A Safety Requirements Specification (SRS) is a critical document in functional safety, providing a clear and structured definition of what each Safety Instrumented Function (SIF) must do to mitigate risks. It outlines the functional, integrity, and performance requirements needed to meet the target Safety Integrity Level (SIL) as defined in international standards such as IEC 61508 and IEC 61511.

The SRS is essential because it ensures alignment between hazard identification, risk assessments, and the technical design of safety systems. It gives engineers, designers, and operators a common reference point for implementing and maintaining safety functions throughout the lifecycle.

Without a well-developed and maintained SRS, even carefully engineered safety systems can fail audits, fall out of compliance, or perform inadequately during critical events.

This article explains the role of the SRS in functional safety, why it is essential for compliance, and how to develop one effectively.

Why Is SRS Important for Functional Safety?

The Safety Requirements Specification is more than just a formal deliverable; it is the backbone of traceability and compliance in the functional safety lifecycle. It ensures that the intent captured during hazard studies such as HAZOP and risk assessments like LOPA is carried through to the design and validation of Safety Instrumented Functions (SIFs).

When safety functions are not fully specified, even well-designed systems can fail at critical moments. The BP Texas City refinery explosion in 2005 is a stark example, where unclear requirements for abnormal startup conditions played a role in the disaster.

SRS Failures and the BP Texas City Explosion: What Went Wrong

At Texas City, a raffinate splitter tower was overfilled during startup, sending excess hydrocarbons into a blowdown drum that vented to the atmosphere. A vapor cloud formed and ignited, causing an explosion that killed 15 people and injured more than 170.

Investigators found that key safety functions were missing or poorly defined. Critical high-level alarms were either absent or failed to operate, and there were no automatic interlocks to stop feed into the tower when levels became unsafe. The lack of clearly specified functional and integrity requirements meant that safeguards were not designed to handle abnormal conditions.

A well-developed SRS could have addressed these gaps by defining:

- High-level detection and automatic feed isolation requirements.

- Integrity levels and testing intervals to ensure system reliability.

- Operational constraints and responses for startup conditions.

This level of specification would have provided a blueprint for implementing effective Safety Instrumented Functions (SIFs) and verifying their performance, reducing the likelihood of escalation.

Why a Bad SRS Could Be Your Most Expensive Mistake

The Texas City disaster is an extreme example, but even smaller gaps in an SRS can carry significant consequences. A poorly defined or outdated Safety Requirements Specification can result in:

- Design flaws that require costly rework or retrofits later in the project. Correcting safety system design errors during commissioning can add 10–15% to project costs, potentially amounting to millions on large-scale facilities.

- Operational downtime if safety systems don’t perform as intended during critical events. Unplanned shutdowns in high-hazard industries can cost between $100,000 and $1 million per day, depending on the scale of operations.

- Regulatory penalties and legal exposure if an audit reveals gaps in compliance with IEC 61508 or IEC 61511. Fines for safety non-compliance can range from $50,000 to over $1 million per incident, not including litigation costs.

- Reputational damage when clients and stakeholders lose confidence in your safety practices. The long-term impact on contract awards and insurance premiums can far exceed immediate financial losses.

In many cases, these costs far outweigh the investment needed to get the SRS right from the outset. Organizations that prioritize clarity, traceability, and maintainability in their SRSs reduce the risk of these cascading failures.

Tools for SRS Management and Verification

Managing a Safety Requirements Specification manually using spreadsheets or static documents often creates challenges. Version control becomes difficult as multiple stakeholders contribute, traceability between risk assessments and safety functions is lost, and maintaining compliance with IEC 61508 or IEC 61511 standards requires significant effort.

