In the IMS Release 2023.2, our main goal was to improve the user experience by making our IMS processes more efficient and straightforward. Let’s take a peek at some of the coolest new features!

IMS Platform Improvements

With this release our focus was on improving the field worker experience. We’ve also upgraded our 3D capabilities and we kept working on Dynamic Forms to improve the user experience.

IMS4Field

We’ve got a shiny new mobile app called IMS4Field. It is a sleek, and focused version of IMS, perfect for all your inspection, maintenance, and testing needs. It helps focus inspection workflows by using dynamic forms checklists in Equipment Condition Histories (ECHs). The best part? You can use it offline while working in the field.

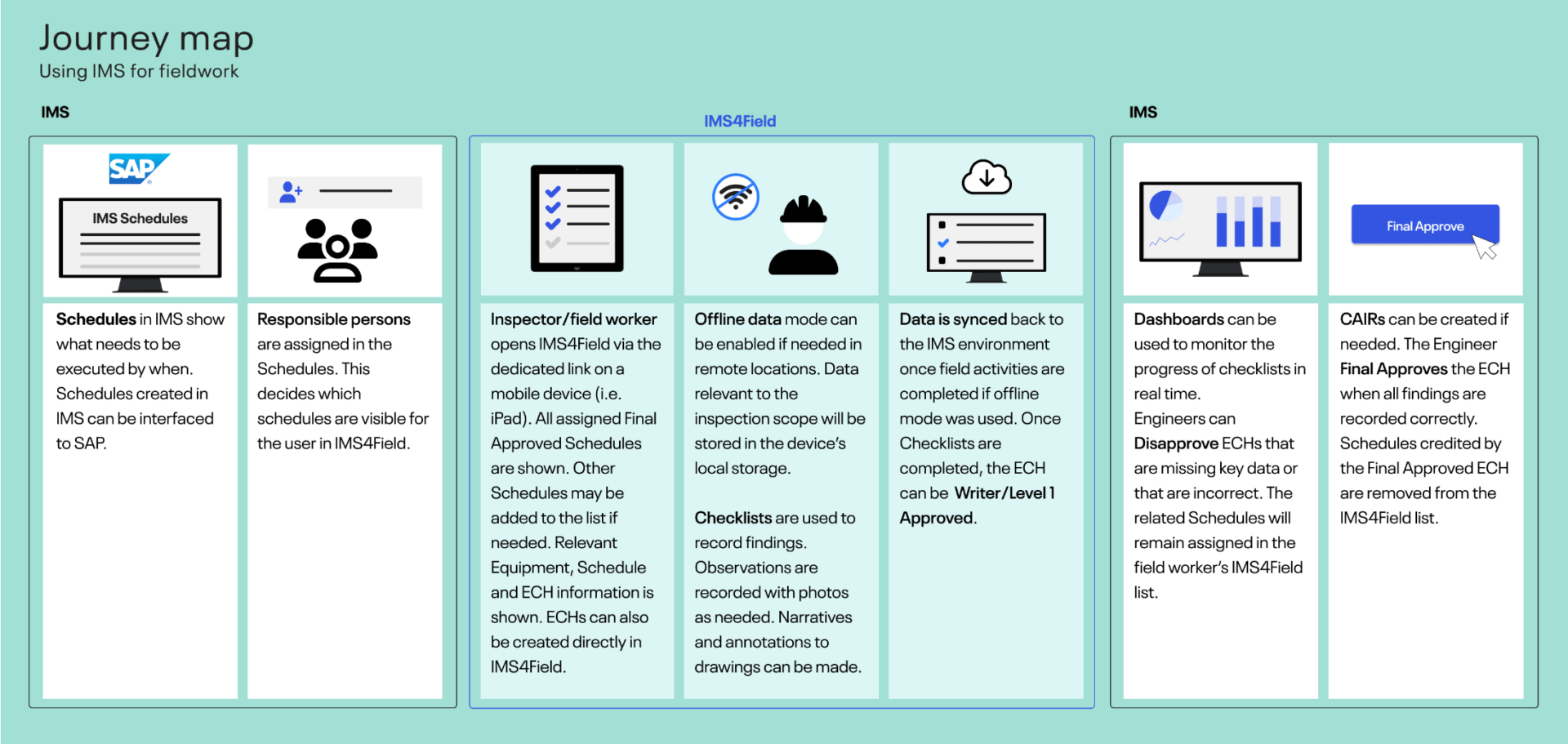

Below you can see how you can incorporate IMS4Field into your fieldwork journey. IMS4Field displays only the schedules that require the fieldworkers’ attention, avoiding distractions. Its user-friendly mobile interface guides them through all the relevant information and tasks for their inspections or other fieldwork, keeping them on track.

For more information on IMS4Field see: The IMS Handbook.

For existing customers, contact your Account manager to onboard the new product.

Not a customer yet? Click here to request a demo.

Improved 3D capabilities

In IMS, you can now pick an item in the FLOC/Equipment main screen grid, and voila, the 3D model for that item pops up in a second browser tab showing the 3D dashboard.

We also made several improvements to our AIR3D module. “What is AIR3D?” I hear you ask. Well, with AIR3D you can import images and point clouds into IMS, spot integrity issues using machine vision and the AIR algorithm, map observations to 3D models and equipment, and then review the remote inspection findings in IMS.

In this update, we’ve enhanced point cloud import by allowing the merging of point clouds during import. We’ve also fine-tuned machine vision by introducing image slicing, handy for handling large photos (think drone-captured images). Plus, we’ve leveled up our mapping intelligence to auto-select a piping system for 3D mapped observations, simplifying the process of creating a CAIR for that Equipment.

For more information on the 3D dashboard see: The IMS Handbook.

Dynamic Form Improvements

