Meet the IMS Software Suite

Unified asset

integrity software

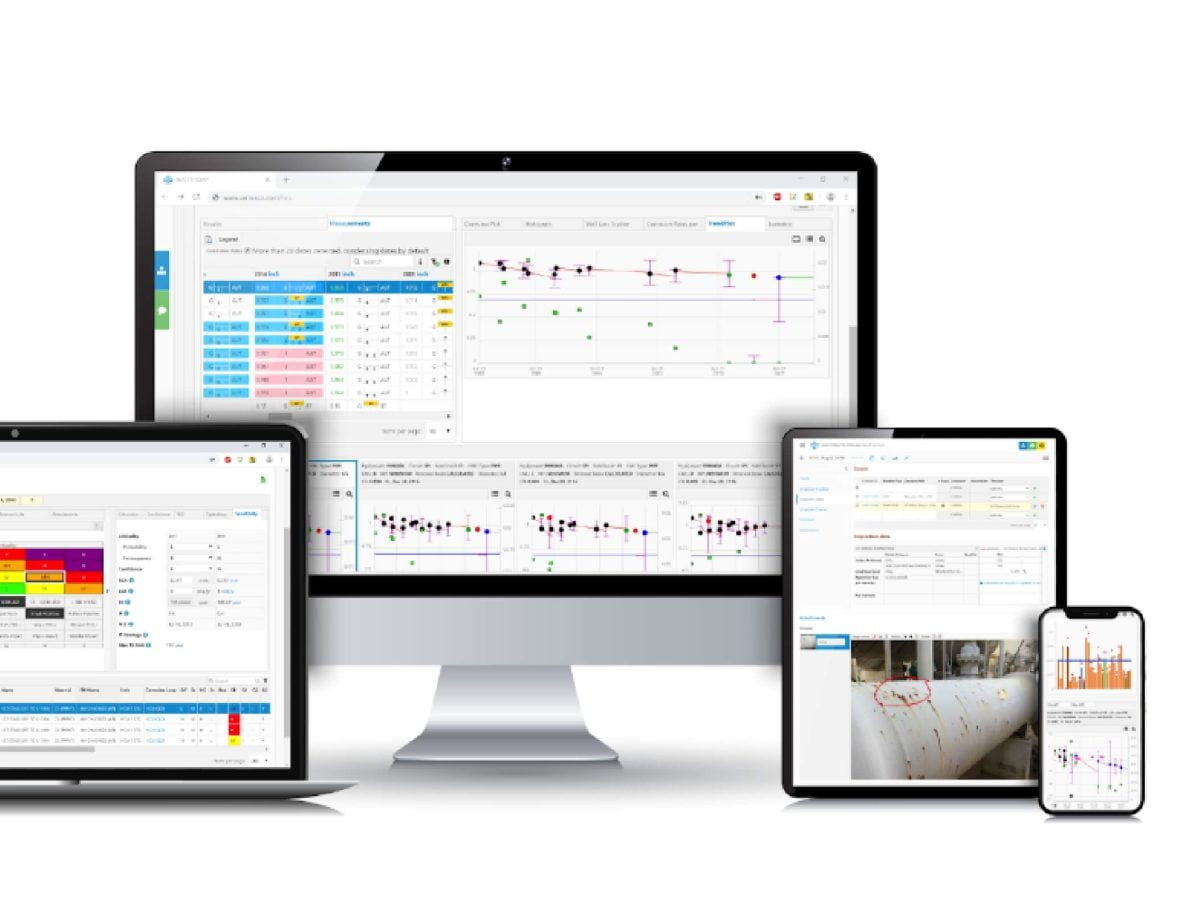

Our solutions safeguard integrity, reliability, and instrumentation safety in asset-intensive industries. With IMS you will automate manual tasks (inspections, report generation, approvals) to free up engineering time (inspections, automated report generation and data sync with CMMS/ERP).

Transision from a fragmented, manual-intensive asset integrity system to a unified, automated platform with Cenosco, ensuring a cohesive user experience and minimizing inefficiencies.

Trusted worldwide – Cenosco IMS is an enterprise-grade platform, with deep domain expertise

