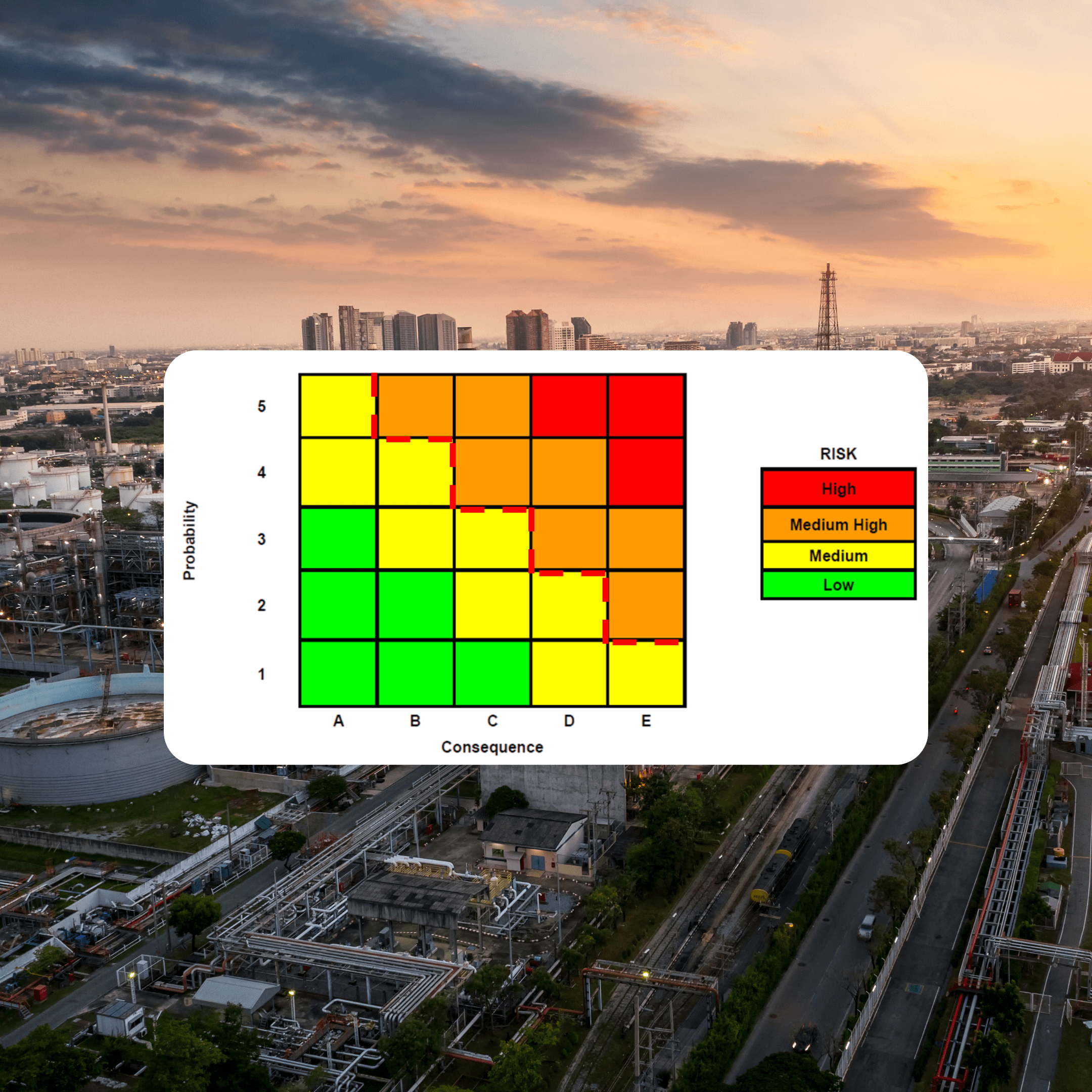

- Upgrade from time-based to risk-based inspection

- Proven methodology with flexible risk ranking

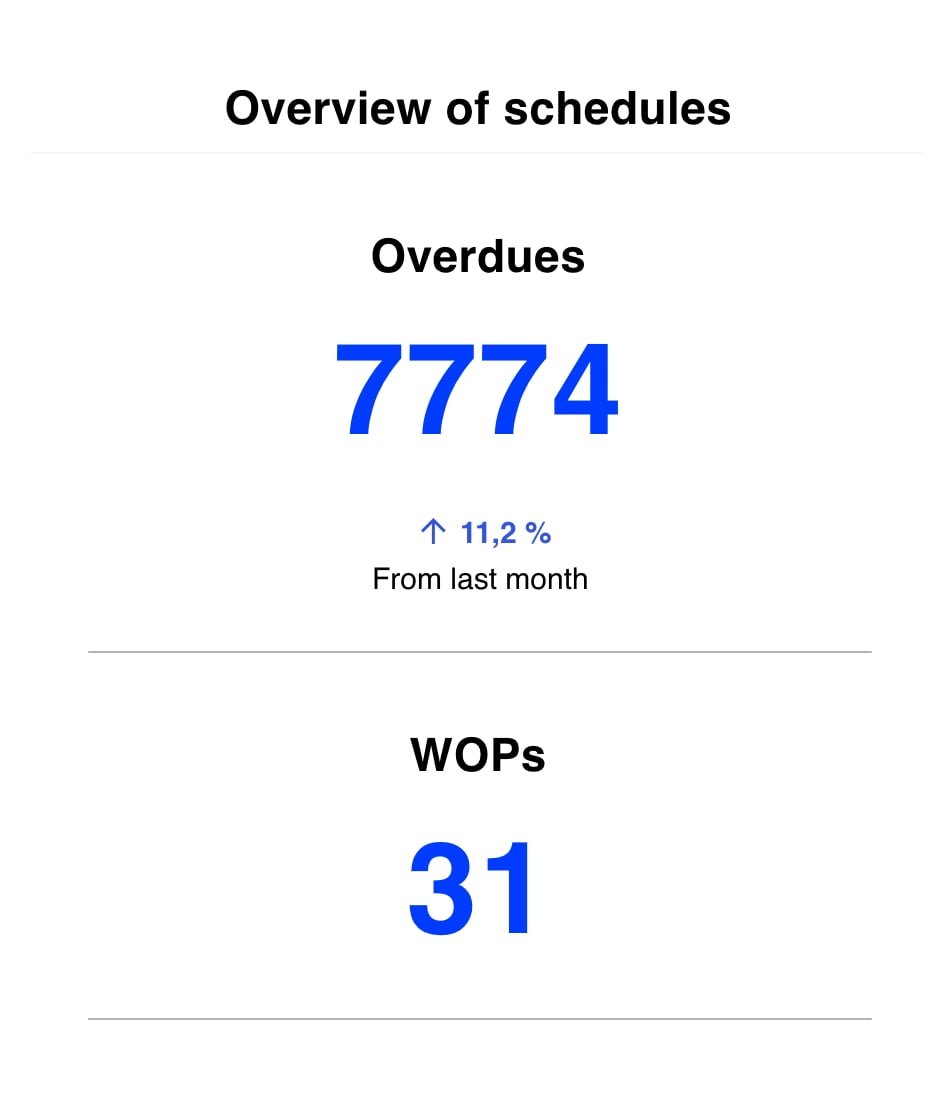

Never miss an inspection again

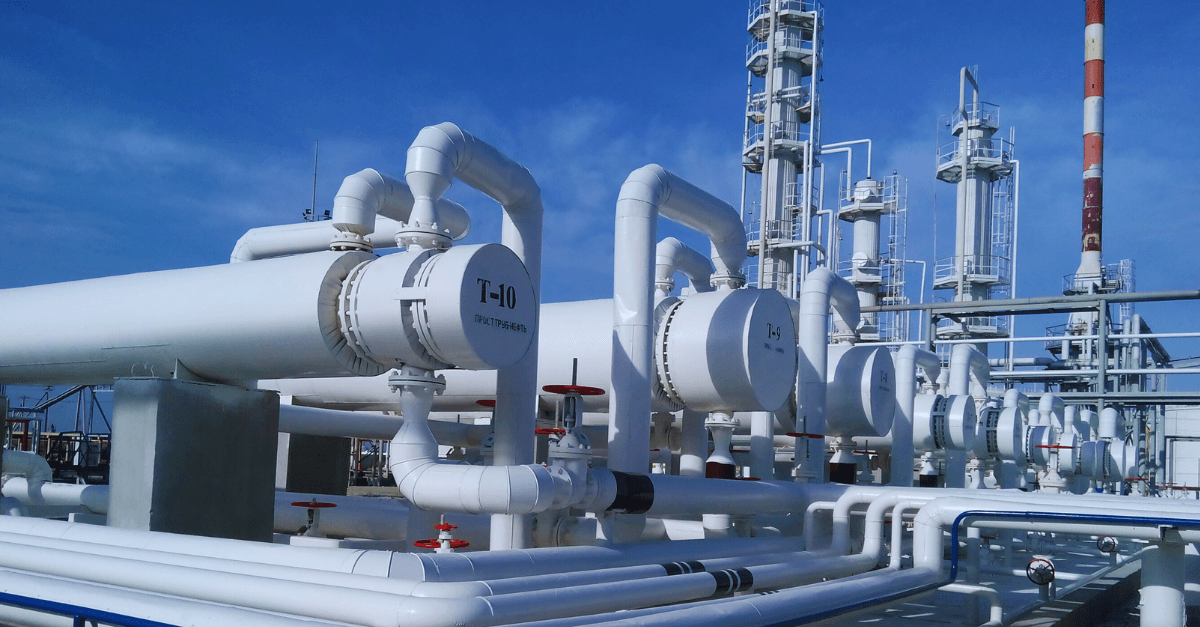

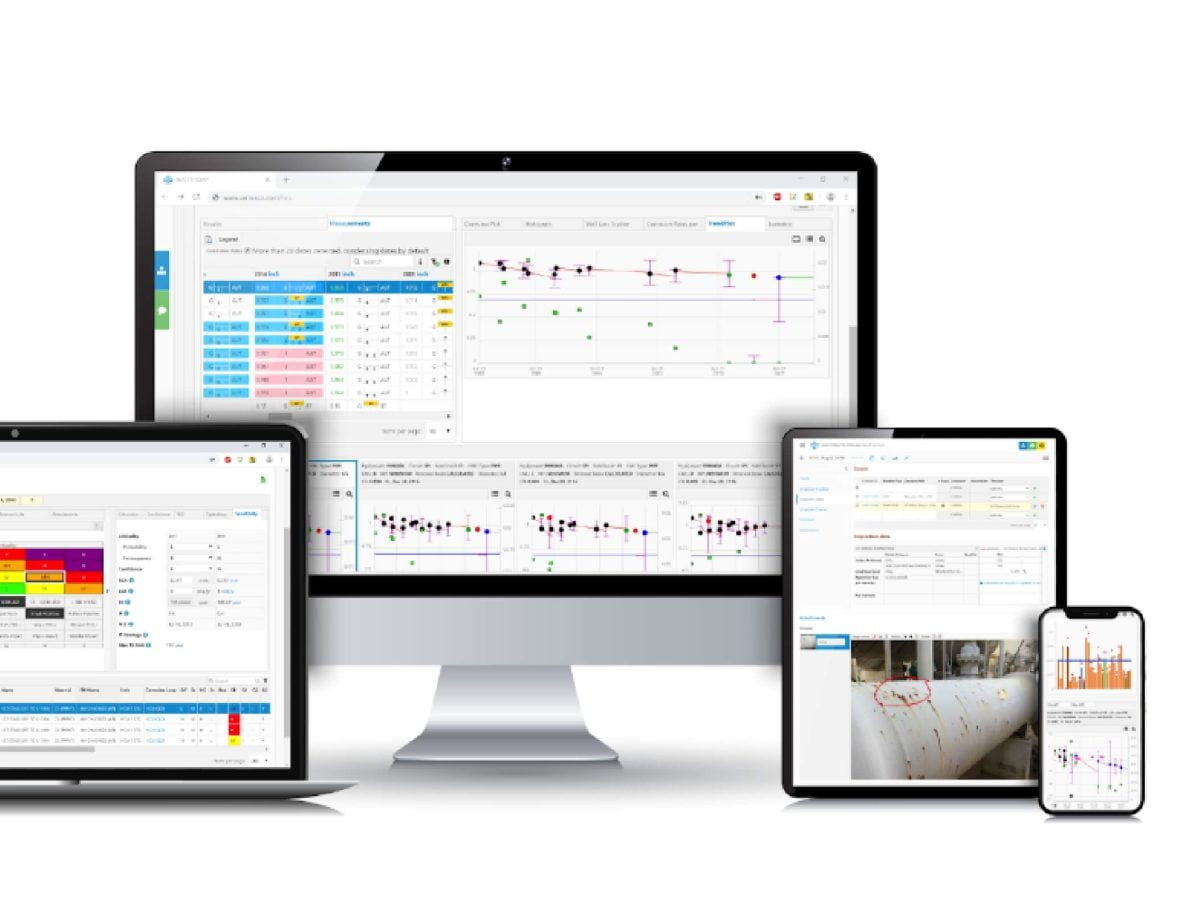

IMS PEI is a Pressure Equipment Integrity cloud-based software. It helps prevent leaks and explosions by improving your asset availability through inspection planning.

You don’t need to have an expensive inspection schedule to ensure the safety of your people and high asset availability. With IMS PEI, you will optimize your inspection schedules so that you can operate as safely and budget-friendly as possible.