We have yet again improved Dynamic Form export functionality. In the last release we already added the Excel export and import functionality with our handy import wizard. Now you can also export checklist data in pivoted format from both the Equipment Condition History (ECH) and Schedules main grid. Data are exported as pivot tables in which Questions/Fields are columns, sorted by sequence. This can be especially useful for data analysis. Also, the exported file can be reimported to update existing data or to import the same data for another object.

P.S. If you’re excited about creating your own Dynamic Forms, take note that we recently launched a Dynamic Forms eLearning course. It covers all the intricacies of Dynamic Forms and will help you become an expert quickly!

For more information on the Dynamic Form export and import see: The IMS Handbook.

For information on the other IMS Platform improvements see: IMS Platform (General) Release 2023.2.

IMS PEI Improvements

The new PEI release brings streamlined tank degradation management, as well as improvements to Schedules and Equipment Condition Histories (ECHs).

Streamlined Tank Degradation Management

We’ve been working hard to streamline the tank degradation management process. We moved tank Risk-Based Inspection (RBI) analysis to the component level, aligning it better with other equipment. We also updated our corrosion loops to account for all tank degradation scenarios. Not stopping there, the use of the main RBI analysis was extended to non-storage tanks, making life more straightforward for everyone. Lastly, we introduced dynamic form checklists designed specifically for tank inspections.

For more information on Tank Degradation Management see: The IMS Handbook.

Scaffolding Option for all Schedule Types

Previously, the scaffolding option was exclusive to CAIR Schedules, but now it’s accessible across the board. All schedule types now have the scaffolding option which can be added from the schedule details page by ticking the checkbox. Importantly, this addition does not necessitate reapproval of the Schedule. This way you can keep much better track of your scaffolding work!

For more information on the Scaffolding option see: The IMS Handbook.

New Dynamic Forms Available in PEI

We’ve introduced a brand-new Dynamic Form Checklist for Schedules. The “Temporary Repair” Dynamic Form Checklist is exclusively accessible for CAIR schedule types, provided that you select the “Is this a Temporary repair?” option. This is one more feature to help you standardize your inspection and maintenance programs.