Benefits of IMS Implementation

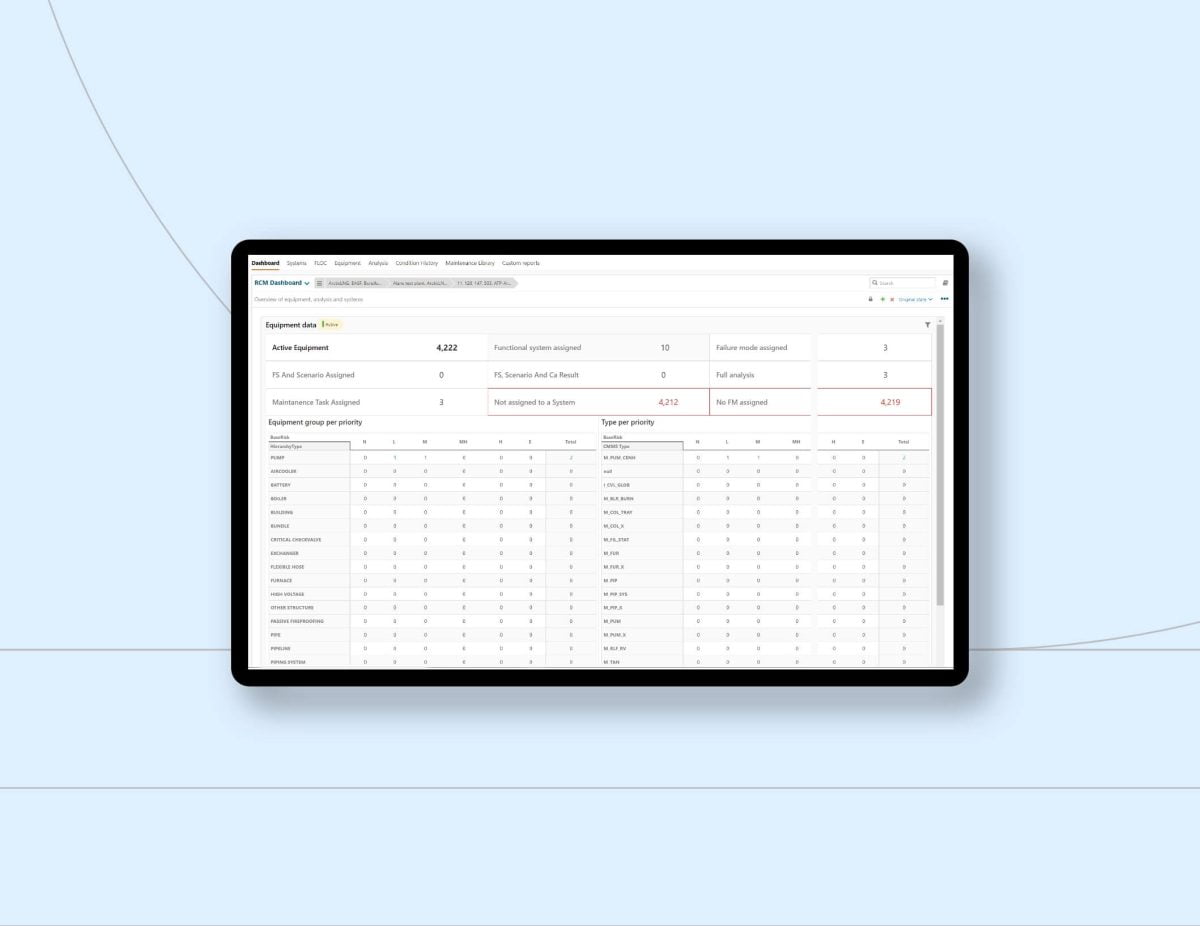

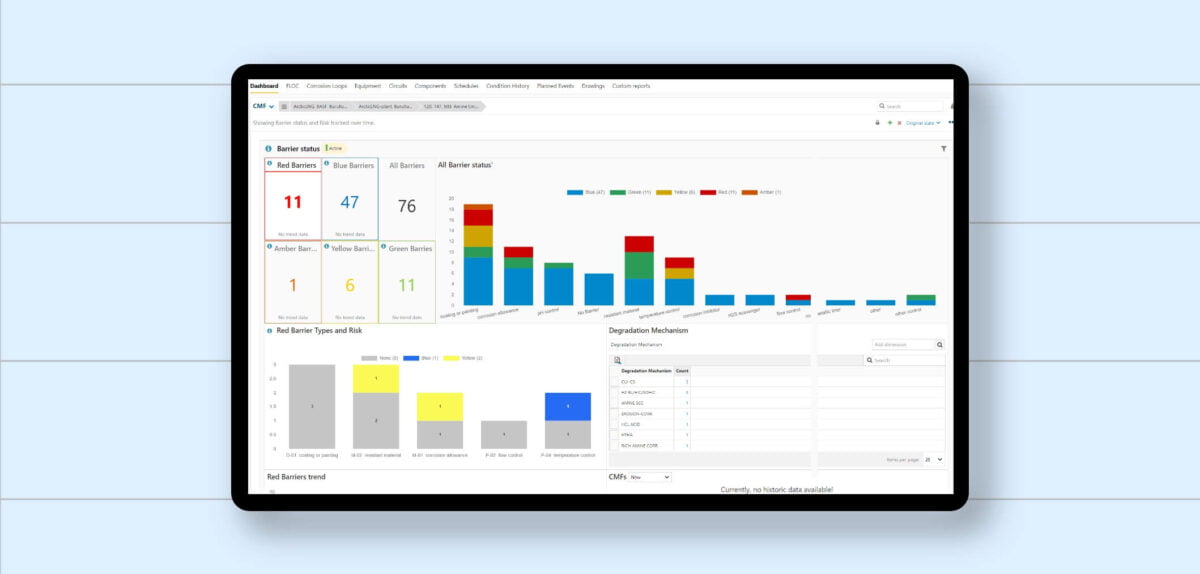

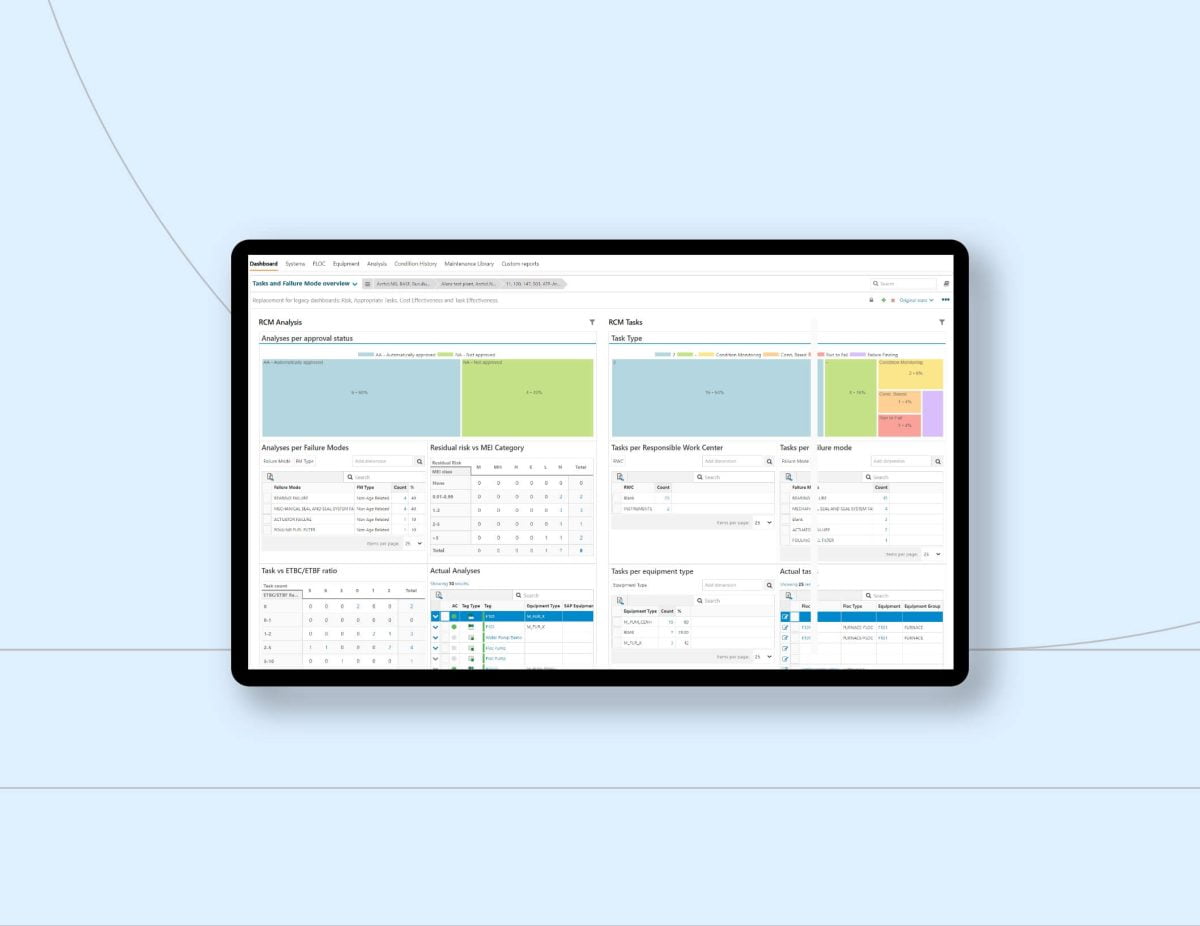