RBI for pressure equipment

RBI Methodology

IMS supports qualitative, semi-quantitative and fully quantitative RBI methodologies in accordance to API 580 / 581. We deliver advanced RBI features, including but not limited to:

▪️Support API 580 / API 581 for pressure equipment

▪️Configurable generic failure frequencies

▪️Configurable Inspection effectiveness criteria’s

▪️Tracking implementation and execution of the RBI program

Let’s find the best-fit RBI methodology for your needs…

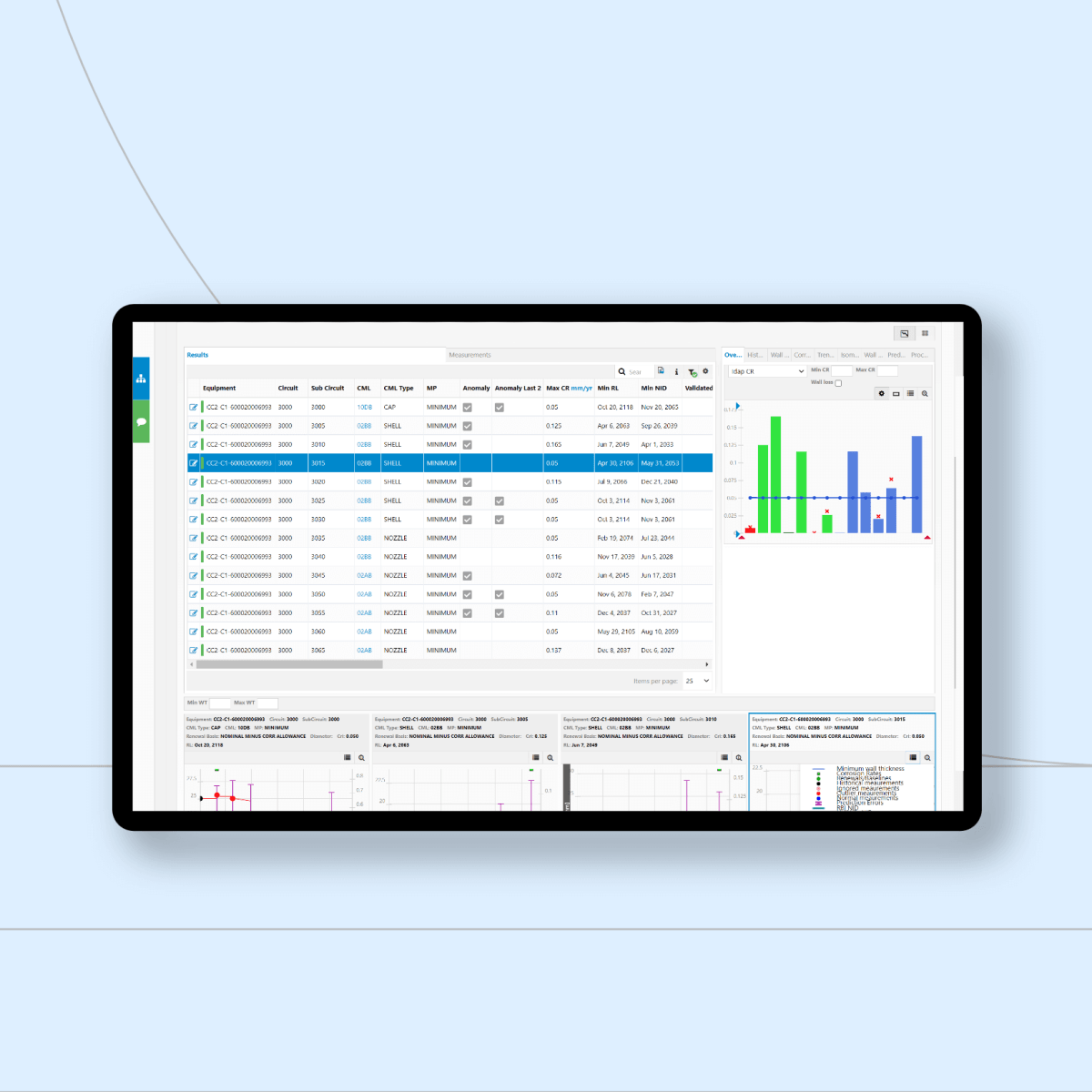

Advanced

corrosion predictions

Don’t let your data go to waste, rather use it to make data-driven decisions on when to carry out your next inspection.

