The primary focus of the IMS Release 2023.3 release centered on eliminating obstacles and streamlining processes to enhance collaboration, simplicity, and user-friendliness. Check out the highlighted new features below.

IMS Platform Improvements

Our major win for this release is definitely the standardization of schedules and condition histories across all disciplines. Additionally, the enhanced action items are something not to be missed. However, there are plenty more platform-related improvements listed in our release notes for you to explore!

Standardized Schedules and Condition Histories and Access Across Discipline

Schedules and condition histories are now seamlessly aligned across the different disciplines in IMS. By implementing standardized schedules and condition histories throughout IMS, we have brought RCM and SIS users to the same level as PEI and PLSS inspectors, providing a unified, comprehensive perspective of all maintenance and inspection tasks.

One fantastic benefit is that this standardization lets you see schedules and condition histories across ALL disciplines, fostering transparency and collaboration among teams. Default views will present relevant schedules and condition histories based on your discipline. You can then utilize filters to easily check out schedules and condition histories from other disciplines! This upgrade will help teams work together better and plan things more efficiently.

For more information on schedules and condition histories across discipline see: The IMS Handbook.

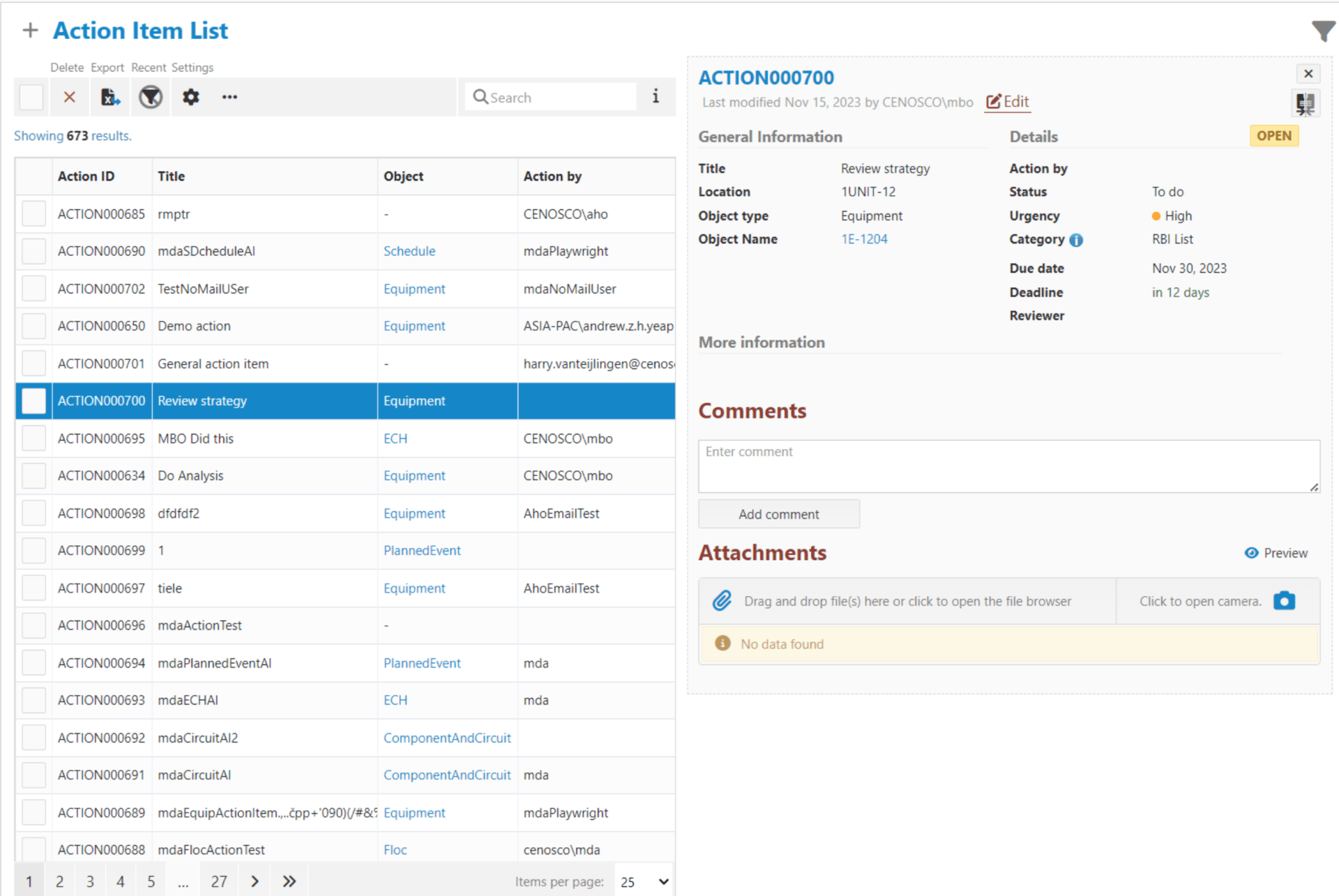

Revamped and Improved Action Items

