In 2025, we transitioned from a three-year release cycle to monthly releases. The adoption of a monthly release cycle ensures we deliver updates to our IMS products consistently and predictably. This approach intends to prioritize enhancements and new features resulting in significant improvement to product performance, reliability, and overall user experience. In this blog post, we cover some of the highlights from our recent releases in 2025 Q1 & Q2 (2024.3, 4.0, 4.1, 4.2, 4.3, and 4.4).

Index

IMS Platform Improvements

IMS PEI Improvements

IMS RCM Improvements

IMS SIS Improvements

IMS PLSS Improvements

IMS FCM Improvements

IMS Platform Improvements

With the last few releases of IMS, we have constantly strived to enhance the user experience on our IMS Platform and provided several new features and enhancements to simplify your workflows. One of our highlights is the introduction of Schedule Tasks in IMS Platform which aims to provide a simplified process to plan and execute all your inspection and maintenance strategy on a particular equipment.

Schedule Tasks Introduced: Unified planning and execution of strategies

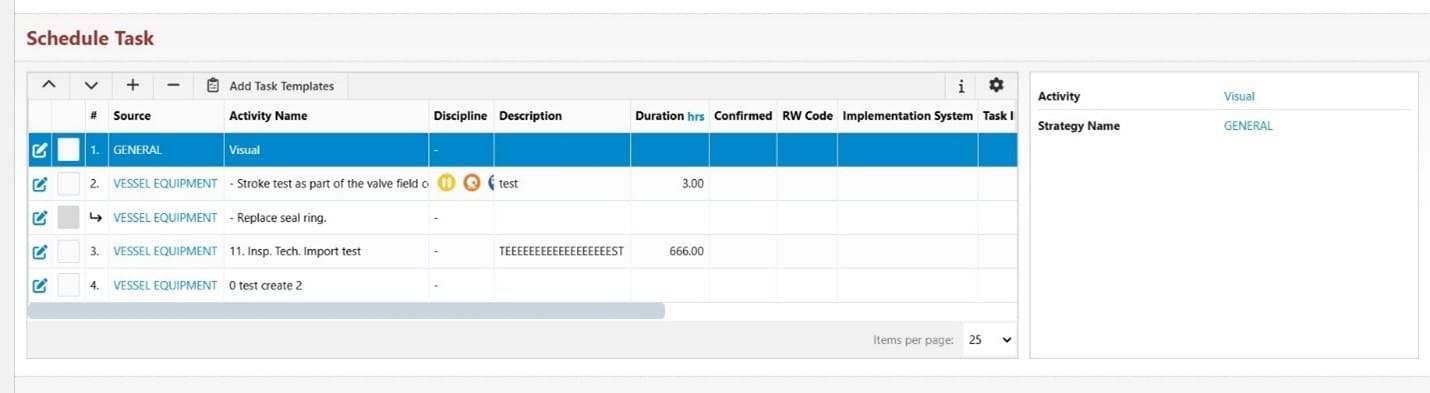

IMS has made schedule planning and execution more straightforward by introducing the ability to add Tasks, Subtasks, and Activities directly into Schedules and Condition Histories across all modules. A new section for Schedule Tasks on the Schedule Details Page simplifies this process, providing clear guidance on what needs to be accomplished during execution.