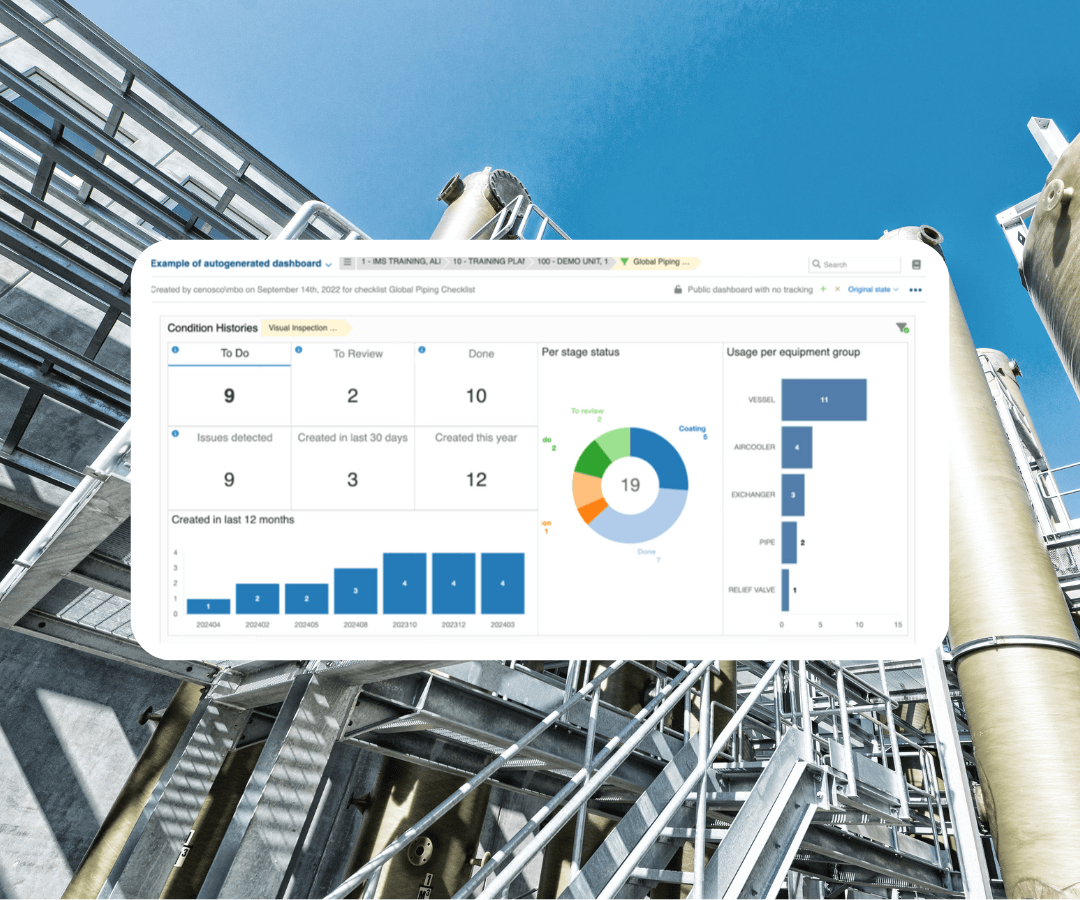

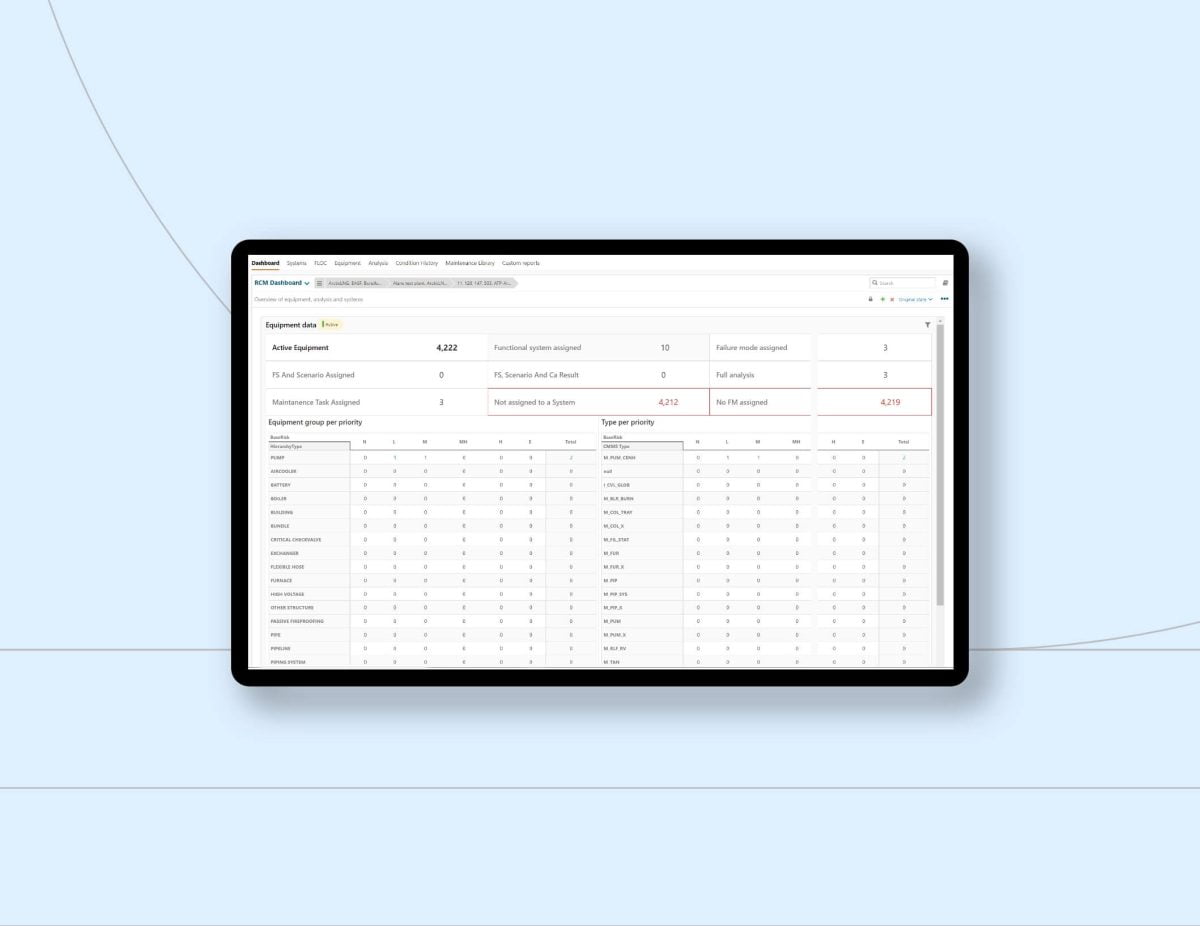

Monitoring dashboard

Task grouping and scheduling

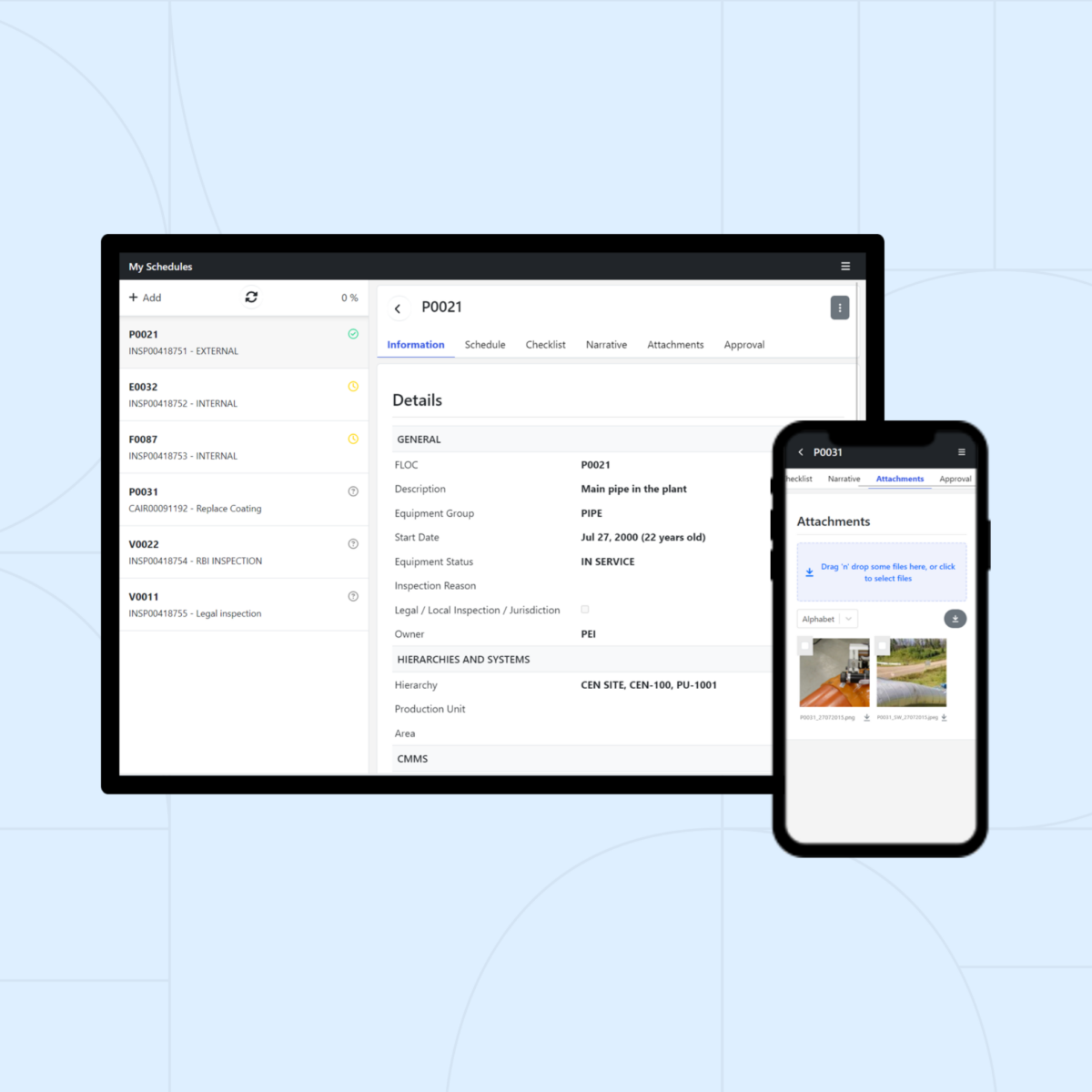