Schedule a call

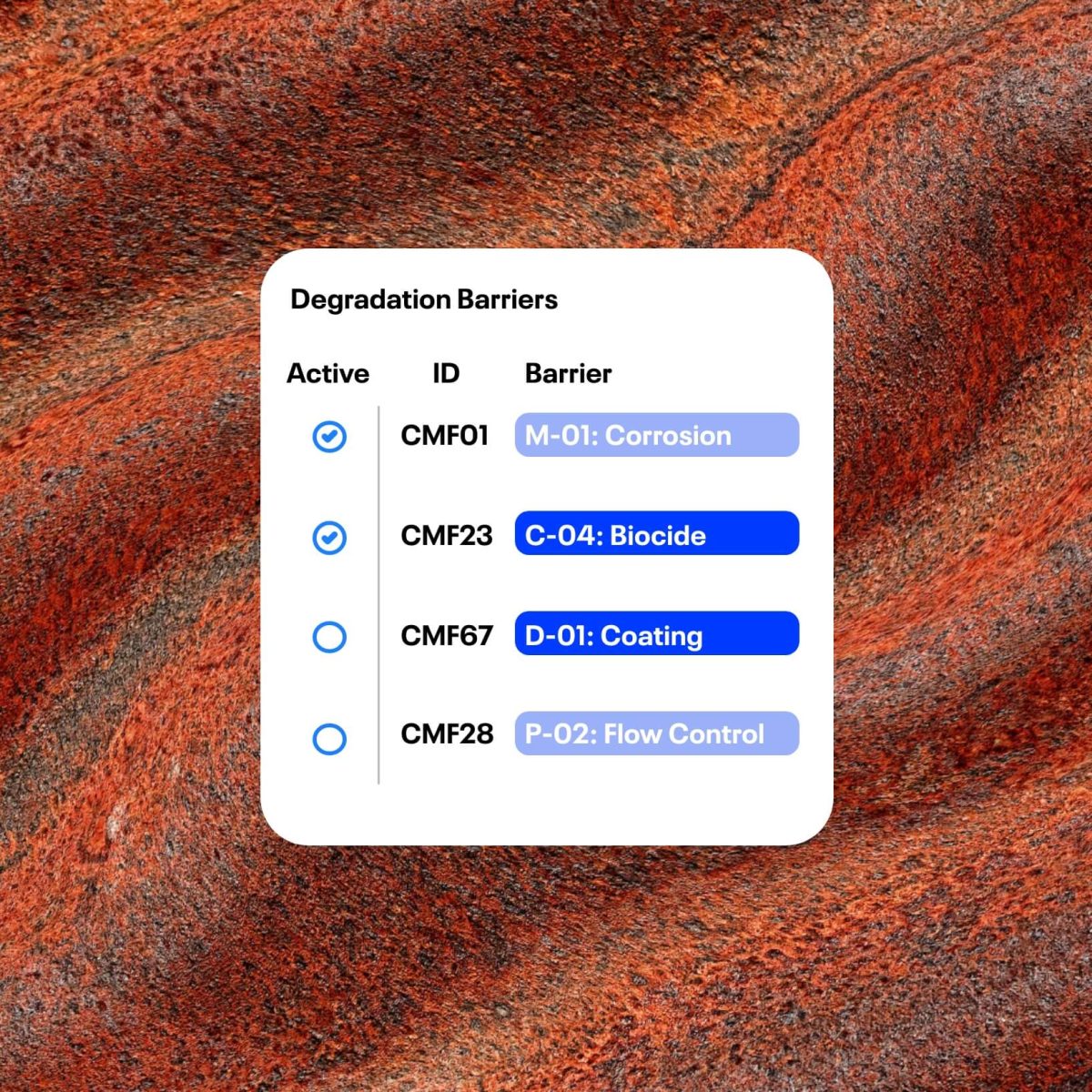

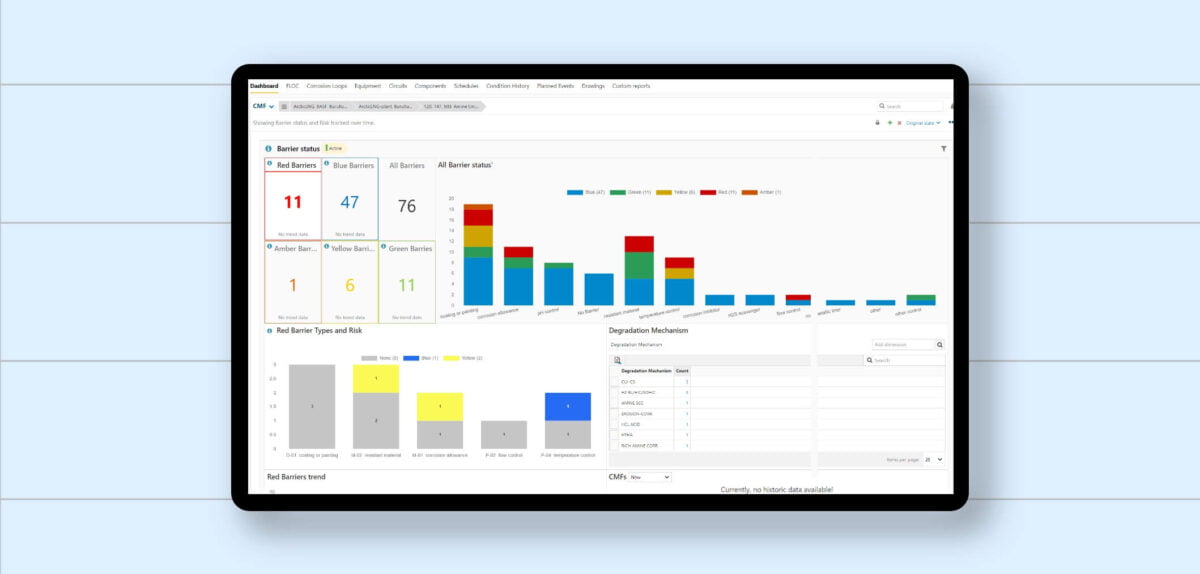

Corrosion Management Framework

Access a framework that will provide an overview of all degradation mechanisms, and status of your barriers This is automatically linked to your data historian.

Request a demo

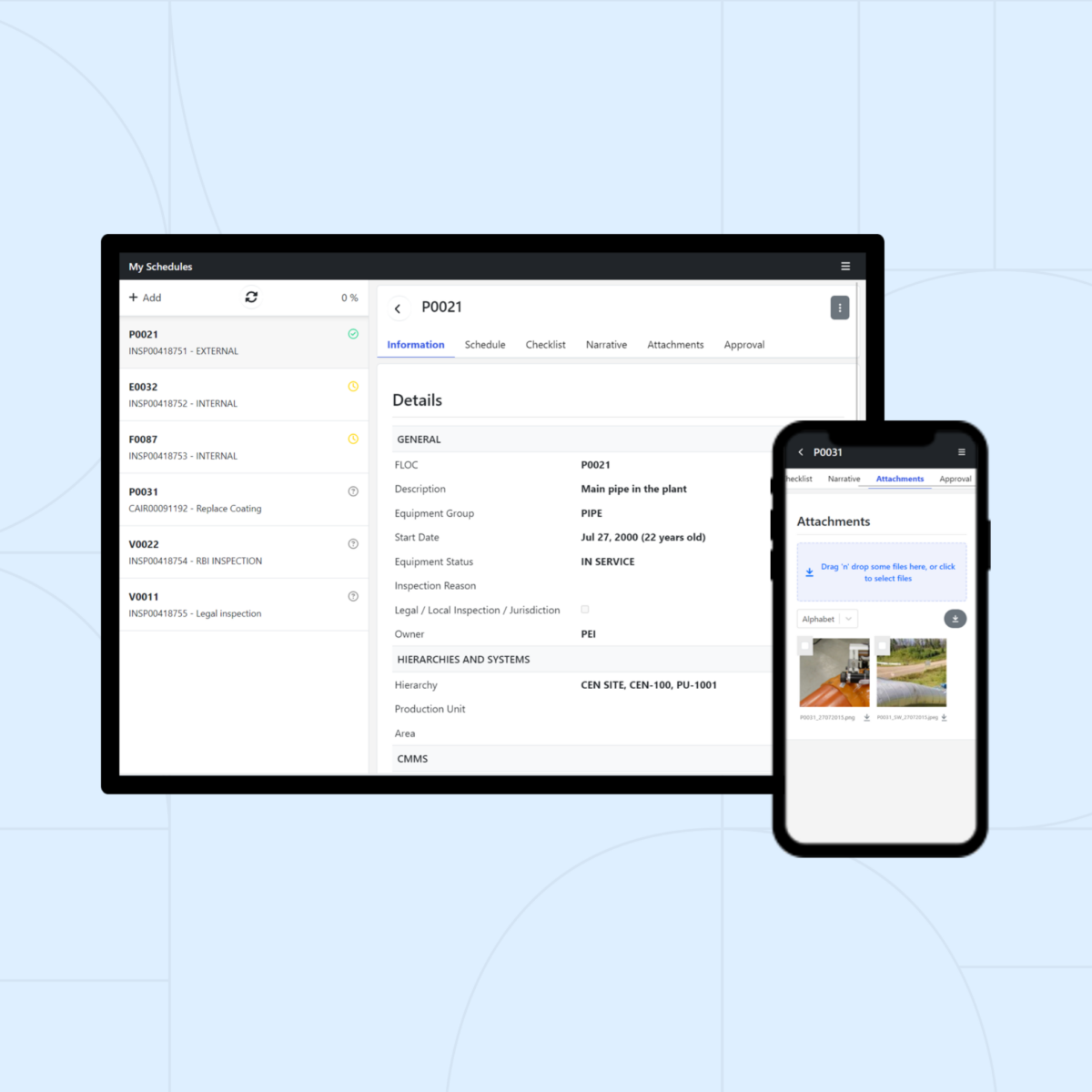

Inspection Data Management System

Access the next generation of inspection data management systems. Upgrade from time-based inspection to predictive risk-based inspection.