Wave goodbye to those sticky notes! Now you can use Action Items to keep tabs on any IMS-related tasks or actions. The enhancements include the ability to assign the task to an assignee (action by) and a reviewer, send emails to assigned users, define status and category, comment on action items, and attach files. You can easily review all action items via an accessible list and track each action with unique identifiers. Moreover, you can create actions specific to certain objects (like equipment).

This improvement aims to boost accountability and efficiency through roles, notifications, and adaptable workflows. The user-friendly interface, actions linked to objects, and performance metrics significantly enhance task management within IMS.

For more information on Action Items see: The Ims Handbook.

User Engagement and Onboarding

Your feedback means a lot to us as we build IMS for you – our amazing users. We want to ensure that you are having a great experience, which is why we have added a feature for you to rate your satisfaction within the application (up to twice a year) and share your thoughts via comments. Your feedback goes directly to our customer experience team, dedicated to maximizing user satisfaction. And don’t worry; if you prefer, you can dismiss or cancel the survey at any time.

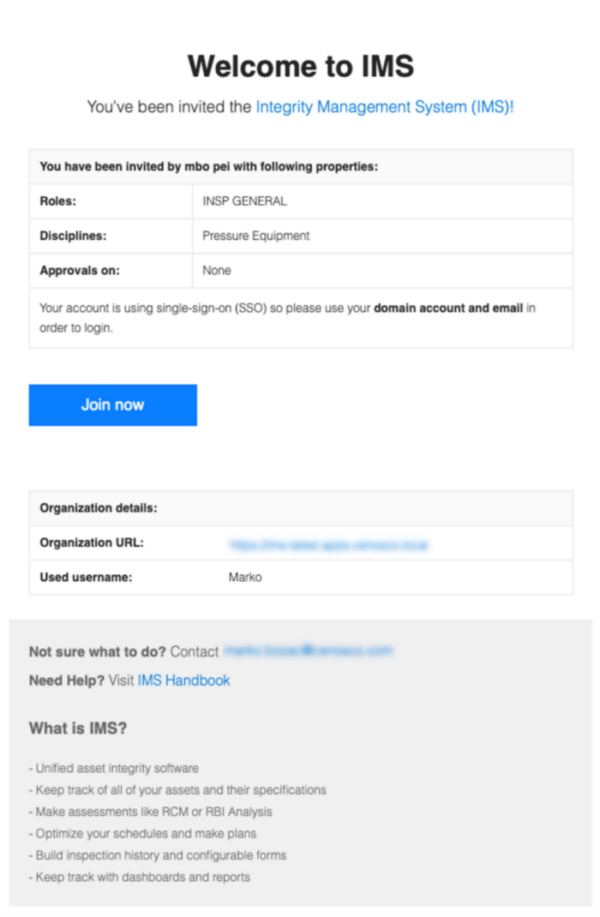

We have also rolled out a feature to make life simpler for new users: IMS now automatically sends welcome emails to new users. These emails contain useful info such as login details, whether single-sign-on (SSO) is active, their roles, disciplines, approvals, a quick intro to IMS, and where to find help – in the Handbook!

For information on the other IMS Platform improvements, see: IMS Platform (General) Release 2023.3.

IMS PEI Improvements

For PEI it is important to highlight the retirement of legacy inspection codes. In addition, this release concentrated on enhancing Risk-Based Inspections (RBI) and improving corrosion circuits.