Furthermore, we’ve transformed the LEAK and LEAK SAVE Checklists into Dynamic Forms, enhancing the intelligence and efficiency of LEAK and LEAK SAVE data collection.

For more information on marking CAIRs for temporary repairs see: IMS Handbook.

For more information on using Dynamic Forms see: IMS Handbook.

For information on the other IMS PEI improvements see: PEI Release 2023.2.

IMS SIS Improvements

IMS SIS capabilities continued to advance in this Release, with the most significant enhancement being the introduction of Bowtie visualization for HAZOPs and LOPAs.

Bowtie Visualization

It is now possible to generate a Bowtie diagram from a consequence identified during a HAZOP analysis. This Bowtie effectively represents both HAZOP and LOPA data. Bowtie analysis is a powerful, visual risk management tool used to pinpoint, assess, and control high-risk accident scenarios. It offers a comprehensive view of these accident scenarios and the protective measures in place to prevent or mitigate their consequences. When applied to a specific hazard, the Bowtie method aids in managing both accident risks and the associated barriers by identifying the most critical ones.

For more information on the new Bowtie feature see: The IMS Handbook.

For information on the other IMS PLSS improvements see: SIS Release 2023.2.

IMS FCM Improvements

For FCM we made some very impactful improvements with regards to the workflow.

New Improved Flange Management Work Process

This release saw a fresh FCM workflow to provide FCM users access to advanced tools in IMS. This update also aims to align workflows with other IMS modules.