Field execution with mobile

Reporting

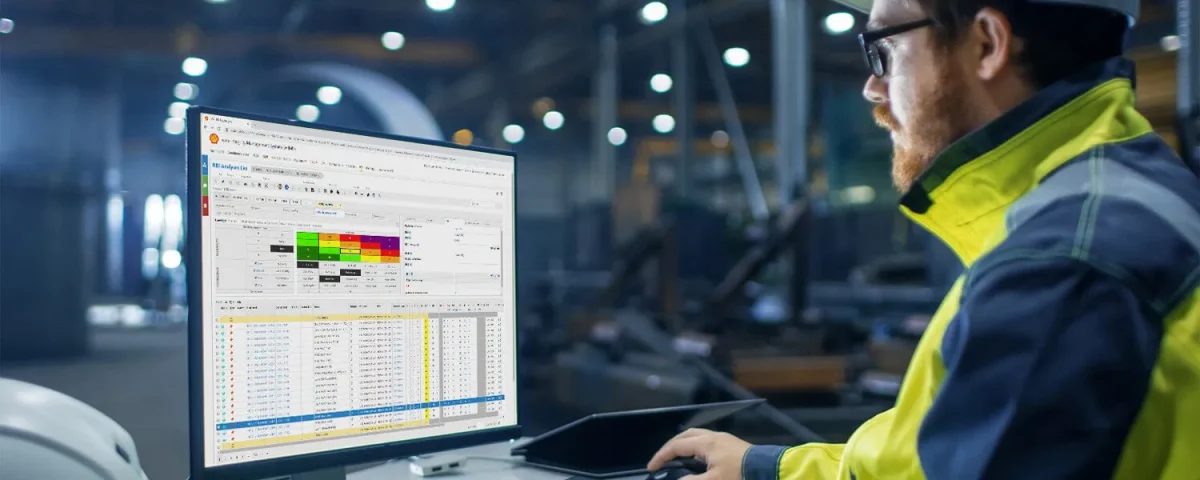

Data input and analysis

End-to-end visibility

Advanced features

IMS Suite Core Features

All disciplines in one platform, integrated with other enterprise systems. Comprehensive asset lifecycle management, advanced analytics, reporting, improved data accuracy, and more!