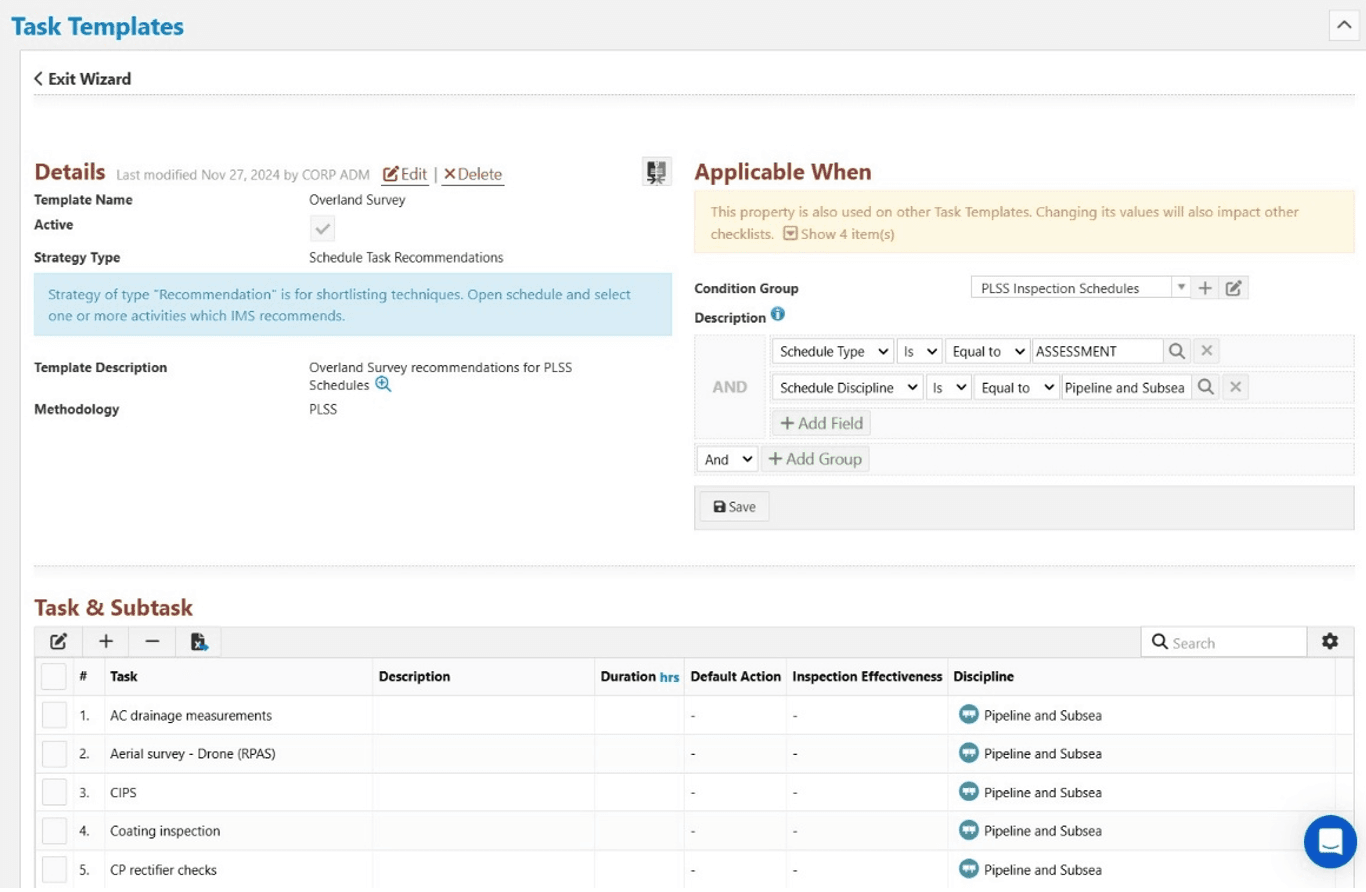

To further enhance this functionality, we have rolled out three types of Task Templates – namely Schedule Task Recommendations, Schedule Task Templates, and Risk-Based Inspection Templates which are in alignment with best practices aimed at boosting the consistency, efficiency with which field workers record the data from their inspection and maintenance rounds. Below, you will see a Schedule Task Recommendation template made for pipeline elements which can be shared and reproduced with ease across equipment.

For more information on the new Task workflow, see: The IMS Handbook.

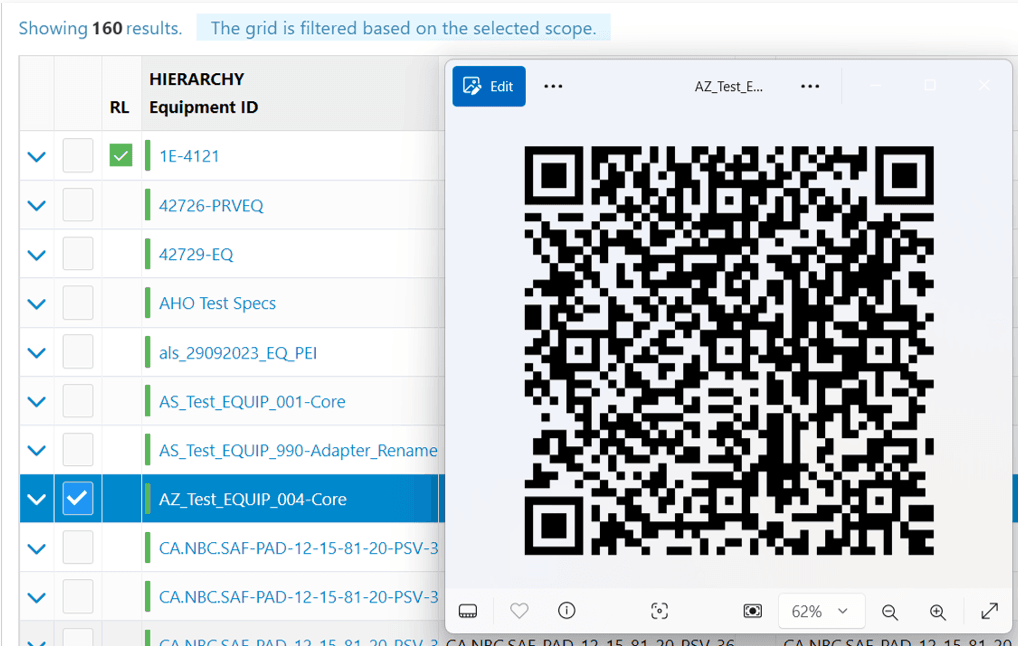

QR code generation for Equipment ID across IMS

QR code export functionality, previously exclusively on FCM has now been extended across all IMS modules—PEI, PLSS, RCM, SIS, and TAT, making it simpler to access equipment data on the go. You can now easily export QR codes with convenient options to print or download them as transparent .png files. The QR functionality is supported by dynamic forms, equipment tagging, and observations making accessing equipment information faster and more intuitive. Now, all other field users besides those of IMS FCM can profit from efficiency gains and time saving.

For more information on the QR code improvement, see: The IMS Handbook.