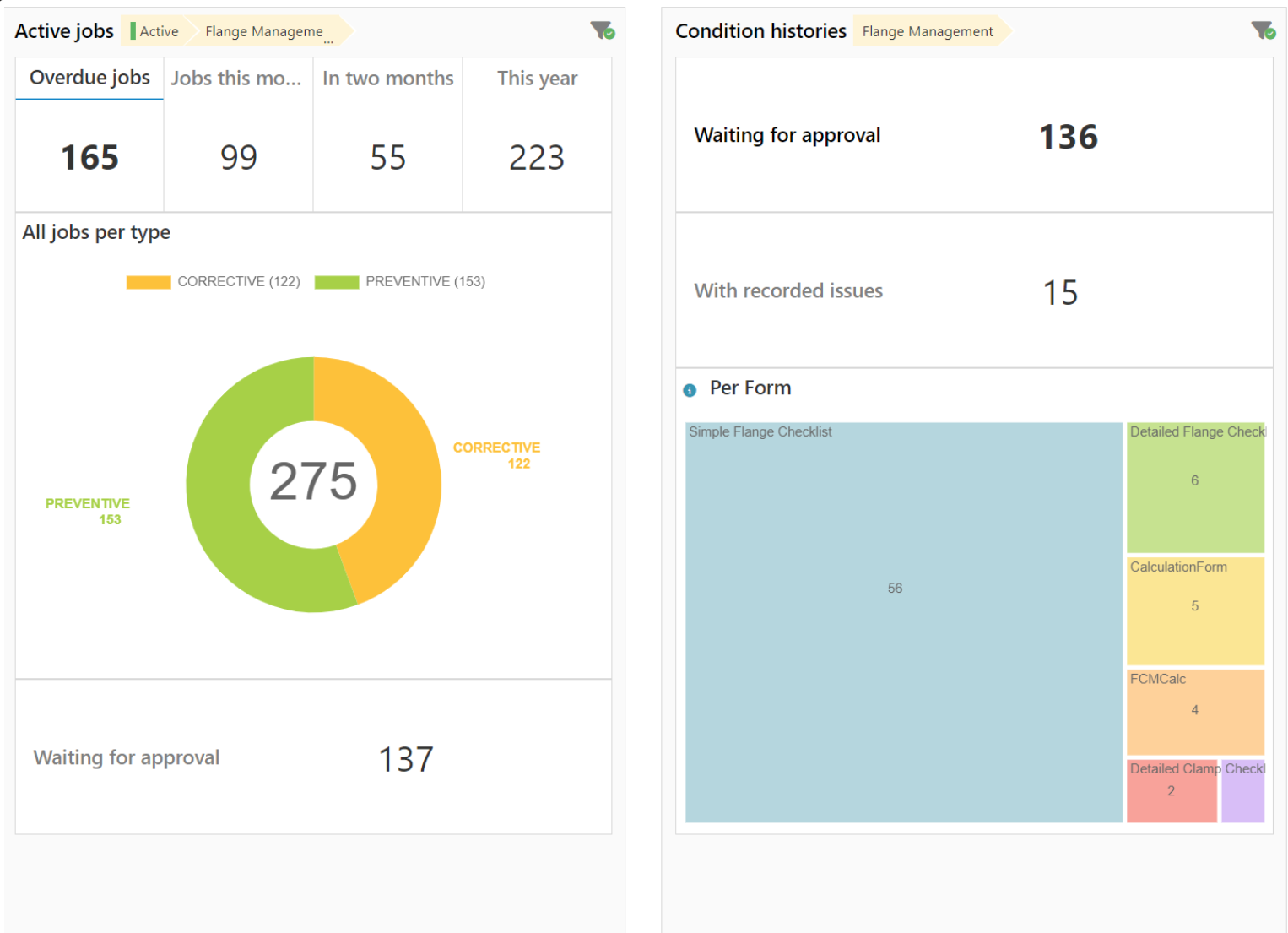

Noteworthy changes include a revised approach to creating Jobs and ECHs. Now, FCM users can create jobs encompassing both Flanges and Graylocs. Additionally, we incorporated a new grid into the job details page, listing the FLOCs of the equipment connected to those Flanges or Graylocs. We introduced new dashboards tailored to the revamped FCM workflow. To top it off, we’ve developed new dynamic form checklists for both Flanges and Graylocs, covering both simple and full protocols.

For more information on the new FCM workflow see: The IMS Handbook.

For information on the other IMS PLSS improvements see: FCM Release 2023.2.

IMS RCM Improvements

RCM has seen multiple usability improvements with this release.