Inspection Codes Replaced with Dynamic Forms

Even though Dynamic Forms have been around for a while, many of you were still stuck with the old inspection codes. Now, it’s finally time to bid farewell to those old codes and welcome the Dynamic Form checklists! While existing condition histories will still show the old codes, any new condition histories will now benefit from the upgraded and more user-friendly advanced Dynamic Forms checklists. Don’t worry – we have transferred your old codes into these new Dynamic Forms, ensuring familiar guidance during inspections but with an improved experience!

For more information on the transferred inspection codes, see: The IMS Handbook.

Wind Load Calculations Available on Tank Equipment

In the 2023 R2 release, we enhanced the management of tank degradation. Expanding on that progress, in this latest release, we have repositioned Load Case calculations to the equipment level. As a result, Courses can now be created as independent Shell components under tank equipment. Then, when conducting your wind load calculations, you can directly work on the equipment level and easily select one of these Shell components as the Governing Course, streamlining the wind load calculation process.

For more information on Tank Load Case calculations, see: The IMS Handbook.

Improving Corrosion Inspections

We have made several improvements to our circuits to simplify the process of capturing corrosion inspection results. Now, you can define default text on measurement set trend plot notes, making it easier to add standardized comments. Also, the report creation process for measurement sets has been improved. In addition, we have enhanced the 3D mapping for Condition Monitoring Locations (CMLs) with an equipment inspection tool, and you can now define CML types for each equipment group.

For more information on these circuit improvements, see: The IMS Handbook.

For information on the other IMS PEI improvements, see: PEI Release 2023.3.

IMS RCM Improvements

This time around, RCM schedules and condition histories were the main focus.

Creating Schedules & Sending Tasks to the CMMS

Earlier, we highlighted the standardization of IMS schedules and condition histories. This change is particularly significant for RCM users. Now, RCM schedules match IMS schedules in all their functionalities! This enhancement allows you to create new schedules within IMS RCM. Furthermore, these schedules now also include an event history, a management of change (MOC) verification, a manage threats & opportunities (MTO) check, a recurrence history, and a range of extra filters.

Another great addition is the capability to incorporate tasks into schedules. Tasks defined through RCM Analyses can now be included in schedules, specifying the upcoming execution date for each task. This data can then be sent to your linked computer maintenance management software (CMMS).

For more information on RCM Schedules, see: The IMS Handbook.

Turnaround Planning in RCM

Turnaround planning is now available for RCM! You can handle this through Planned Events. Just head over to My Account and activate the Planned Events menu. Once activated, you can create Planned Events that sync up with your site’s turnarounds. From there, you can attach schedules to these Planned Events and easily track their progress.

For more information on Planned Events, see: The IMS Handbook.

For information on the other IMS RCM improvements, see: RCM Release 2023.3.

IMS PLSS Improvements

The most exciting update for PLSS is the fresh new appearance of Remedial Actions. Also, it’s worth mentioning that we have tidied up the PLSS application by removing pipeline elements interactions, although the data itself still resides in the database.

New Look for Remedial Actions

We revamped the Remedial Actions view! We have removed the three tabs at the top of the page and made the Defects Plot the default view. Plus, we have merged the settings pop-up into the main display, giving you the power to choose what appears in the chart by simply ticking the checkboxes.

For more information on the remedial actions refresh see: The IMS Handbook.

For information on the other IMS PLSS improvements, see: PLSS Release 2023.3.

IMS SIS Improvements

The standardized IMS schedules and condition histories, highlighted earlier, hold great importance for SIS users. Another significant update is the introduction of the Safety Requirements Specification (SRS) report, ensuring compliance with the IEC 61511 standard. Additionally, we introduced an extra HAZOP template.

Safety Requirements Specification (SRS) Report

According to the IEC 61511 standard, every Safety Instrumented System (SIS) needs an SRS. To comply with this guideline, it is best practice to provide an SRS report to the Safety Instrumented Function (SIF) Designer. Now, within IMS SIS, you can generate this report instantly. This enhancement complements the comprehensive management of the safety lifecycle with IMS SIS, providing significant value to the Engineering Project team.

For more information on the creation of SRS reports, see: The IMS Handbook.