Asset Hierarchy

Keep your asset register clean and organized.

Interface to ERP systems

Such as SAP, JDE, Maximo, and more.

Offline mobile functionality

Ease inspections when out in the field.

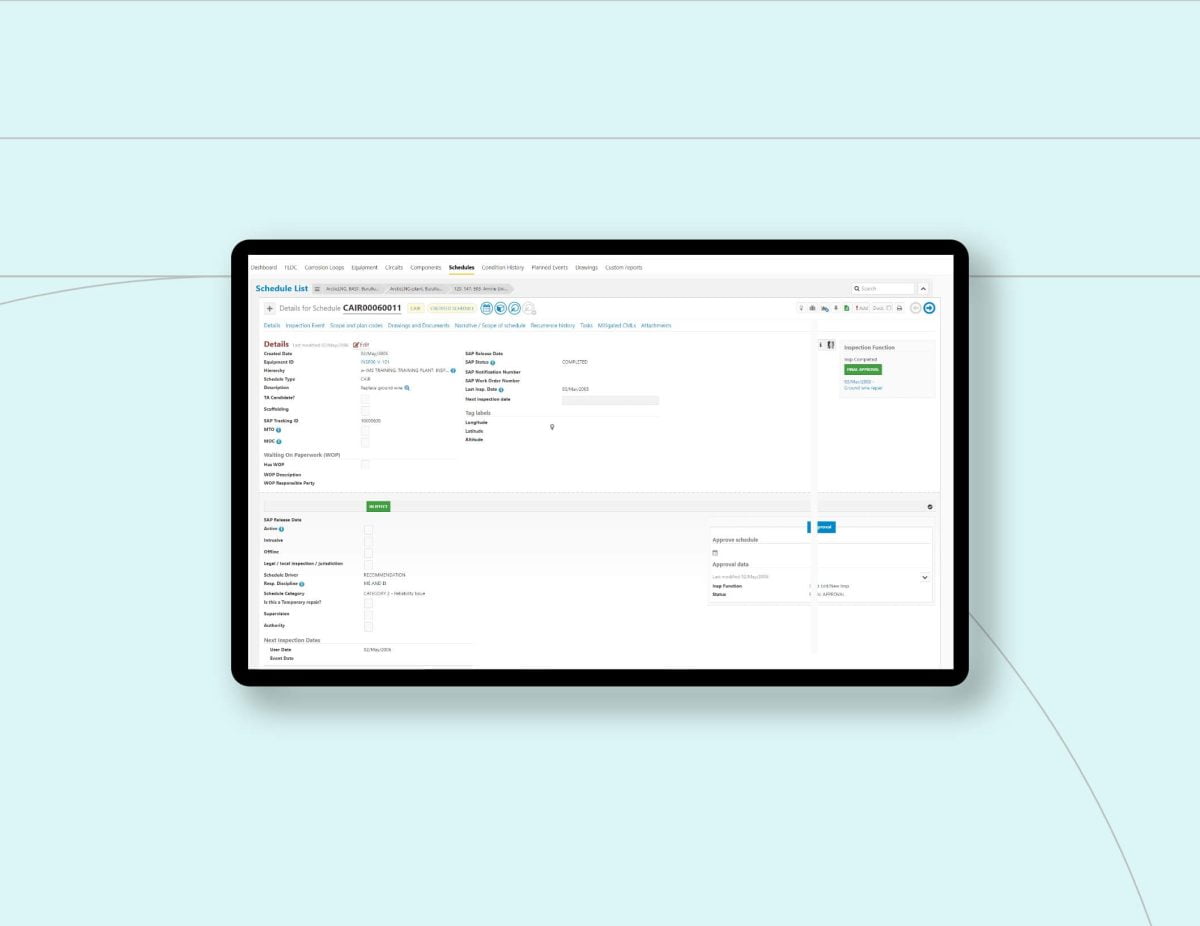

Scheduling

Transform all your analyses into a planned schedule or maintenance strategy.