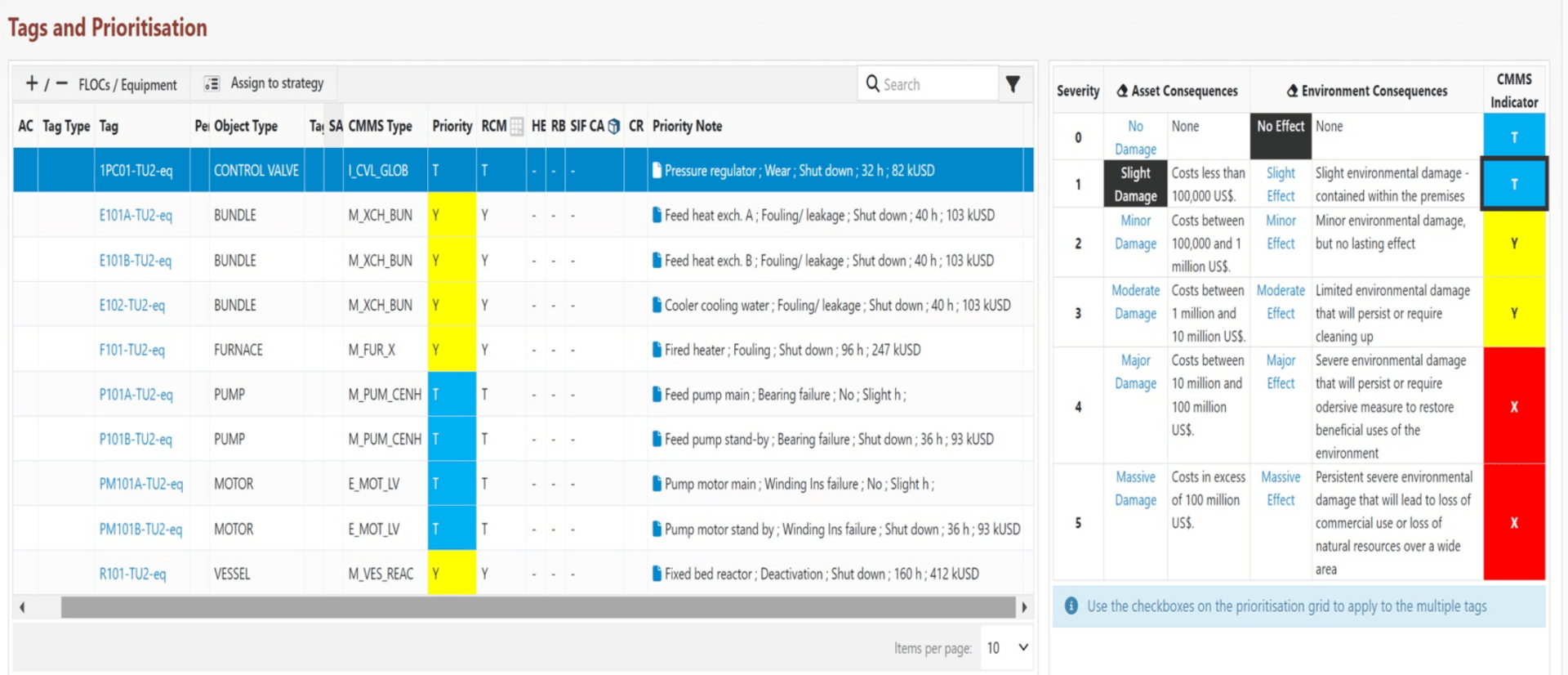

System Tags and Prioritization Enhancements

We’ve added some handy features to the “Tags and Prioritization” grid on the systems details page. Now, you can collapse the priority matrix to see all the tag grid columns with the new prioritization button. We’ve also introduced two new columns for detailed priority data (“Asset Consequences” and “Environment Consequences”) that you can edit directly in the grid. To make things even smoother, we’ve included import and export buttons for convenient bulk handling of priority data.

For more information on the system “Tags and Prioritization” grid see: The IMS Handbook.

What If Scenario Enhancements

“What If Scenarios” for RCM analyses can be used to assess alternatives and show the thinking behind decisions, for this reason it can be of value to export, especially when an RCM analysis “expires” into a new revision. As a response to this need, we introduced multiple export options for “What If Scenarios” in IMS. Furthermore, you can now import “What If Scenarios” using the import wizard. Additionally, “What If Scenarios” are no longer presented as “sub-rows” but instead as a dedicated view.

For more information on What-if analyses see: The IMS Handbook.

Dynamic MEI in copied Analysis

We’ve made Maintenance Efficiency Index (MEI) calculations smarter by using the right Production Loss Equation (PLE). When an RCM analysis is copied from one tag to another, an option to replace the failure mode and task PLE with the PLE of the target System is offered. If checked, the MEI is calculated based on the PLE of the target System. If the option is left unchecked, the PLE from the original tag is used.

For more information on copying analyses see: The IMS Handbook.

For information on the other IMS RCM improvements see: RCM Release 2023.2.

IMS PLSS Improvements

PLSS development focused on usability improvements, especially with regards to Fit For Service (FFS).