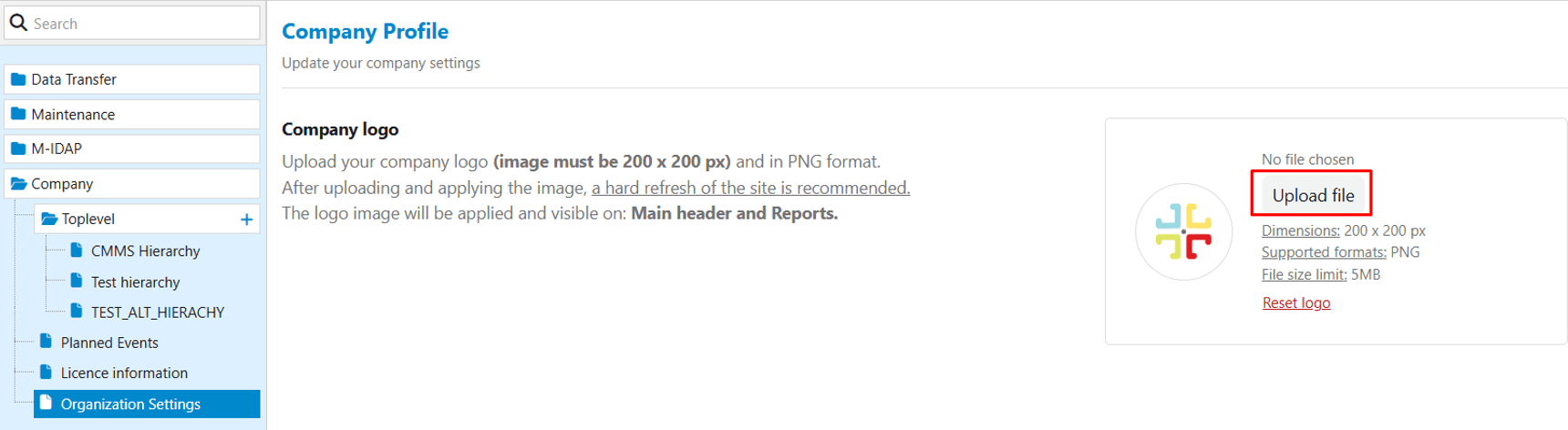

Introducing Logo Personalization in IMS

IMS now enables organizations to personalize their branding by uploading their company logo. The site administrator can manage logos for the IMS site header and reports through the new Organization Settings repository. Simply upload a 200×200 pixels PNG image, preview it, and apply the changes to see your branding across the platform after a quick refresh. This feature is one of our many steps toward more customizable settings for our customers.

Sharing Dynamic Form Configuration

Dynamic Forms, the most beloved feature among our users, received several enhancements over the last releases. It is now incredibly straightforward to share your Dynamic Form configuration. It is as simple as downloading your form as a .dform file and then uploading it to another environment within the same site. This enables you to preserve all your configurations, lookup lists and logic – all of it without having to recreate it repeatedly. This import and export functionality of the Dynamic Form structure in the design wizard will surely ensure uniform data collection in Dynamic Forms uniform, be it in acceptance or production environments.

Other noteworthy enhancements to Dynamic Forms with an emphasis on improving usability, flexibility, and efficiency have been rolled out in the recent releases. Some of those noteworthy updates include more intuitive inputs and improved navigation which aim to support daily operational tasks more effectively.

For more information on the export and import of a Dynamic Form structure, see: The IMS Handbook.

IMS PEI Improvements

As a part of our ongoing commitment to include the most sought after compliance to API 580 and 581 in our RBI module, our teams have been working tirelessly to deliver an all-rounded RBI module in our IMS PEI software.