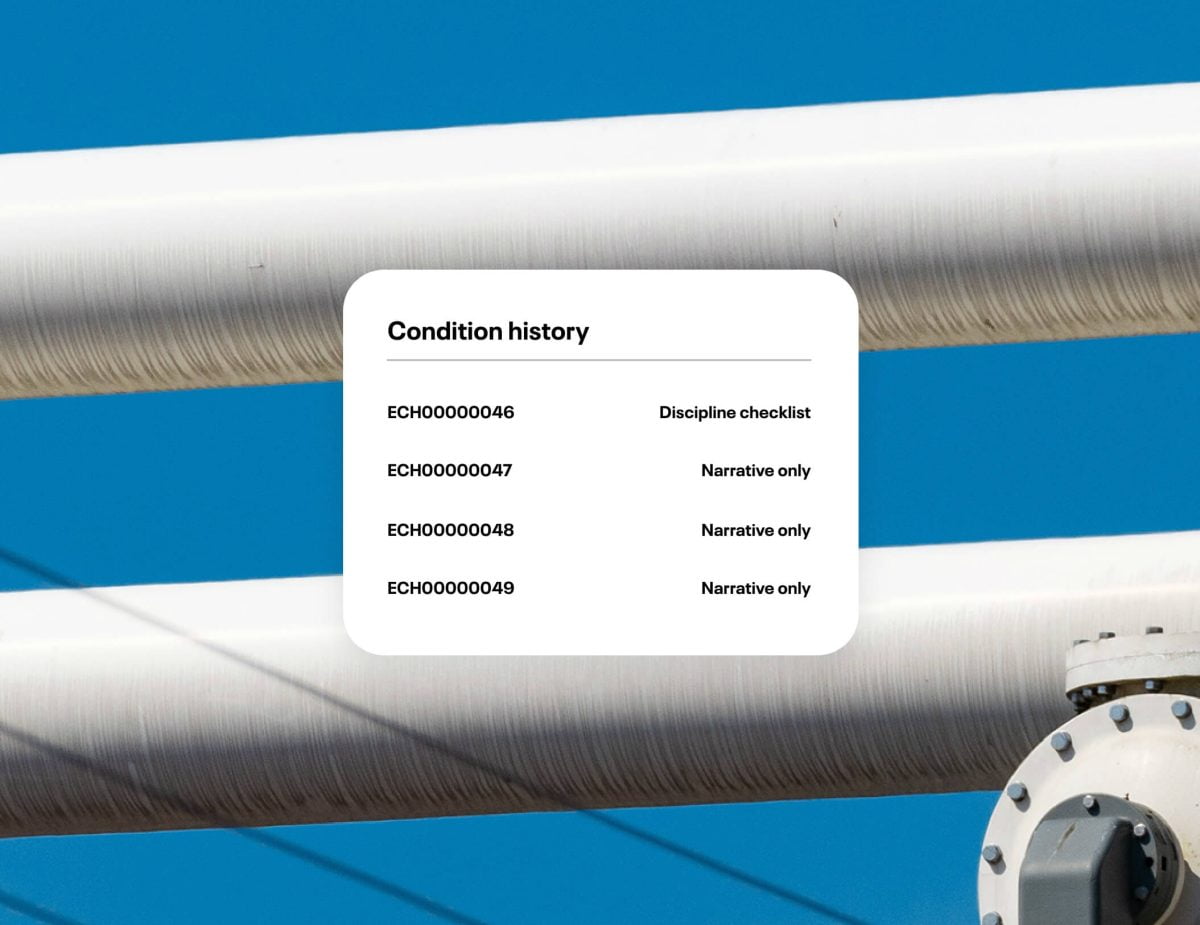

Condition History

Track all events in the lifetime of your equipment, from inspections to leaks to temporary repairs.

Configurable Dashboards

Visualize the most relevant data to you.