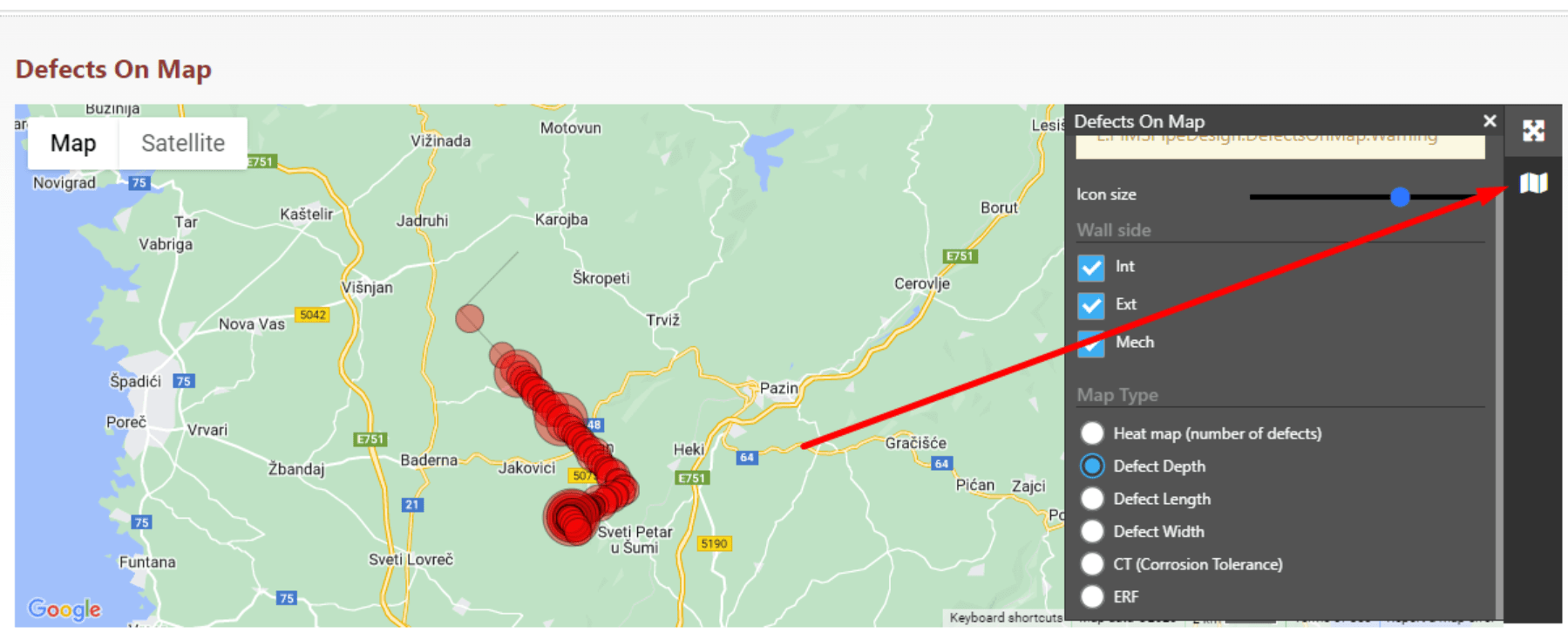

More Transparent FFS View

We’ve introduced a new section on the Fit For Service (FFS) details page called “Defects on Map”. This section lets you visualize the locations of defects on the equipment for the listed inspection date found in the “Inspection details and Defects” section under the assessment tab. To access this feature, simply click on one of the entries in the assessment tab.

For more information on the Defects on Map section see: The IMS Handbook.

Improved Campaign Import

Lastly, we’ve given a makeover to our campaign import and export format. Now, you can easily connect existing anomalies or even create new ones right within the campaigns workpack export/import file. Also, you can import attachments all in one go with a single import. It’s a real time-saver!

For more information on see: The IMS Handbook.

For information on the other IMS PLSS improvements see: PLSS Release 2023.2.

Elsa Tolsma-de Klerk Technical Writer

Elsa is an engineer who enjoys bringing people together through knowledge. She has a Master’s in Electronic Engineering and spent over 10 years at Sasol, a global petrochemical company. There, she began her career as an Advanced Process Control Engineer, gaining hands-on experience in process optimization and control systems, while also discovering a talent for writing detailed operating philosophies. Since 2019, she’s brought that mix of engineering know-how and writing skills to her role as a Technical Writer at Cenosco, and now leads the team that looks after the IMS knowledge base and training Academy.