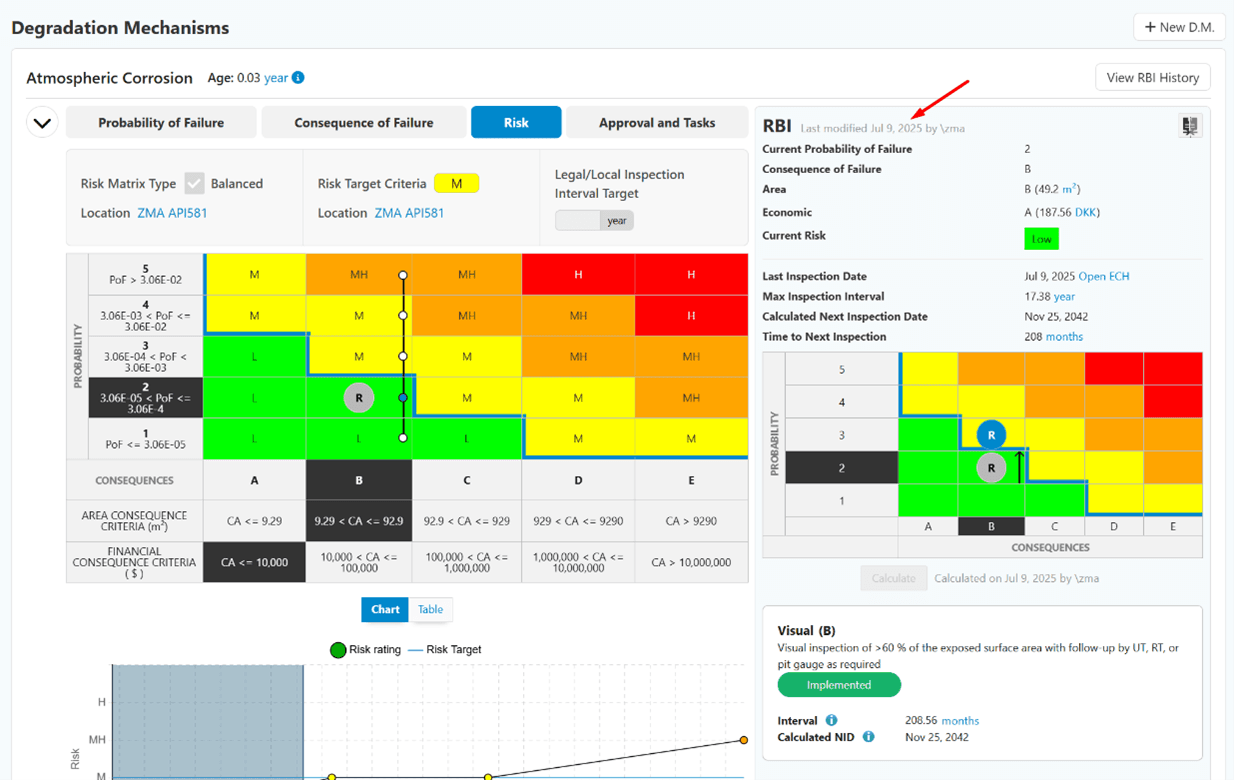

API RBI 581 is now available in IMS PEI

IMS PEI proudly expands its RBI module capabilities with comprehensive support for API 581 Risk-Based Inspection (RBI) methodology (2016 edition with 2019 and 2020 addendum) for pressure equipment, including piping, pressure vessels, and tanks. The inclusion of this new RBI methodology in our already comprehensive IMS PEI module in addition to the choice of a API 580 aligned S-RBI empowers our customers with enhanced flexibility in managing asset integrity and risk. Users have the choice to choose between a fully quantitative, industry wide standard API 581 RBI methodology and a qualitative, and semi-quantitative S-RBI methodology. Both methodologies adhere to the API 580 standard, ensuring industry compliance regardless of the chosen risk based inspection methodology that best fits your strategy. We at Cenosco can help you determine the right fit based on your risk strategy, operational needs and data maturity levels.

For more information on API RBI 581 in IMS, see: The IMS Handbook.

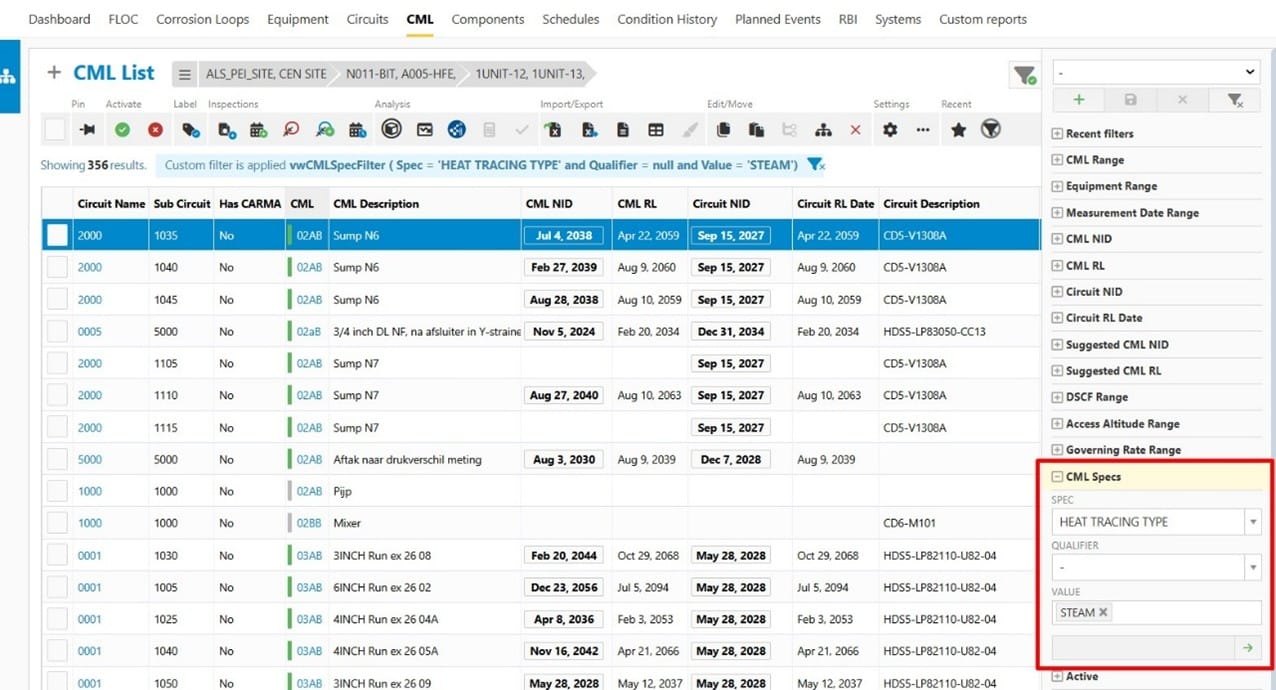

Circuit Improvements

IMS PEI has been enhanced with several key improvements for Circuit management. To facilitate precise data handling, users can now filter Circuits by Spec Name directly from the Circuit Main Screen. It is now possible to export and update specifications using the Hierarchy Specs Importer. Users can now assign Default values for Schedule Category and Schedule Driver through Settings to ensure consistent scheduling. Additionally, two new user-defined Measurement Set Queries allow for improved tracking of pending and completed on-stream NDT inspections. A notable UI improvement is the addition of a new Action Item button on the Circuit Details page that provides the users with quick access.