Schedule a call

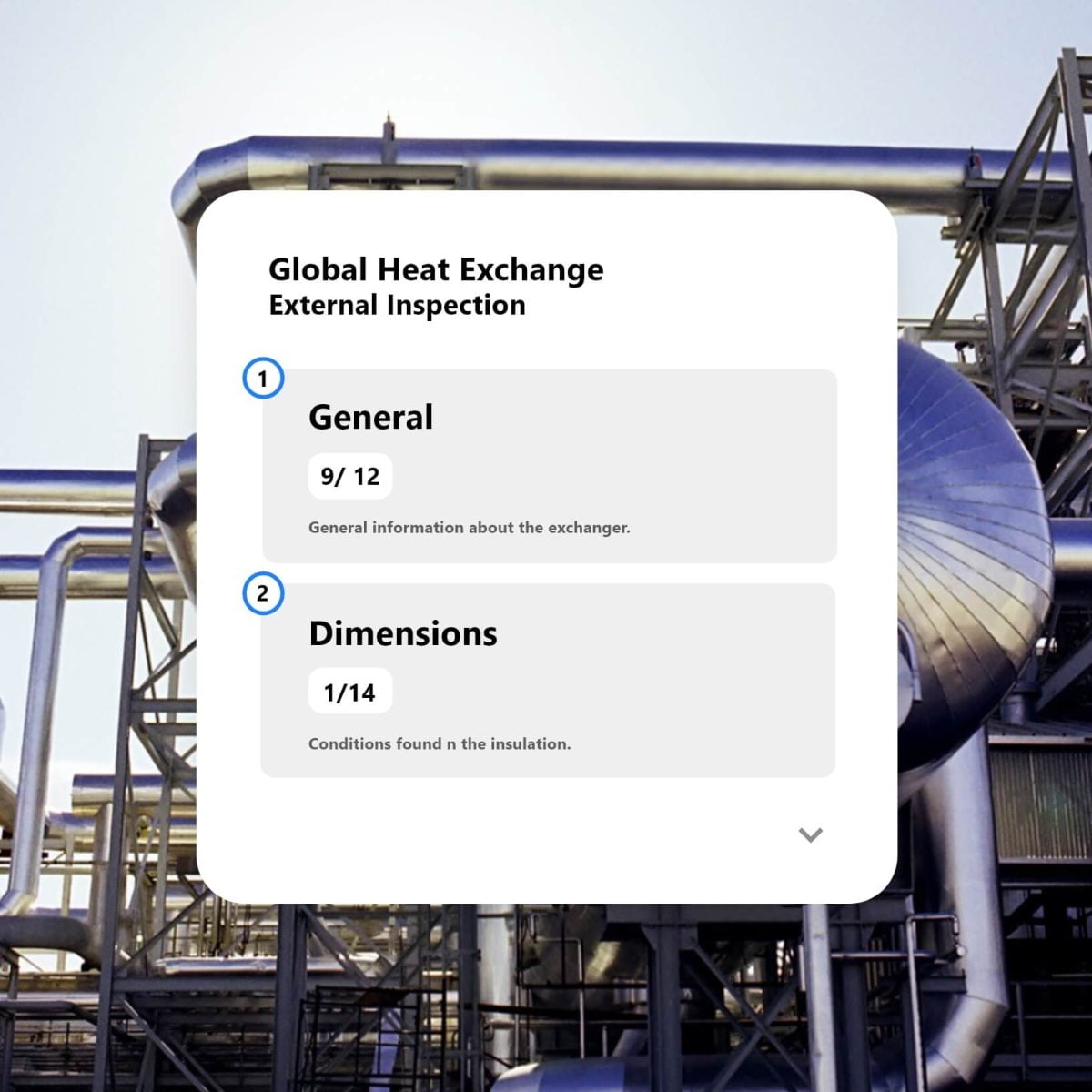

Dynamic

Forms

Create your own guided checklist, configured to your particular needs. You will get smart recommendations for your process based on your particular scenario.

Request a demoStakeholder Overview

Advanced features

IMS Suite Core Features

IMS PEI is part of the IMS Suite, a unified set of software solutions for all your equipment types and processes. Below is an overview of the core features that all solutions within the IMS Suite can benefit from.

Asset Hierarchy

Keep your asset register clean and organized.

Interface to ERP systems

Such as SAP, JDE, Maximo, and more.

Offline mobile functionality

Ease inspections when out in the field.

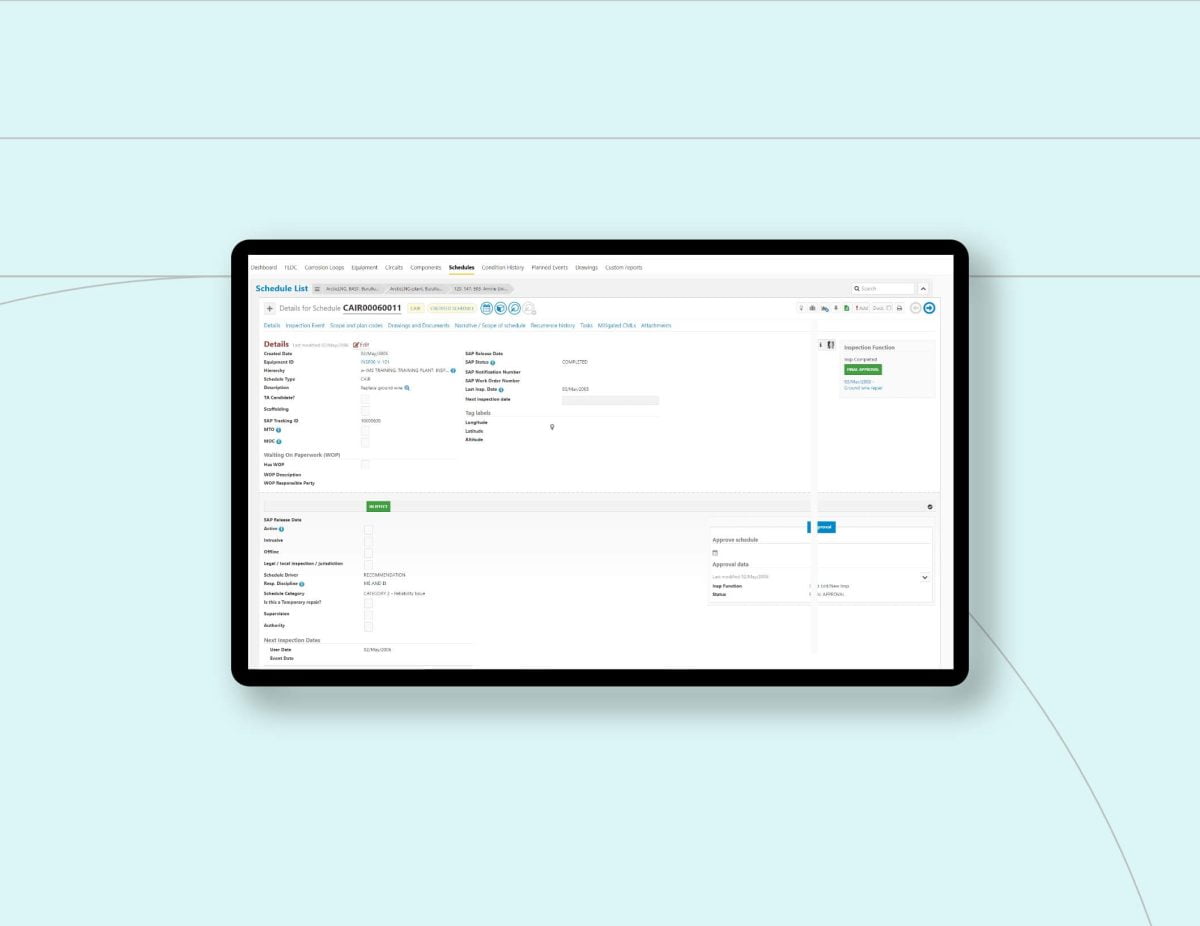

Scheduling

Transform all your analyses into a planned schedule or maintenance strategy.