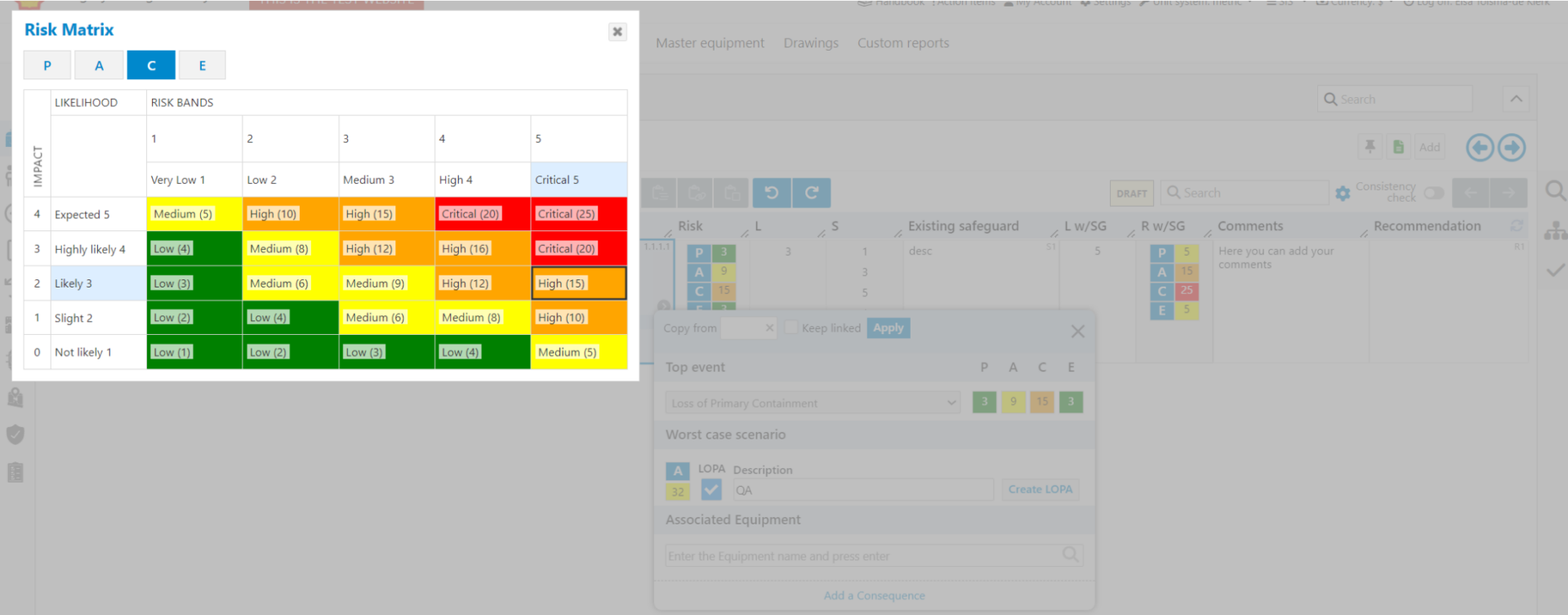

New HAZOP Template

To help comply with regional standards, an additional HAZOP template, called Residual Risk, has been added in IMS SIS. This template specifically includes a risk ranking with safeguards, in addition to a risk ranking without safeguards.

For more information on the Residual Risk HAZOP template, see: The IMS Handbook.

For information on the other IMS SIS improvements, see: SIS Release 2023.3

CMMS Improvements

Our Application Program Interface (API) documentation has received a major upgrade! Plus, SAP4HANA is now part of the list of Computerized Maintenance Management Software (CMMS) that we support.