For more information on some of these notable improvements to Circuits, see: The IMS Handbook.

New PEI Roles

IMS PEI has updated user roles to improve inspection and corrosion workflows. Users now have roles that can be assigned to them which confers them with additional rights within IMS. The CORROSION GENERAL role manages circuits, CMLs, measurement sets, and corrosion scheduling. The INSPECTOR role focuses on Equipment Condition Histories and crediting schedules. The INSP PLANNER, replacing the clerk role, handles comprehensive schedule management with discipline-based permissions.

For more information on PEI roles and for what they can and cannot, see: The IMS Handbook.

IMS RCM Improvements

Our Reliability Software, IMS RCM saw some essential updates to ensure our stable IMS RCM software takes advantage of all the recent IMS platform updates.

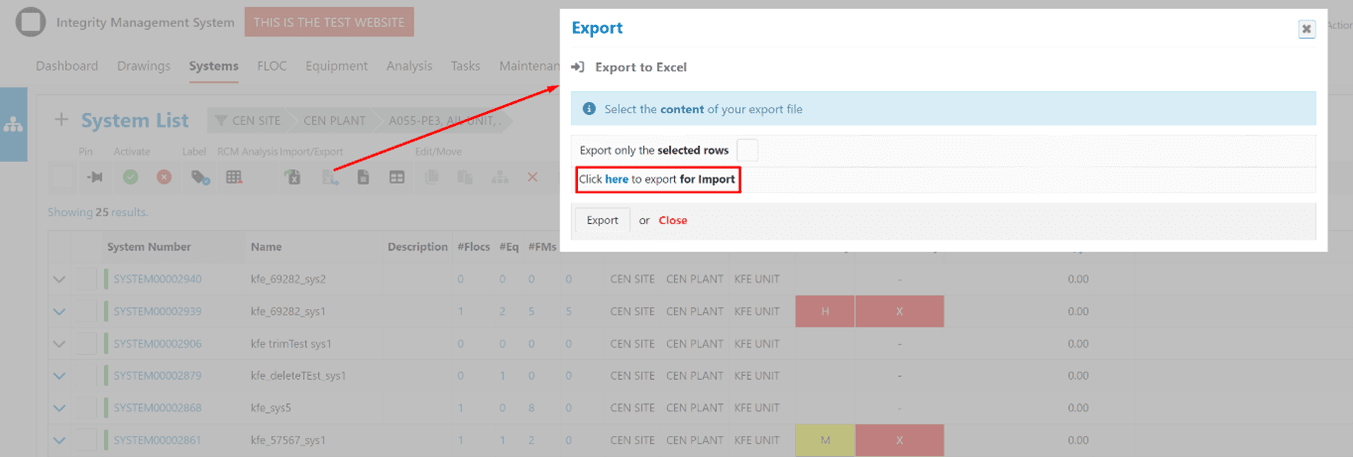

System Improvements

IMS RCM now offers a handy “Export for Import” feature for Systems, making it easy to manage and reuse your system data. You can effortlessly export one or more Systems into an .xlsx file, which includes all the important details along with any related functions and functional failures. This simplifies data handling, helps with bulk updates, and makes system configuration and replication more efficient for our IMS RCM users. Another update to the Systems is the ability to filter them based on a range filter, allowing you to find the system you are looking for in the grid.

For more information on the System Export for import functionality see: The IMS Handbook.

Uploading Tasks in bulk

The new bulk upload feature for RCM Tasks is set to revamp the RCM workflow. You can effortlessly import or update Inspection Techniques directly from the Settings toolbar, simplifying task management. Additionally, our Schedules now allow for the direct addition of Tasks, moving beyond the outdated Schedule Plan Codes. Whether you’re utilizing RCM analyses, task templates, or your engineering expertise, all Tasks are efficiently tracked from planning through execution in Condition History.

This smoother workflow allows you to manage an end-to-end strategy where you can design activities and monitor their real-world execution with confidence.

For more information on uploading RCM Tasks see: The IMS Handbook.