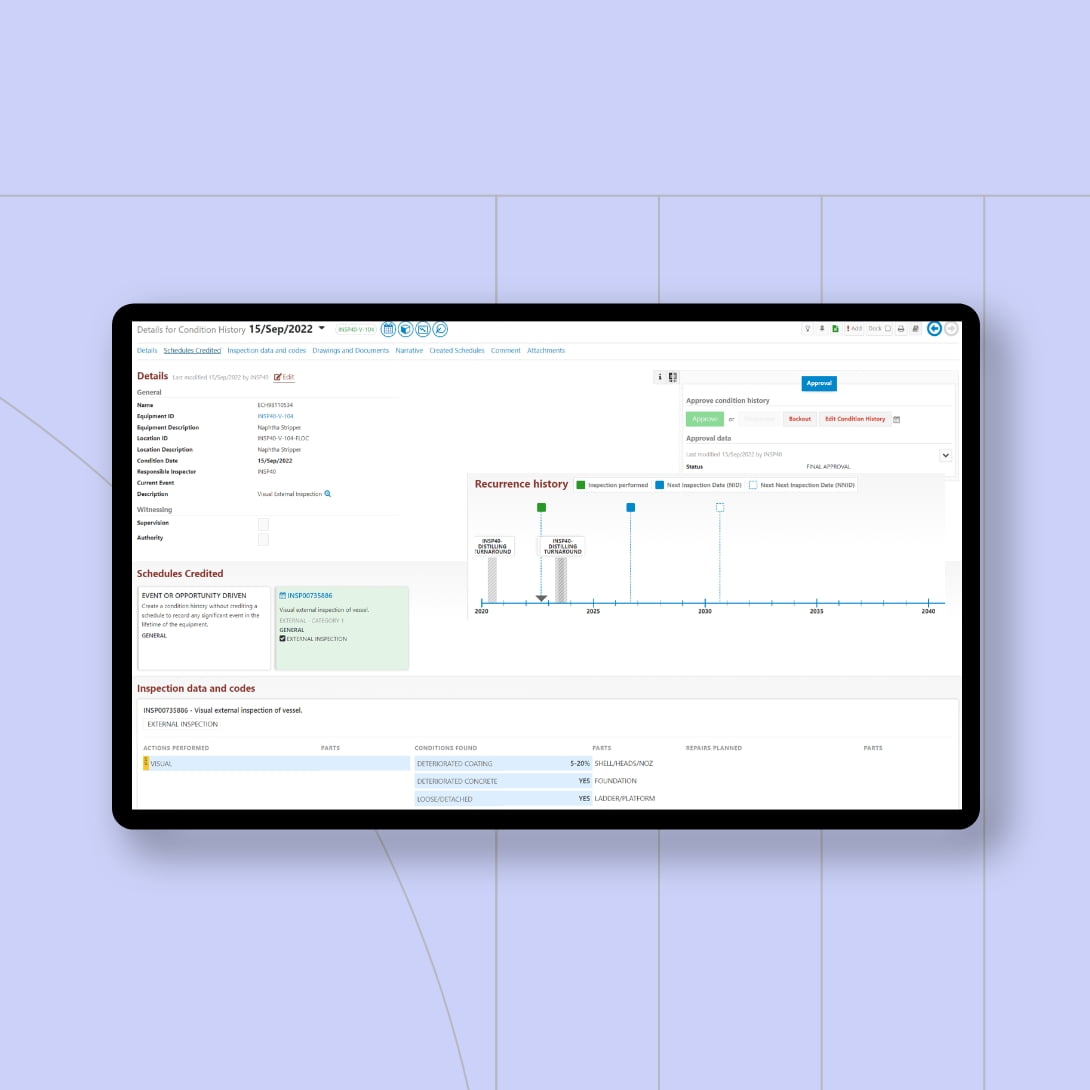

Condition History

Track all events in the lifetime of your equipment, from inspections to leaks to temporary repairs.

