If you work in maintenance, you’ve probably been caught off guard by a machine failure that derailed your entire day. What started as a minor hiccup quickly snowballed into costly downtime, tanking productivity and spiking stress levels faster than a pressure valve failure. In the oil and gas industry, where asset reliability is non-negotiable, even a single breakdown can trigger a chain reaction across production. Suddenly, you’re stuck playing catch-up, juggling limited resources and tight timelines.

In this article, we will dive deeper into how maintenance scheduling software addresses these challenges through data analysis and strategic processes, systematically identifying potential vulnerabilities and scheduling preventive interventions. By keeping critical assets maintained on time it prevents costly breakdowns, extends equipment life, and optimizes operations. Within the highly regulated oil and gas industry, where safety and compliance are paramount, effective maintenance supported by advanced scheduling tools ensures consistent production, compliance, and asset integrity.

But first, let’s see what preventative maintenance is, why it needs to be scheduled, and why we need dedicated maintenance scheduling software.

What Is a Maintenance Schedule?

A maintenance schedule is a detailed plan that specifies what maintenance tasks need to be done, when, and on which equipment or assets. It includes preventive maintenance like inspections, lubrication, part replacements, corrective repairs, and condition-based actions. But an effective schedule does more than organize tasks; it aligns resources, minimizes unexpected outages, and safeguards performance and safety.

Why Schedule Preventive Maintenance?

When we talk about maintenance scheduling, we primarily refer to preventive maintenance. This is a type of maintenance that is done ahead of failures; it is done deliberately and regularly. So, it must be planned. And a robust maintenance plan demands a well-defined strategy.

To build an effective plan, maintenance teams must:

- Identify all the equipment of the given asset.

- Understand the potential failure modes for each piece of equipment, as well as the consequences these failures could have in terms of safety, environmental impact, and economic cost.

- Tailor maintenance efforts according to risk levels and cost effectiveness.

This methodology embodies a risk-based approach, grounded in empirical data and quantitative analysis. Risks are assessed using historical records, observed degradation trends, manufacturer data, and expert insights from maintenance personnel but also assessments of both the likelihood and potential impact of failures. Consequences must be well understood and quantified for precise risk evaluation.

Within this framework, maintenance efforts are tailored to the level of assessed risk – higher risks warrant more maintenance, while lower risks require less intervention. The estimated risk level, often quantified in monetary terms per year, effectively sets the maintenance budget. Typically, it is considered appropriate to allocate up to one-third of the annualized risk value to maintenance expenditures.

The credibility of risk assessment is vital, as it underpins the effectiveness of the entire maintenance strategy. The risk-based approach forms the core of Reliability Centered Maintenance (RCM), which requires the consideration of two scenarios:

- The risk of doing no maintenance.

- The cost of doing maintenance and the effects of it on risk reduction.

This balance can ensure that maintenance activities are cost-effective and beneficial to overall operations. Effective maintenance planning involves understanding degradation mechanisms, potential failures, consequences, and their impacts. Using criticality metrics alongside the Maintenance Efficiency Index, which quantifies risk reduction relative to maintenance costs, enables maintenance actions to be justified through data-driven, financially sound reasoning.

When done properly, preventative maintenance scheduling reduces failures, optimizes resource use, and supports regulatory compliance while safeguarding people, the environment, and company assets.

The Role of Maintenance Scheduling Software

Maintenance scheduling software provides the structure and efficiency needed to apply preventive and risk-based maintenance approaches. Instead of scrambling after failures, you gain control and manage maintenance with precision. Cenosco’s IMS Reliability Centered Maintenance software, built on the RCM business process designed to optimize the performance of physical assets by implementing the most efficient maintenance strategies, empowers you to:

Know Your Equipment

Before you schedule anything, you must know your assets inside out. This requires building a detailed inventory that includes equipment hierarchy, functions, and known causes of failure. Without this foundation, prioritizing maintenance or assessing risk is nothing more than guesswork. IMS RCM helps you establish and maintain detailed asset registers where you can capture comprehensive information about your equipment, including specifications, lifecycle changes, functions and failure modes. IMS RCM also allows you to group your equipment into systems where similar functional failures may occur, enabling targeted and efficient risk-based maintenance.

Know Your Risk

Identify the risks each asset carries. Understand how failures impact safety, the environment, and cost. Quantify those risks to target your maintenance dollars efficiently and effectively. IMS RCM helps you identify and quantify risk by assessing each asset’s failure likelihood and impact using historical data, degradation trends, manufacturer input, and expert insights. It monetizes risk through the Maintenance Efficiency Index (MEI), in order to tell you if your strategy is cost-effective.

