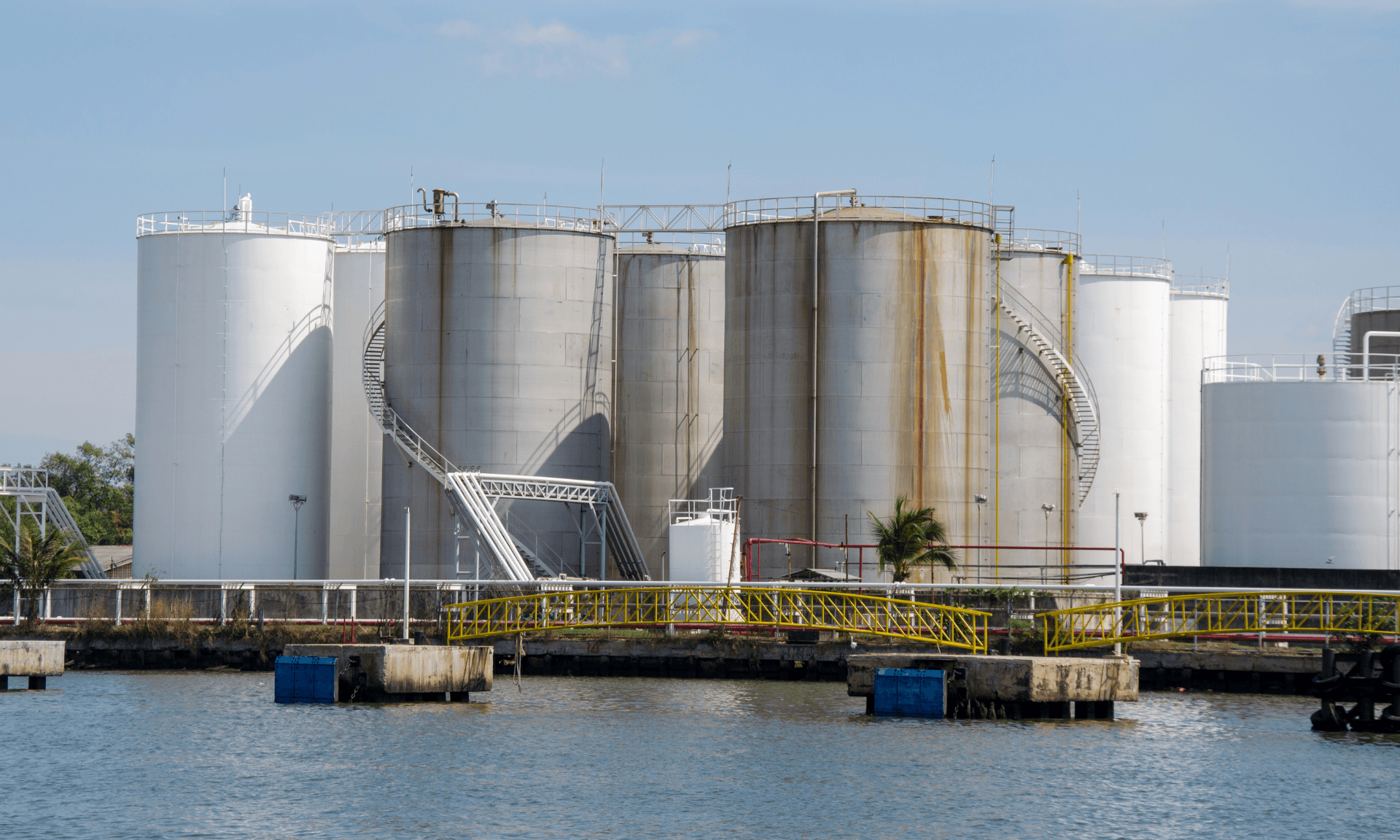

Operating across the Caribbean Islands, this oil and gas supermajor manages a vast network of onshore and offshore facilities spanning over 1,200 acres. With a workforce of around 2,000 employees, the company plays a critical role in the energy sector and holds a majority stake in one of the world’s largest natural gas liquefaction facilities. This integrated gas operation not only serves the petrochemical market but also supports the company’s broader strategic objectives.

For over 20 years, the company has been using Cenosco’s IMS (Integrated Management System) software solutions to protect its assets, streamline operations, and ensure the integrity of its critical infrastructure. Despite this robust foundation to safeguard their operations, the size and complexity of the company’s asset base made it challenging to manage certain “bad actors”. In order to prevent the underperforming assets from negatively impacting operational reliability and availability, the company sought to establish a structured approach for managing bad actors and optimizing asset performance.

While the company’s initial approach was to conduct in-house Reliability Centered Maintenance (RCM) studies, they quickly realized that bringing in experts would facilitate the processes and ensure results for this complex project. This is when MaxGrip was brought in, a global consultancy firm in asset performance management with proven experience in deploying RCM studies and extensive knowledge of Cenosco’s IMS Suite. If you’d like to read the full business case, click here.

The Results: 2.35 MM USD yearly savings

With this first stage of the RCM study project completed, a lot of bad actors were resolved thanks to 946 new equipment care tasks of which 67 are Preventive Maintenance (PM). Based on failure history, 158 tasks could be decreased in frequency. Based on all of these and other results, the efficiency increased and costs went down:

- Production gain of 1% thanks to increase in reliability. This translates to 2.3 MM USD per year

- Decrease of man hours translating to 50,000 USD yearly

- Keeping in mind that these results were realized on only the first scope, we expect the results to significantly increase for this energy company.