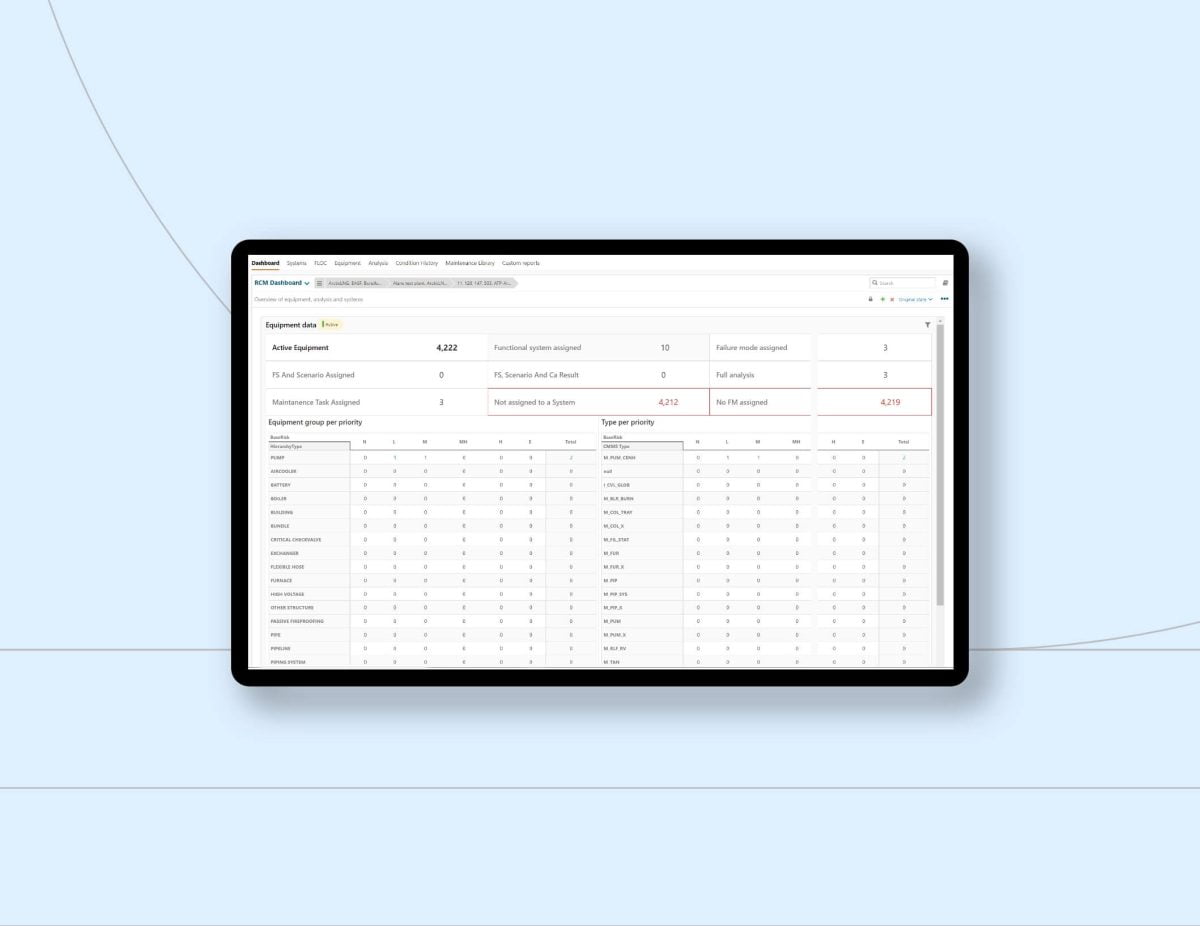

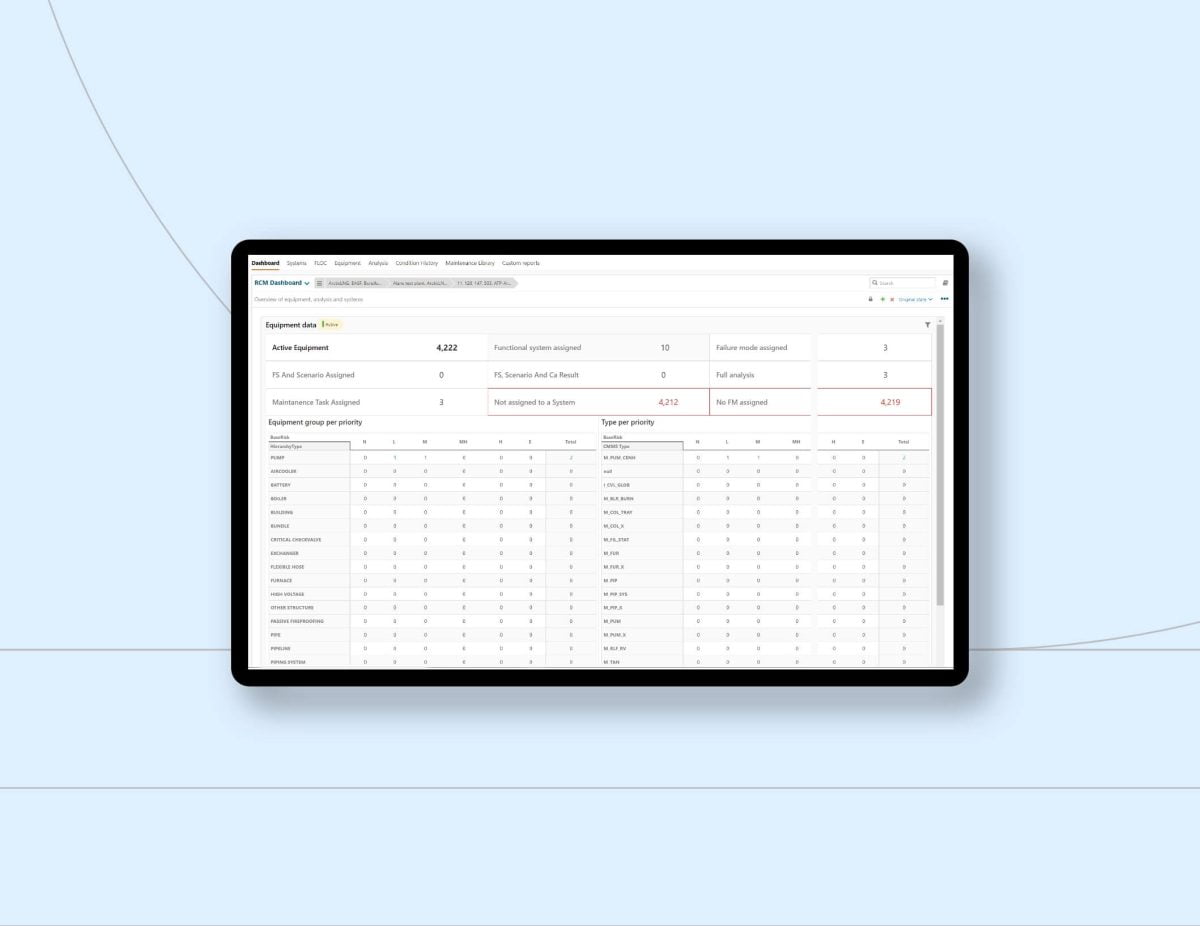

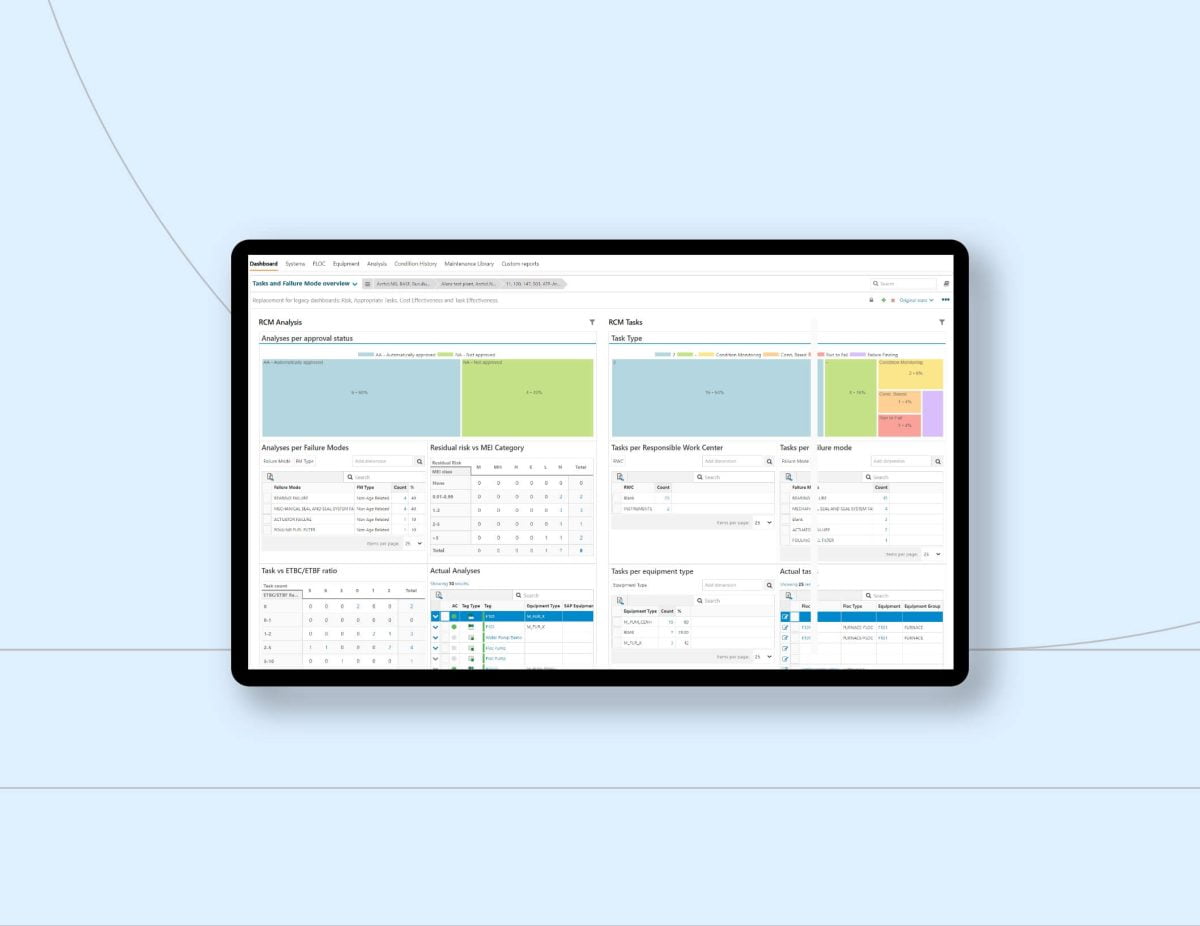

Configurable Dashboards

Visualize the most relevant data to you.

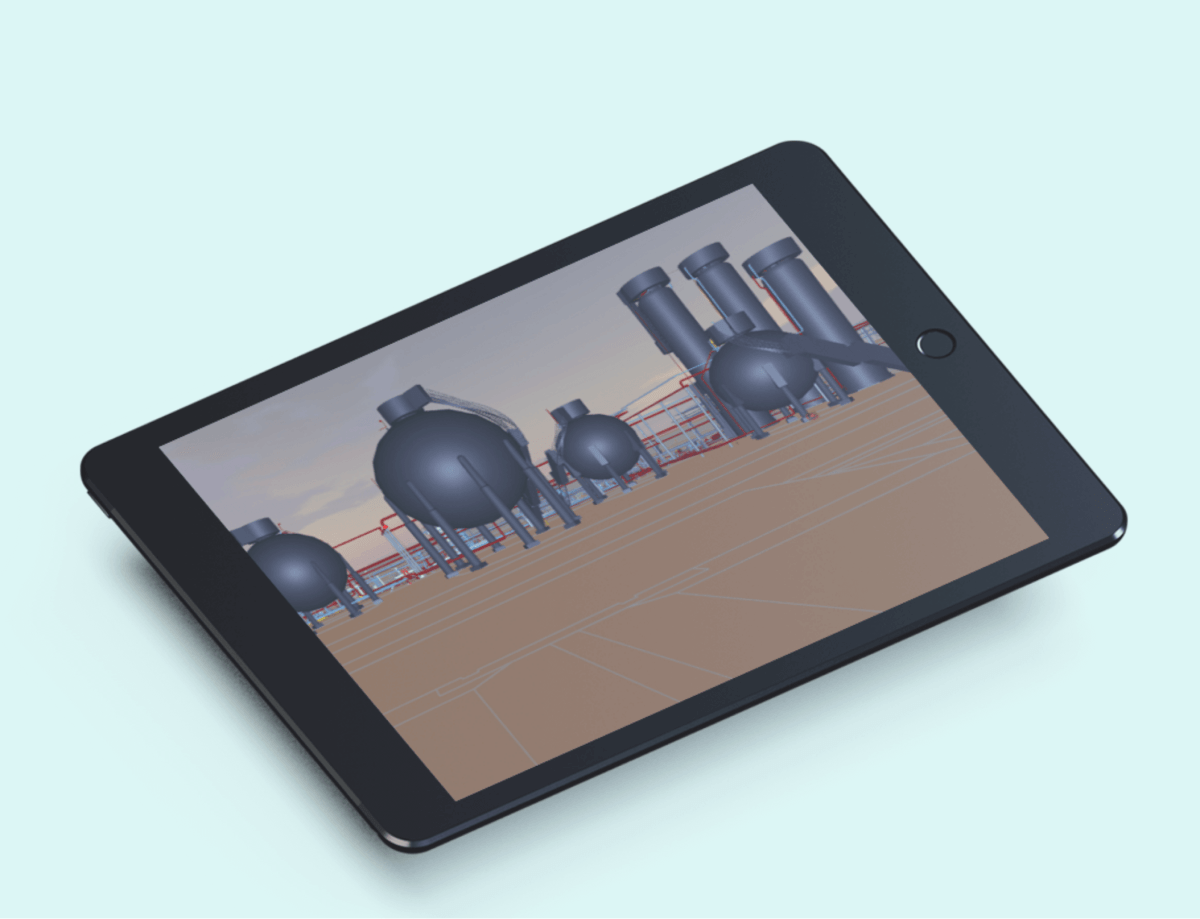

2D and 3D Capabilities

Enhance your inspection data by visualizing it into 2D drawings or 3D models.

Compliance

Meet compliant regulations through proper condition history.

Insights into bad actors

Use your data to stay ahead of the curve of bad actors and your equipment’s performance.

Tailor-Made Roles

Set up your user profiles based on different disciplines.

IMS4Field

Embrace the ease of digital checklists for all your field work.

Does IMS PEI comply with API 581, and what RBI capabilities does it offer?

Yes, IMS PEI supports API 581 compliance for pressure equipment and delivers a robust suite of Risk-Based Inspection (RBI) capabilities. These include, but are not limited to:

20x Damage Factor Calculations for various degradation mechanisms

Configurable Generic Failure Frequencies

Probability of Failure (PoF) and Consequence of Failure (CoF) assessments

Customizable Inspection Effectiveness Criteria

Configurable risk targets and inspection interval settings

Linking RBI outputs directly to inspection schedules and plans

Degradation management with API 571 mechanisms tied to API 581 damage factors, allowing updates to barriers and connection to Integrity Operating Windows (IOWs)

With these features, IMS PEI enables organizations to confidently manage asset integrity and optimize inspection strategies in alignment with API 580 and 581 standards.

What are the platform’s import capabilities?

IMS platform offers robust import capabilities through an Import Wizard, allowing bulk data imports using predefined Excel templates.

Users can select from different import types, such as Class Import or MESC Import, and follow a guided process to map, validate, and finalize their data import efficiently.

I have no past experience working with the RBI Methodology, how quickly can I get started using IMS PEI?

The Cenosco Academy is our e-learning platform that covers a wide range of both hands-on tool training and methodology deep dives.

Our platform allows users to learn new techniques or polish their skills in a trackable, self-paced environment.

My company has very strict requirements in terms of security, is it possible to host this application on our own servers?

We provide our customers with a variety of hosting options. Including Shared, Dedicated and On-Premise. We advise against On-Premise hosting, as offer the latest and greatest in terms of security.

Read more about this topic in our blog post: Integrity Management Software: SaaS or Perpetual License

I’ve already done a lot of work in a different system or offline, can you assist me in getting this data inside the IMS System?

Of course! We have both Data Migration and Integration services at your disposal.