IMS SIS Improvements

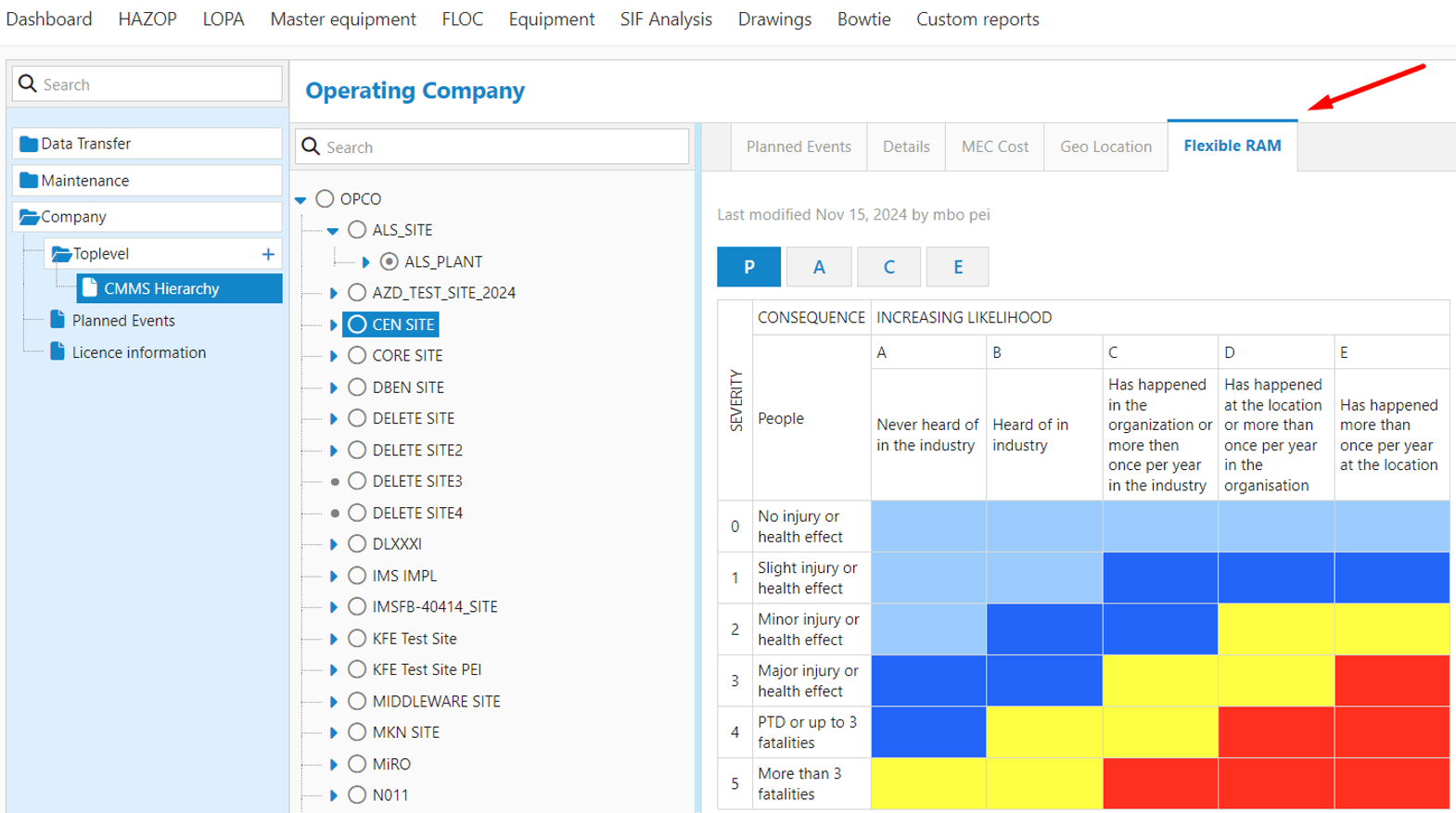

We have been onboarding more of our SIFpro users and the one common feedback we receive from all of them is how IMS SIS now enables them to manage their safety instrumented systems all in one software. The recent releases focused on stability and performance of IMS SIS, enabling a flexible risk matrix that facilitates every organization to customize it based on their risk factors, their occurrence probability and the consequences.

Flexible Risk Matrix (RAM)

An exciting update to IMS SIS now offers customers the ability to customize the Risk Assessment Matrix (RAM) to suit their specific site needs. You can request a custom RAM during setup, which allows you to define the matrix elements while keeping the standard PACE categories: People, Assets, Community, and Environment. For those who set up non-default RAM, your assessment summary will contain a single set of Tolerability Criteria (TC) that perfectly fits your requirements. Additionally, the improved hazard assignment feature allows you to assign risks at the site, plant, or unit level to ensure the risks always match your ground reality.

For more information on the Flexible Risk Matrix see: The IMS Handbook.

Stand-alone SIF Analysis

Our IMS SIS users will be excited to learn that you now conduct complete SIF risk assessments directly without needing a linked LOPA. This change allows you to automate important calculations like RRF, PFD, SIL, and λd consistently with less manual work. It’s noteworthy to mention that you will have the freedom to link it to a LOPA later. The overall SIL, with or without a linked LOPA to a SIF, will vary based on your site’s specific setup. With this feature, we have delivered a major improvement toward a more flexible, efficient, and user-friendly safety analysis workflow.

For more information on the standalone SIF Analysis, see: The IMS Handbook

IMS SIS Study Management

We now have an easier and more flexible way to manage HAZOP, LOPA, and SIF studies with our newly updated “Study Details” tab. A standout feature is the ability to create and manage multiple Sessions for each Study, so you can have different team compositions and keep track of attendance for each one. Take advantage of the option to copy and take over details from previous Sessions to save time.

For more information on Study Group Composition in IMS SIS, see: The IMS Handbook.

