Equipment Maintenance Management Software is a type of software designed to assist businesses and organizations in managing the maintenance and upkeep of their equipment and machinery.

It is a valuable tool for industries that rely heavily on equipment, such as manufacturing, construction, transportation, healthcare, etc.

Equipment Maintenance Management Software provides a centralized platform where users can track, schedule, and manage all aspects of equipment maintenance, ensuring that machines operate efficiently, breakdowns are minimized, and downtime is reduced.

Index

The Benefits of Equipment Maintenance Management Software

Facts and Figures about Equipment Maintenance Management Software

Equipment Maintenance Management Software in the Oil & Gas and Chemical Processing Industries

FAQ: Frequently Asked Questions about Equipment Maintenance Management Software

The Benefits of Equipment Maintenance Management Software

A good Equipment Maintenance Management Software offers many benefits to businesses and organizations that rely on equipment and machinery for their operations.

Increased Equipment Uptime

Using equipment maintenance software helps create regular maintenance schedules, which means fewer unexpected breakdowns and more uptime for the equipment.

Regular check-ups and maintenance tasks also help keep the equipment in good condition and work better.

Reduced Maintenance Cost

By scheduling regular maintenance and tracking equipment performance, businesses can avoid costly emergency repairs and minimize the need for major replacements. This leads to lower maintenance expenses over time.

Extended Equipment Lifespan

Properly maintained equipment tends to last longer. Equipment maintenance software ensures that equipment receives timely inspections, servicing, and part replacements, which can extend the lifespan of valuable assets.

Improved Efficiency and Productivity

Equipment maintenance software streamlines maintenance workflows, allowing technicians to access work orders, instructions, and information efficiently. This leads to faster response times, reduced downtime, and improved overall productivity.

Enhanced Safety and Compliance:

The software helps organizations adhere to safety standards and compliance requirements. Regular maintenance ensures that equipment is in safe working condition, reducing the risk of accidents and liability issues.

Data-Driven Decision-Making

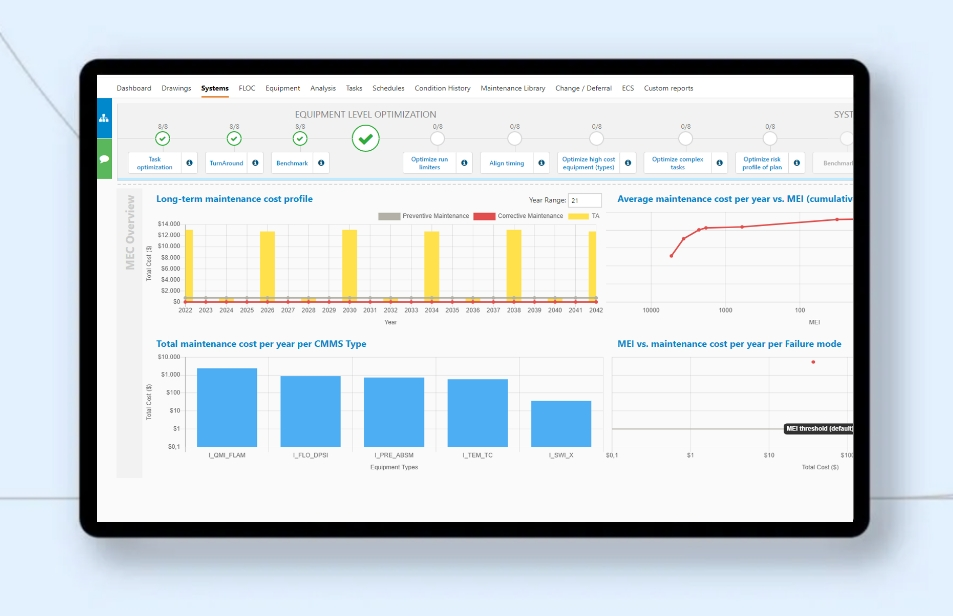

Equipment maintenance software generates reports and analytics, providing valuable insights into equipment performance, maintenance costs, and other metrics. Organizations can use this data to make informed decisions about maintenance strategies and asset management.

Facts and Figures about Equipment Maintenance Management Software

Can Equipment Maintenance Management Software be customized to suit specific industry needs and equipment types?

Yes, the software can be tailored to meet the unique requirements of various industries and types of equipment. It allows businesses to adapt the software to their specific workflows, compliance standards, and reporting needs, making it a versatile tool for a wide range of businesses.

How does Equipment Maintenance Management Software improve communication and collaboration among maintenance teams and stakeholders?

Equipment Maintenance Management Software provides a centralized platform where maintenance teams, managers, and other stakeholders can access real-time updates and collaborate effectively. It streamlines communication by enabling technicians to receive work orders and instructions promptly. Managers can monitor the progress of maintenance tasks and make data-driven decisions based on performance reports and analytics. This improved communication fosters better coordination and ensures that everyone stays informed about maintenance activities.

Contact Us

Learn more about the leading

Asset Integrity Management Software