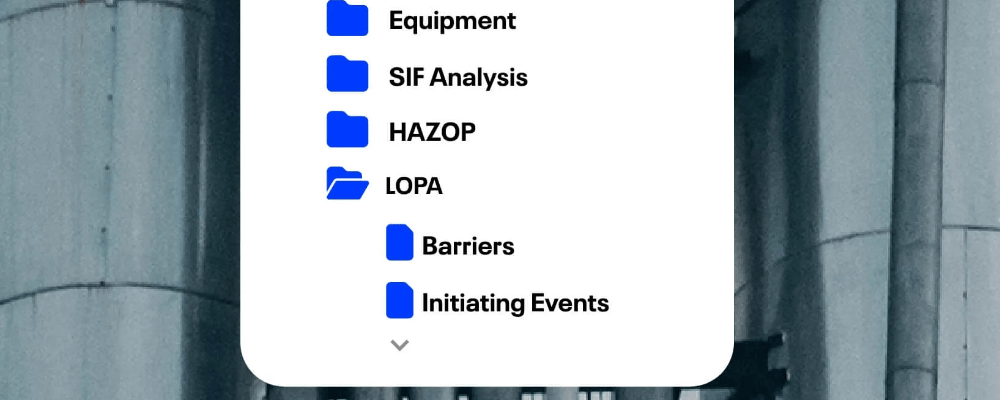

Modern software solutions address these issues by centralizing SRS management. Tools such as IMS SIS are designed to:

- Provide version control to track changes and maintain an audit trail.

- Ensure traceability from hazard analysis (HAZOP, LOPA) through to Safety Instrumented Function (SIF) design and SIL verification.

- Generate custom reports and dashboards to support compliance and decision-making.

By digitalizing SRS workflows, teams can reduce the risk of errors, improve collaboration across disciplines, and maintain an evergreen view of their safety lifecycle.

Best Practices for SRS in Functional Safety

Many SRS documents fall short because they are treated as one-off deliverables rather than evolving tools. To avoid gaps that can compromise safety and compliance, it is important to adopt practices that keep your SRS current and connected to the wider safety lifecycle.

1. Involve Cross-Functional Teams Early

Developing an SRS requires input from process engineers, functional safety specialists, operators, and maintenance personnel. Engaging these stakeholders early ensures the specification captures real-world operating conditions and practical constraints.

2. Keep the SRS “Live”

An SRS should not remain static after initial approval. As processes evolve and modifications are made, update the SRS to a new revision to reflect these changes and store the old revision for traceability purposes. Integrating the SRS into Management of Change (MOC) workflows helps maintain its relevance over time.

3. Link SRS to SIL Verification

Ensure that each Safety Instrumented Function (SIF) defined in the SRS is directly tied to SIL verification activities. This alignment provides traceability from risk assessment through to design, implementation, and testing.

4. Avoid Common Pitfalls

Be aware of issues that can undermine the effectiveness of an SRS, such as:

- Ambiguous functional requirements that leave room for interpretation. For example: “Start-up override present” instead of “During start-up of pump P-123, xxFZAyy-LL is overridden for 5 seconds in order for flow to exceed the LL trip setting. If flow does not exceed the LL trip setting after 5 seconds, the pump will be tripped, and P-123 start up procedure will have to be re-initiated again”

- Poor traceability between hazard analysis, SRS content, and implemented safety systems.

- Overlooking environmental or abnormal operating conditions that affect SIF performance.

By following these practices, organizations can ensure their SRS is a reliable foundation for functional safety and a strong defense against compliance failures.

Building a Reliable SRS for Functional Safety

In functional safety, the Safety Requirements Specification (SRS) doesn’t always get the attention it deserves. Yet it’s one of the few tools that connects risk analysis to the real-world performance of safety systems. It is the principal document against which the SIS is designed and commissioned.

As projects grow more complex and the demands of IEC 61508 and IEC 61511 become more rigorous, the way we manage SRS needs to evolve too. Relying on static documents and disconnected processes is no longer enough to ensure consistency, traceability, or compliance.

Simplify SRS and SIL Compliance with the Right Software

If you’re about to start developing an SRS, you’re at the perfect point to make one of the most important decisions of the entire safety lifecycle: choosing the right tool to support your work. The software you select at this stage will shape how effectively your team can collaborate, track changes, and maintain compliance long after the initial specification is complete.

That’s why global leaders in functional safety have turned to IMS SIS. It gives teams a structured way to develop, manage, and verify SRSs while keeping the entire safety lifecycle connected. With IMS SIS, you can avoid the pitfalls of manual processes and build a stronger foundation for safe, compliant operations.

Pieter Poldervaart Sr. Domain Expert Safety Instrumented Systems

Pieter Poldervaart is a functional safety expert with over a decade of experience in the field. Before joining Cenosco in 2021, he worked at Shell P&T, where he served as a LOPA chair and SIF Lifecycle Consultant, leading projects and training programs. At Cenosco, Pieter is the IMS SIS/SIFpro domain expert and tool trainer, helping engineers improve safety and reliability in industrial systems.

Learn more about IMS SIS

If you want to join other industry leaders using IMS SIS for their full SIS Lifecycle processes, fill out the form below to get started with a demo.