Do the Analysis

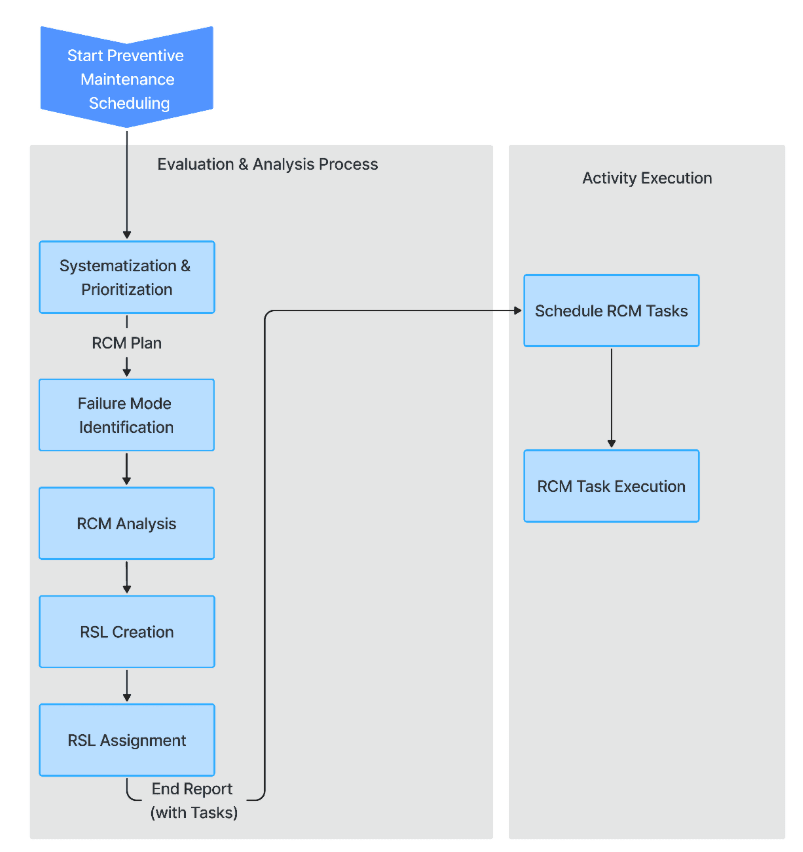

This is where risk-based and RCM analyses turn data into action. Inputs include condition monitoring, historical data, and degradation models. Key steps:

- Identify main failure modes.

- Evaluate failure frequency and impact.

- Match risks to optimal maintenance types—whether time-based, preventive, or “run-to-failure.”

IMS RCM acts as your decision engine, delivering maintenance strategies that are specifically aligned with the unique demands of each asset. It leverages the Reliability Strategy Library (RSL), a comprehensive, professionally curated database of proven maintenance strategies and preventive tasks. In addition, it incorporates Equipment Care Strategies, which are standardized, data-driven methodologies aimed at improving asset reliability and operational cost-effectiveness by providing precise, optimized maintenance actions.

Implement the Analysis

Turning RCM strategies into reality is where IMS RCM scheduling software shines. It helps you:

- Convert RCM output into schedules and maintenance tasks and workflows that can easily be sent to any CMMS.

- Group tasks efficiently to reduce downtime and disruption.

- Use templates and recommendations that simplify routine processes.

- Maintain regulatory alignment and operational oversight.

Implementing IMS RCM software shifts maintenance practices from a reactive, problem-solving approach to one that is proactive and data-driven. You’re building comprehensive asset hierarchies, mapping out which components are most at risk, and spinning up maintenance plans from solid RCM analysis. The result? You’re not just hoping things don’t fail, you’re actually minimizing downtime and squeezing every bit of value from your resources.

It ticks off all the major boxes: regulatory compliance, asset longevity, improved safety—basically all the metrics that matter in oil and gas, where a single slip-up can cost a fortune (or worse). You can finally focus on reliability and uptime instead of scrambling to put out fires, and there’s a real, measurable payback.

Request a Demo

Ready to move from reactive to reliable? Get a personalized demo of IMS RCM. Fill out the form below to get started.

Denis Tkalec Technical writer

Denis Tkalec is a technical writer at Cenosco, specializing in asset integrity management software since 2022. With a background in education and six years in marketing, she turns complex topics into clear, user-friendly content. Inspired by Camus’s belief that “a writer keeps civilization from destroying itself,” she brings precision and care to every manual.