In this blog post based on our webinar, How to Implement and have effective technical barrier management in your pipelines, we will guide you through implementing and effectively managing technical safety barriers for your pipelines. We will cover the Integrity Management Workflow, prioritizing inspection and maintenance activities, and practical implementation using a powerful software solution like IMS PLSS (Pipeline and Subsea Systems).

The Integrity Management Workflow:

The Pipeline Integrity Management Workflow is the backbone of effective technical barrier management. It involves a series of steps to identify potential threats, assess their criticality, and implement necessary measures to mitigate risks. The workflow identifies hazards, assesses risks, and implements safety barriers to prevent incidents. This systematic approach ensures that potential threats are addressed before they escalate into significant issues, reducing the likelihood of accidents and thus protecting the integrity of the pipeline. The workflow typically includes the following stages:

a) Hazard Identification: Identifying potential hazards that could compromise the integrity of the pipeline system is one of the key steps to managing the pipeline’s integrity. A pipeline operator must identify all potential hazards that could damage the pipeline over its lifecycle. These hazards can be internal or external, including corrosion, third-party interference, geotechnical issues, etc.

b) Risk Assessment: Evaluating the probability and consequences of each identified hazard to determine the level of risk it poses to the pipeline system. Probability defines the likelihood of failure of a pipeline due to a specific hazard, whereas consequence defines potential damage caused due to the failure of a pipeline.

c) Barrier Identification: Once the hazard is identified and the associated risk is understood, the next step involved is to identify barriers that could potentially reduce the likelihood of failure and/or consequence of failure. Barriers can be physical (e.g., corrosion-resistant coatings), operational (e.g., regular inspections), or organizational (e.g., training programs).

d) Barrier Monitoring: This step involves identifying essential inspection and maintenance activities to continuously monitor the performance of barriers to ensure they remain effective in preventing or mitigating potential hazards.

Prioritizing Inspection and Maintenance Activities:

It is crucial to prioritize inspection and maintenance activities to ensure efficient technical barrier management. Prioritizing inspection and maintenance activities further strengthens technical barrier management. Regular inspections, maintenance, and monitoring allow operators to detect early signs of degradation or weaknesses in the pipeline system and its associated barriers. This allows for timely interventions and remedial efforts to reinforce or replace barriers, ensuring they remain effective over time.

The following steps outline a systematic approach to prioritize these activities:

Inspect & Analyze

Regular inspections and maintenance of the pipeline system help identify potential issues and assess the condition of barriers. This step involves gathering data through inspections, testing, and monitoring.

Indicators:

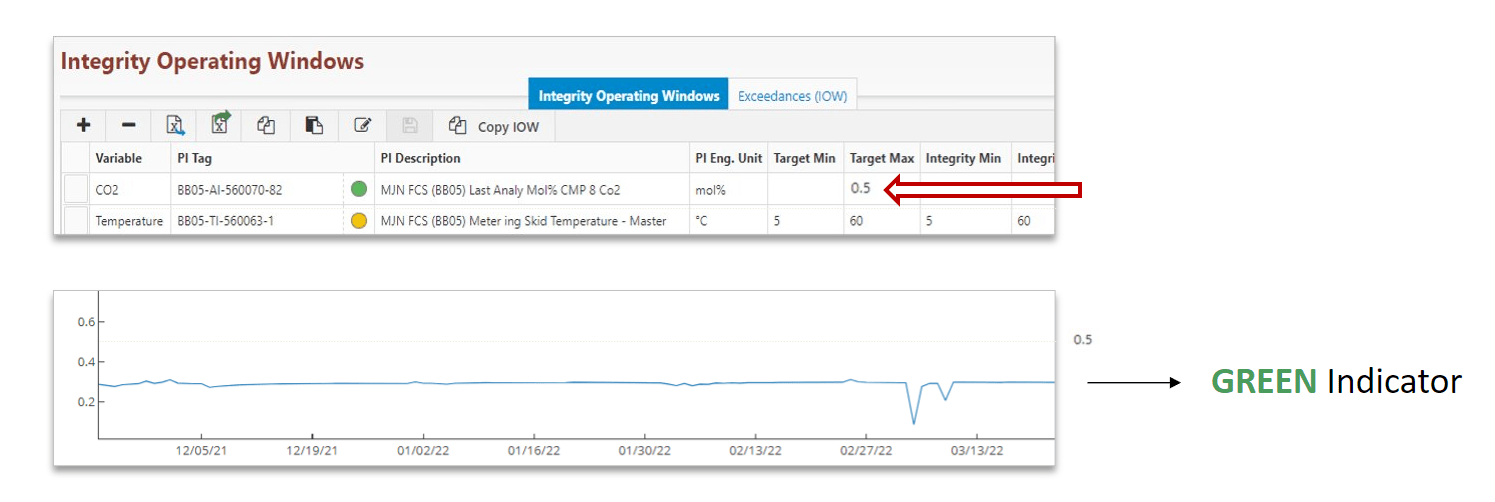

Defining performance indicators for barriers helps quantify their effectiveness. Performance Indicators can be used to measure factors such as corrosion rate, leak frequency, or pressure drops.