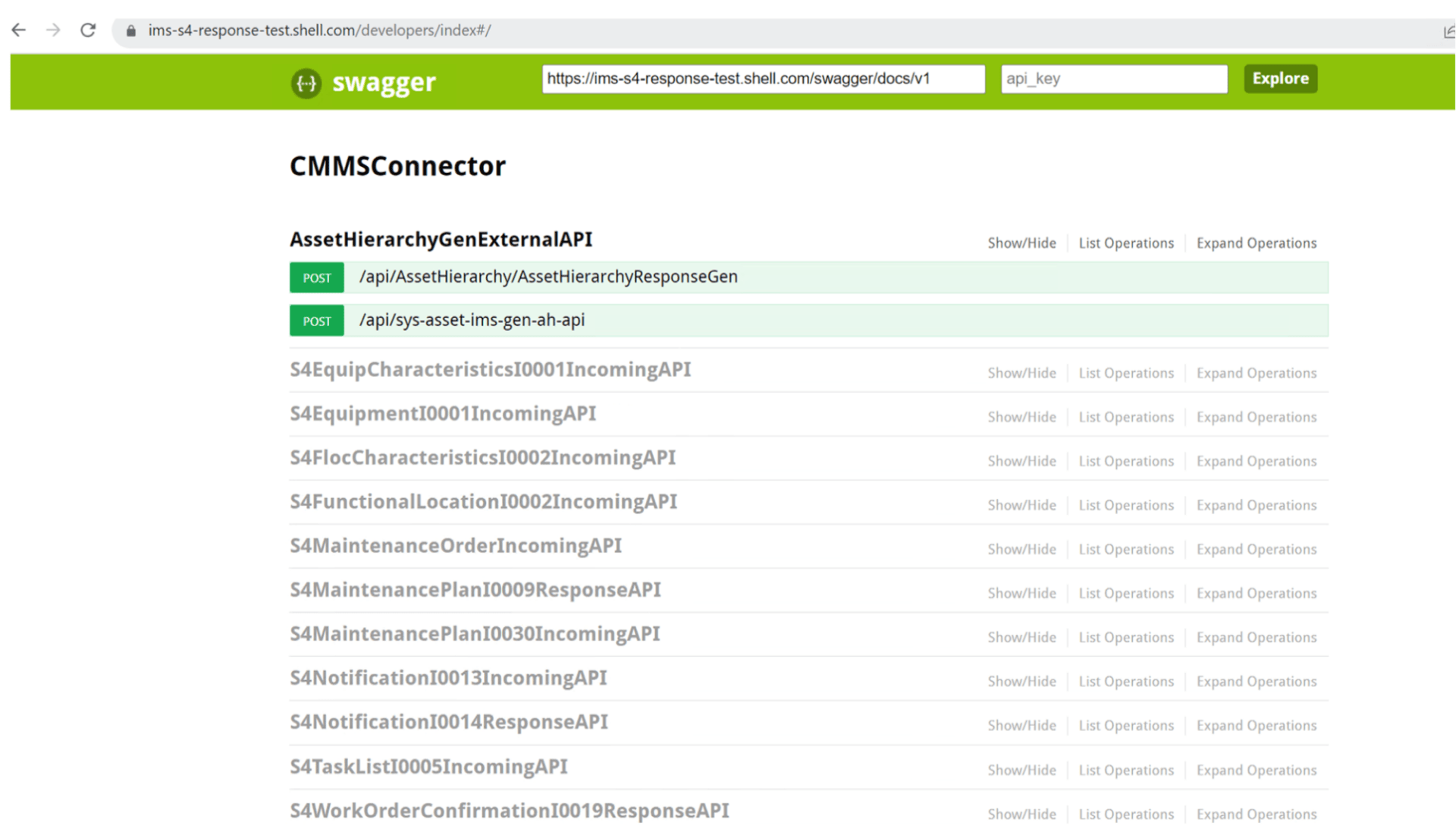

Improved Application Program Interface (API) Documentation

With the newest CMMS Connector release, we are offering CMMS documentation. If you are using the latest Connector, you can head over to /developers. There, you can check out APIs directly from the user interface and explore payload examples. This resource provides integration tips, functional insights, and troubleshooting help. It is a handy self-service tool for quick onboarding, customization, and keeping up with the latest features.

Interfacing with SAP4Hana

IMS now supports interfacing with SAP4Hana! What CMMS do you use? Cenosco can help you interface your CMMS with IMS.

For information on the other IMS CMMS improvements, see: CMMS Release 2023.3.

Questions?

Fill out the form below to contact us

Elsa Tolsma-de Klerk Technical Writer

Elsa is an engineer who enjoys bringing people together through knowledge. She has a Master’s in Electronic Engineering and spent over 10 years at Sasol, a global petrochemical company. There, she began her career as an Advanced Process Control Engineer, gaining hands-on experience in process optimization and control systems, while also discovering a talent for writing detailed operating philosophies. Since 2019, she’s brought that mix of engineering know-how and writing skills to her role as a Technical Writer at Cenosco, and now leads the team that looks after the IMS knowledge base and training Academy.