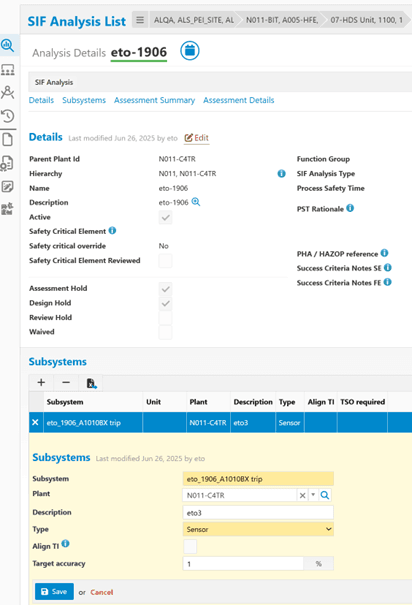

Subsystem Management Improvements

The SIF Designers in IMS SIS can now edit Subsystem parameters within the SIF Analysis or the SIS Subsystem Settings. Any changes to Subsystems used only in Draft SIFs will sync across all linked analyses and update in SIS Settings and take effect after Final Approval. For Subsystems in Final Approved SIFs, edits are restricted until approval. Once approved, linked SIFs revert to Draft status and inherit the updates. This new functionality provides you with control, flexibility, and consistency in SIF design.

For more information on the Subsystem change rules, see: The IMS Handbook.

IMS PLSS Improvements

Our Pipelines and Subsystems module received updates focused on more accurate tracking of defects over time.

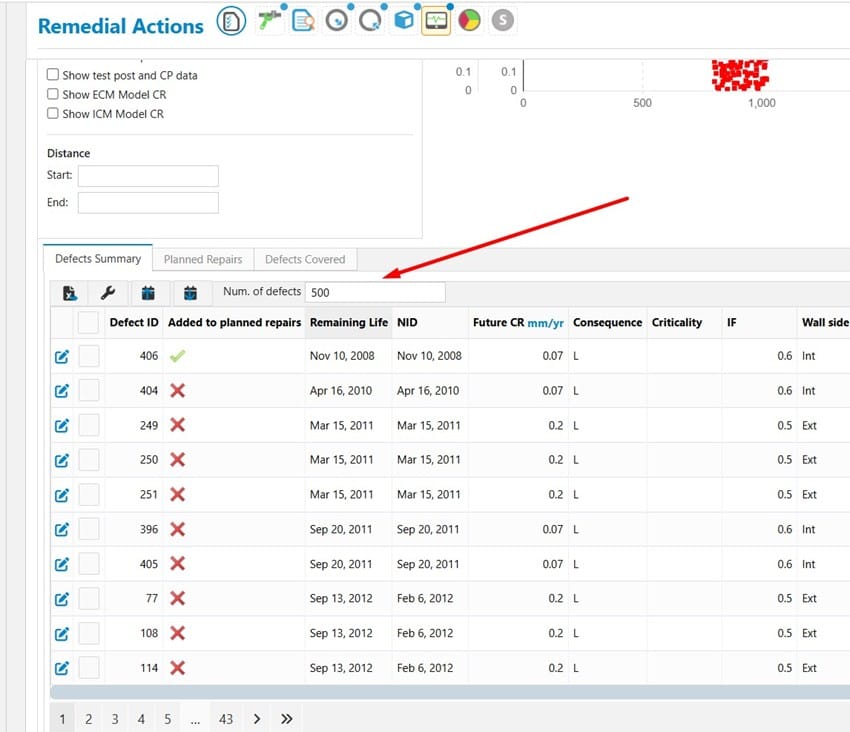

Remedial Actions Improvements

We have added a handy new feature called the “Num. of Defects” field to the Defect Summary toolbar. This allows you to choose how many of the most critical defects you want to see. The grid will automatically prioritize defects based on their Remaining Life, starting with a default view of the top 500. This makes it easier for you to focus on the highest-risk items and tackle them efficiently.

For more information on what’s new with Remedial Actions, see: The IMS Handbook.