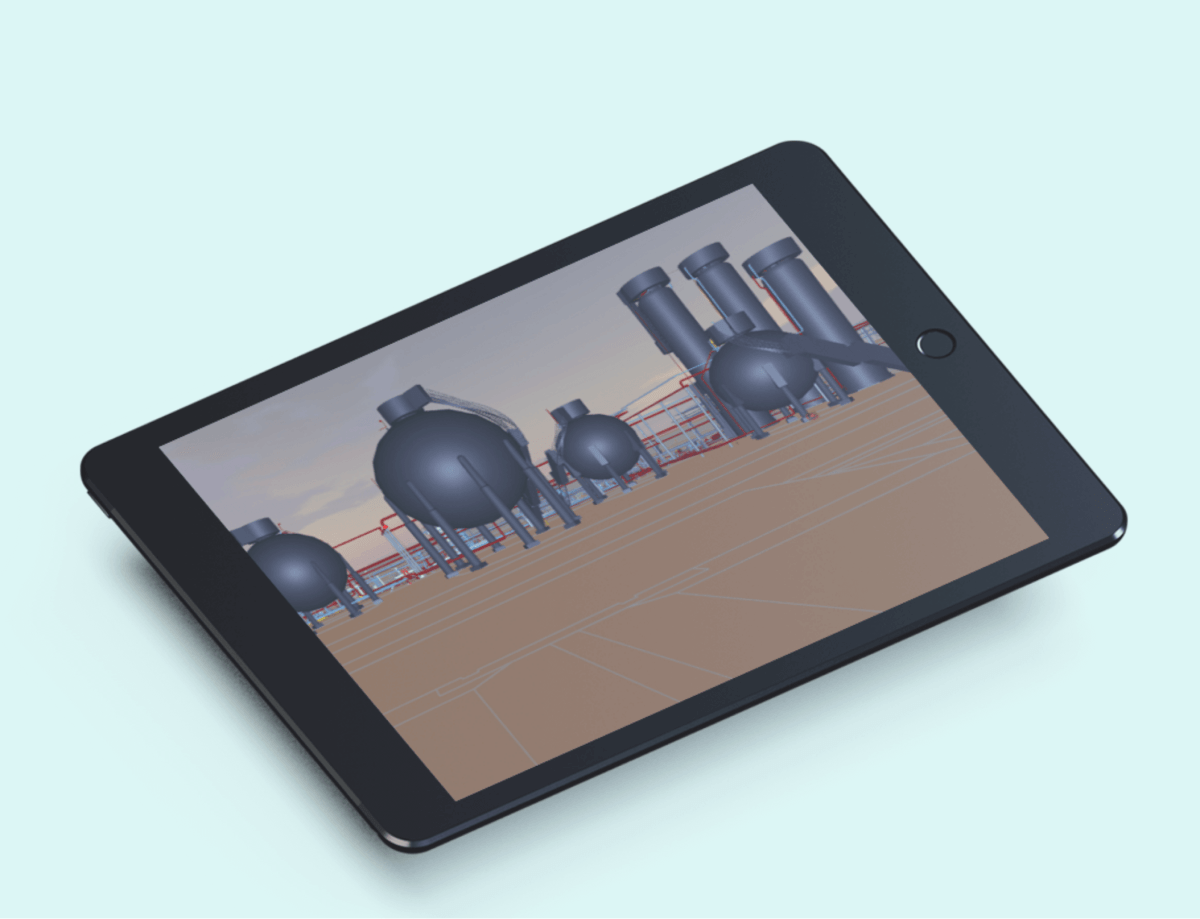

2D and 3D Capabilities

Enhance your inspection data by visualizing it into 2D drawings or 3D models.

Compliance

Meet compliant regulations through proper condition history.

Insights into bad actors

Use your data to stay ahead of the curve of bad actors and your equipment’s performance.

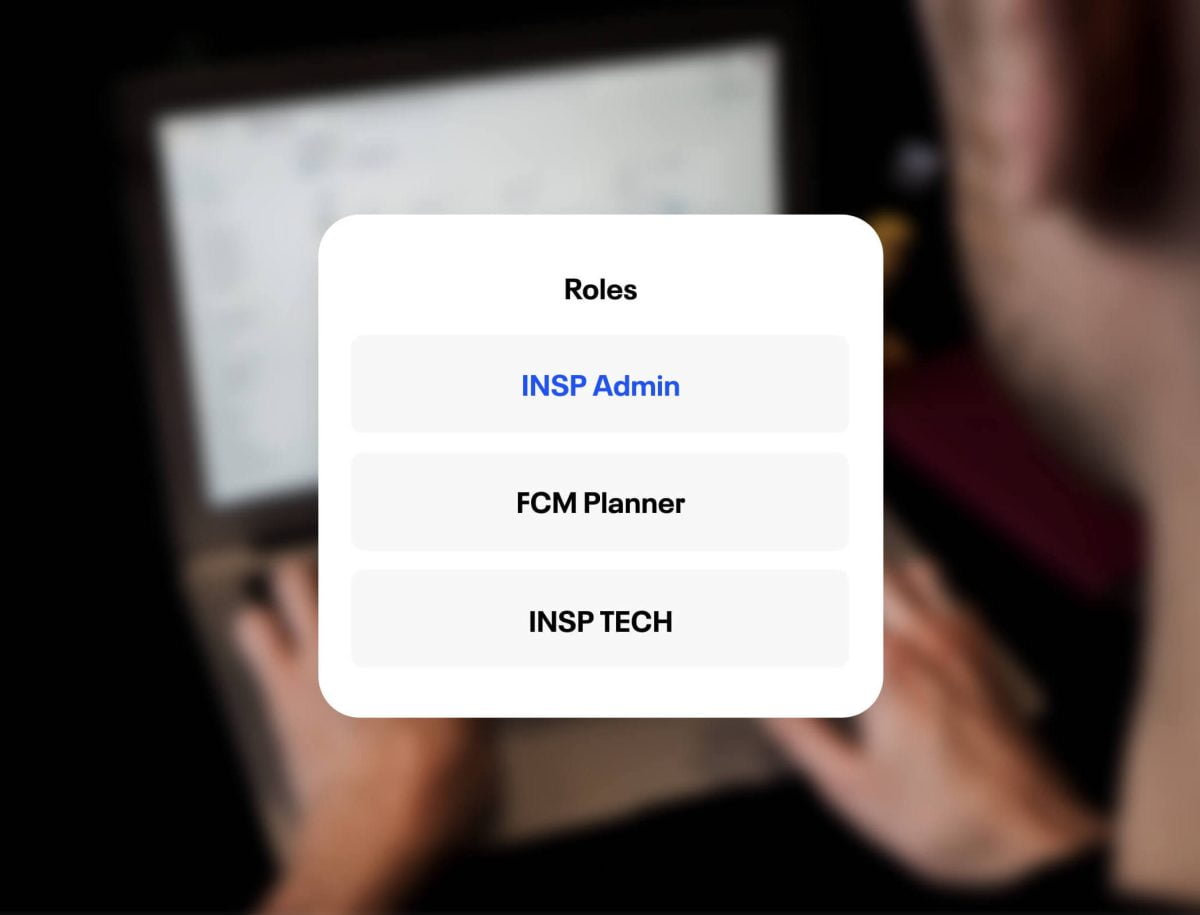

Tailor-Made Roles

Set up your user profiles based on different disciplines.

IMS4Field

Embrace the ease of digital checklists for all your field work.