Barrier Statuses:

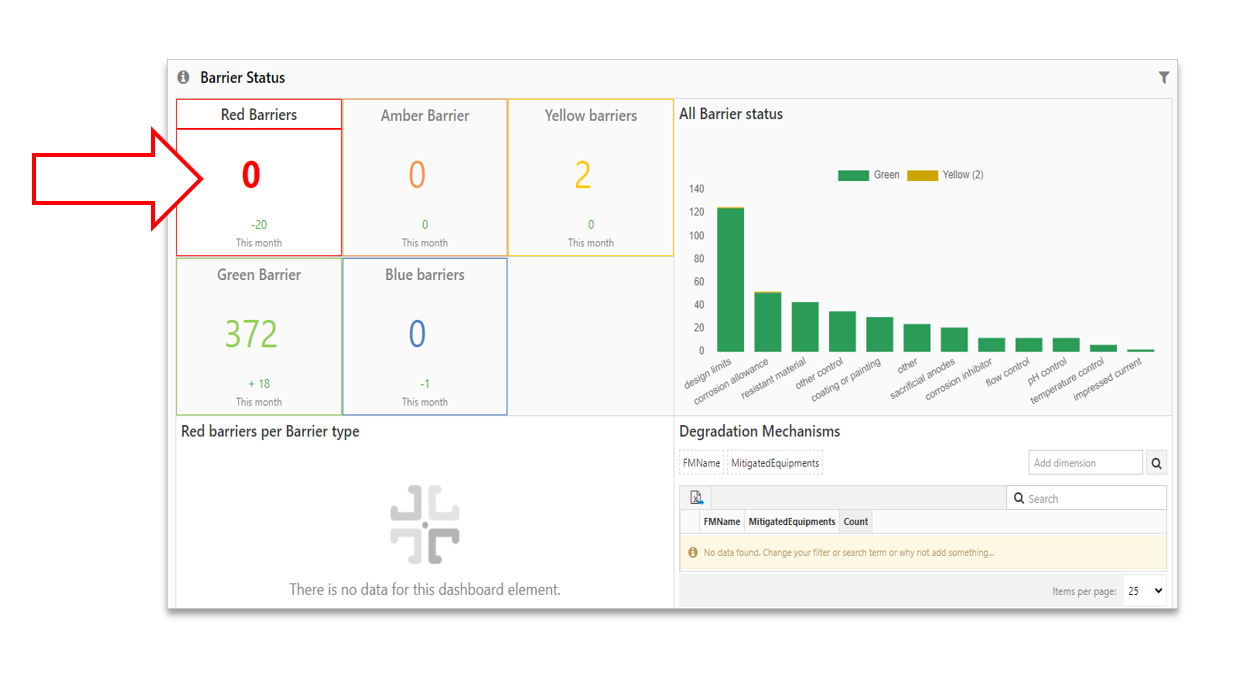

Classifying barriers based on their current status is vital for decision-making. Barriers can be categorized as active, passive, or impaired based on their condition and performance.

Dashboard:

Utilizing a centralized dashboard visualizes barrier statuses and enables better decision-making and resource allocation.

Practical Implementation with IMS PLSS:

IMS PLSS (Pipeline and Subsea Systems) is a cutting-edge software solution streamlining the technical barrier management process. The use of advanced software solutions like IMS PLSS revolutionizes the technical barrier management process. Such software offers sophisticated tools for data analysis, risk assessment, and barrier tracking. Integrating software with SAP facilitates streamlined data exchange and enhances decision-making capabilities. As a result, pipeline operators can make well-informed decisions about allocating resources, optimizing maintenance efforts, and prioritizing improvements in the most critical areas.

It offers various features to enhance the efficiency of TBM implementation:

- Hazard Database: IMS PLSS has a comprehensive hazard database, allowing users to identify and prioritize potential threats more effectively.

- Risk Assessment Module: The software incorporates risk assessment tools that analyze data to determine the severity of identified hazards.

- Barrier Tracking: IMS PLSS enables seamless monitoring of barriers, helping users assess their performance and take necessary actions when needed.

- Integration with SAP: One of the key features of IMS PLSS is its ability to interface with SAP, allowing for seamless data exchange and facilitating better overall pipeline integrity management.

Implementing effective technical barrier management is critical to maintaining the integrity and safety of pipelines. Prioritizing safety and integrity through robust technical barrier management protects the environment and communities and secures the future of the pipeline industry, and has far-reaching implications beyond the immediate protection of pipelines. It protects the environment by reducing the likelihood of leaks or spills that can cause ecological damage and contamination.

Communities living near pipeline infrastructure benefit from reduced risks of accidents, ensuring their safety and well-being. By proactively implementing technical barrier management strategies, the pipeline industry can build trust with stakeholders, investors, and the public, leading to greater acceptance and support for pipeline projects.

In conclusion, a proactive approach to technical barrier management is not just a box to check for pipeline operators; it is a fundamental responsibility that ensures the safe and reliable transportation of resources and protects the environment and communities, safeguards against potential incidents, and strengthens the pipeline industry’s sustainability and resilience in the face of evolving challenges and expectations.

See IMS PLSS in action

Fill out the form below to see what IMS PLSS can do for you!