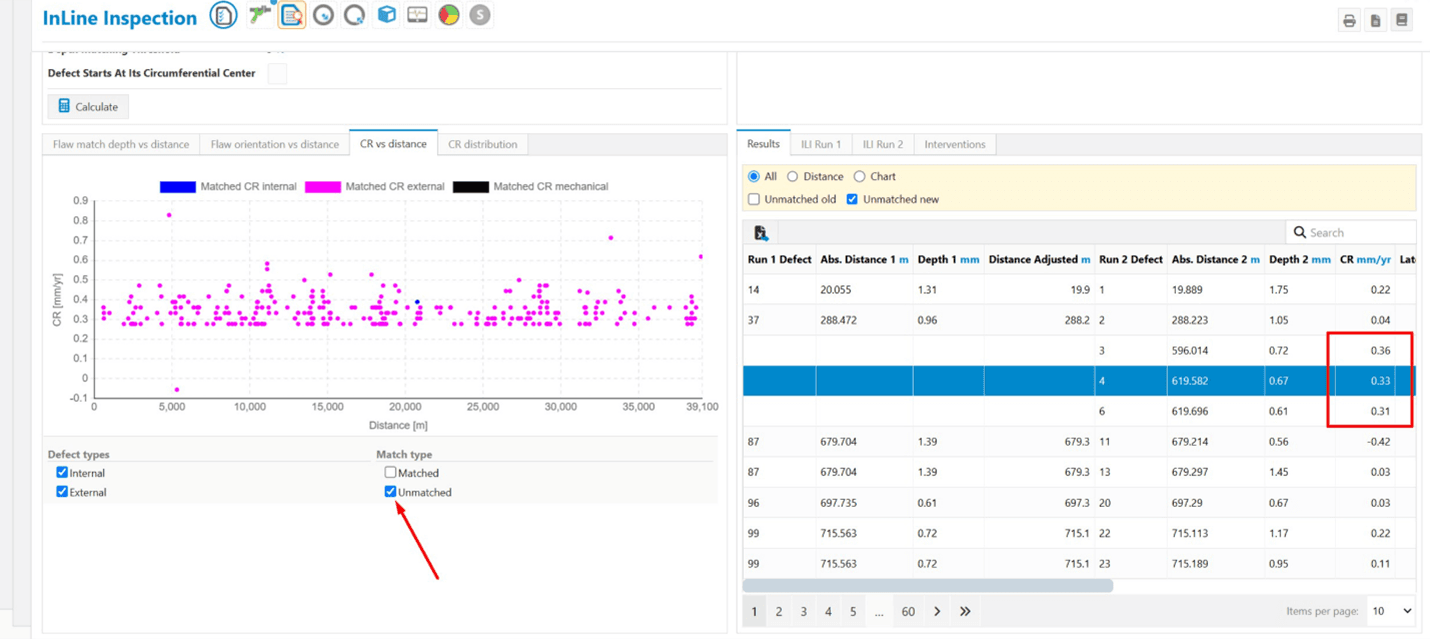

ILI Comparison Improvements

The ILI Comparison now allows you to include Corrosion Rate calculations for unmatched defects from Run 2, using zero depth and length from Run 1 as the starting point. These rates are now calculated and visually highlighted in the comparison graph, making it much easier to see how newly detected defects are growing over time.

For more information on tracking growth of defects in ILI comparison, see: The IMS Handbook.

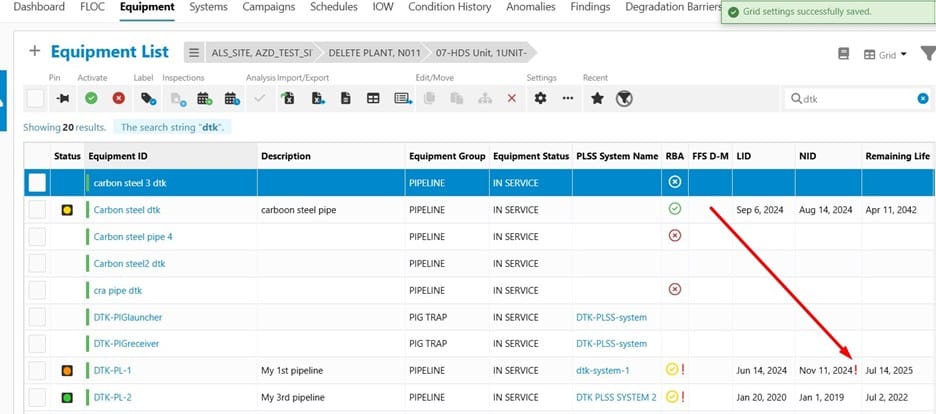

NID Override

IMS now lets you manually override NIDs through the ECH. To make things even easier, you will see an exclamation mark next to any overridden values in both the Equipment Overview Grid and the RBA Approved Summary. You also have additional options in the Conditions Found filter with some new and handy options like “Next Inspection Date Override” and “Next Inspection Date Status.” These updates will help you find and filter on inspection data more easily.

For more information on the NID override, see: The IMS Handbook.

IMS FCM Improvements

Our Flange Management Software, IMS FCM, received targeted updates to enhance clarity, streamline workflows, and align with recent improvements across the IMS platform. These updates make it easier than ever to manage flange design data and stay on top of scheduling.

User Role Updates

The FCM Engineer role has been updated to better align with its original purpose. It reflects the responsibilities that include advanced engineering tasks, like editing flange designs and performing calculations. This update helps make the role’s functions clearer and more effective.

For more information on FCM Roles, see: The IMS Handbook.

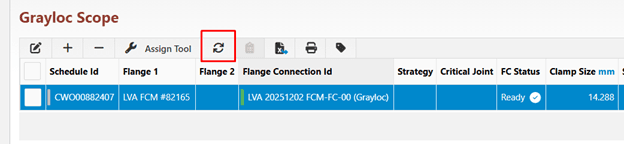

Synchronizing Flange Design

You will know from being an experienced IMS FCM user that any changes you make to the design of a Flange or Grayloc after adding the Equipment to a Job would not show up in the Job Scope. But now, you can easily update the design data of a Flange or Grayloc, and if you want, you can sync those updates to the Job Scope. For this, you will want to look for the new Sync button in the Job’s scope section.

For more information on the new Sync button for synchronizing design data, see: The IMS Handbook.

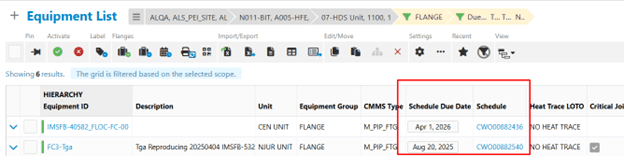

Updated FLOC and Equipment Main Grids

The improvement now allows you to easily see the next schedule related to a FLOC or a specific piece of equipment, along with its due date. You can also use the convenient filtering option so you can sort by schedule due date and status.

For information on the other Release improvements see: Release Notes.

Take note that you need to log into IMS Handbook in order to see the Release Notes section.

Take your IMS knowledge to the next level

Master any IMS module with Cenosco Academy’s self-paced e-learning. Fill out the form below to get started.