Safety Instrumented Functions (SIFs) are critical components of a Safety Instrumented System (SIS). They are designed to reduce or mitigate risks in industrial processes. A measure used to assess the reliability of a SIF in achieving its safety function when called upon is the Probability of Failure on Demand (PFD). In calculating the PFD of a SIF, you must take multiple factors into account, including Failure Rates, System Configuration, Diagnostic Coverage, Proof Test Interval, and Test Coverage Factors. In this blog post, we will explore Test Coverage Factors and their importance in calculating PFDs.

What is a Test Coverage Factor?

The test coverage factor reflects the effectiveness of testing and maintenance activities in detecting and preventing failures within the SIF. It quantifies the probability that a diagnostic test will detect a dangerous failure before it affects the SIF’s performance. Test coverage is typically expressed as a percentage, ranging from 0% (no test coverage) to 100% (perfect test coverage).

Car Analogy

Imagine your car’s yearly checkup at the garage. It’s like a routine health check for your vehicle to ensure it’s safe for you and your family. During this inspection, mechanics examine various safety features built into your car, like seatbelts, brakes, lights, oil levels, tires, and indicators. They do this to verify that these safety mechanisms still work as intended, with no hidden issues that could jeopardize your safety while driving.

Now, let’s suppose your car has a total of 10 safety features designed to protect you in case something goes wrong while you’re on the road. During the checkup, the mechanic can test and verify the functionality of 9 of these safety features. However, there’s one safety feature that they can’t assess in the garage.

In this scenario, we can say that the Test Coverage Factor of the yearly checkup, which checks 9 out of 10 safety-related features for any concealed problems, is 90%. This percentage represents how comprehensively the inspection assesses the safety mechanisms in your car, helping ensure your peace of mind while driving.

Understanding Test Coverage Factors is crucial because they reveal how effectively safety checks can identify potential issues in complex systems, such as industrial processes or critical equipment, ultimately contributing to safer operations and peace of mind for everyone involved.

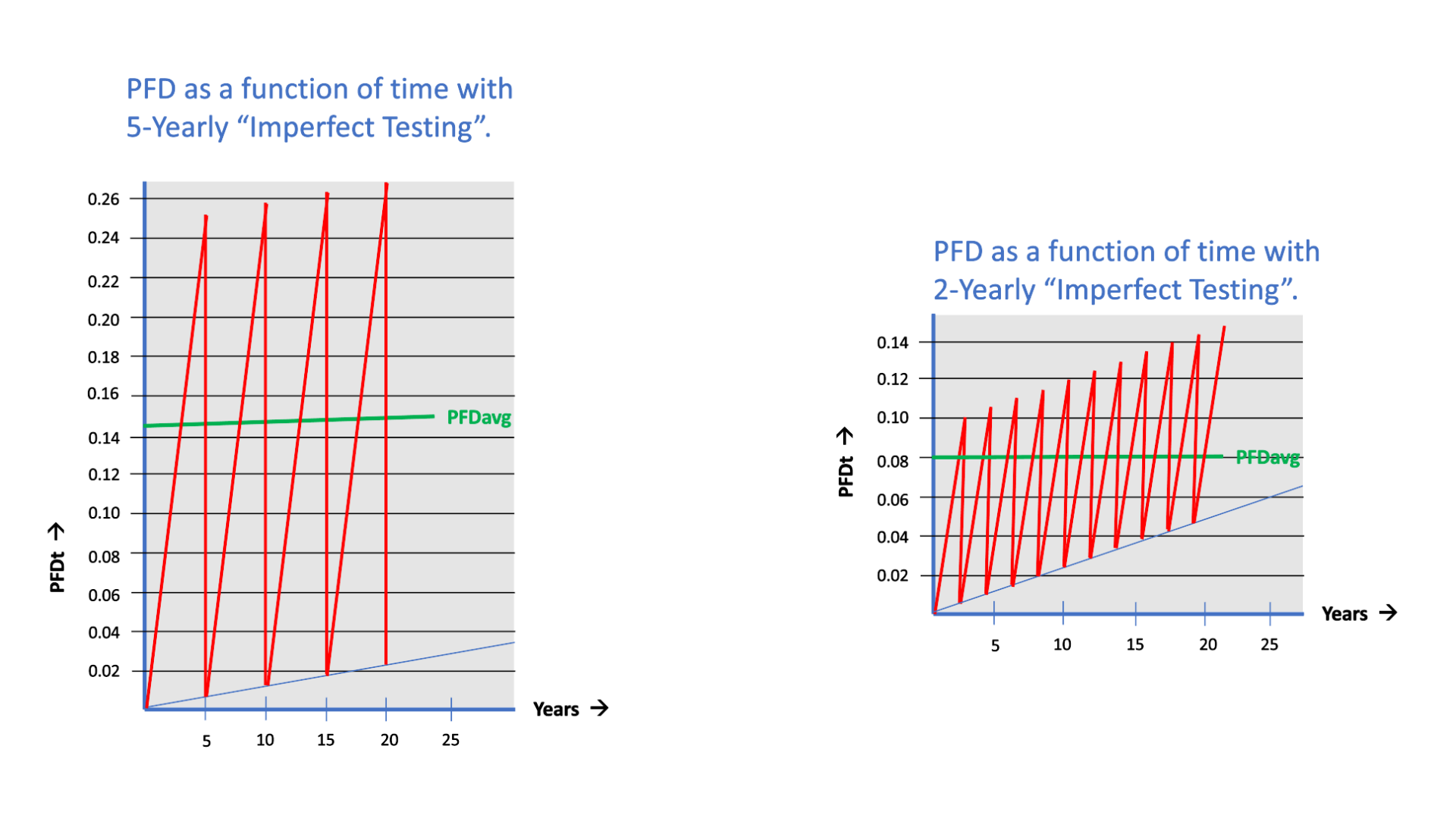

How does a Test Coverage Factor affect SIF PFD Calculations?

When the Test Coverage Factor is high (close to 100%), it means that the diagnostic tests and maintenance procedures are very effective in detecting and preventing dangerous failures. In this case, the PFD of the SIF is reduced because the probability of a dangerous failure going undetected is low. A high Test Coverage Factor leads to a lower PFD, which is desirable for safety.

Conversely, when the test coverage factor is low, it indicates that the diagnostic tests and maintenance procedures are less effective in detecting and preventing dangerous failures. In such situations, the PFD of the SIF will be higher because there is a greater likelihood that a dangerous failure may go undetected. A low Test Coverage Factor leads to a higher PFD, which can be undesirable for safety.

Ready to gain some practical insights into test procedures, FMEA, and SIF Proof Test Coverage?

Download the White Paper

Get insights from our experts in our latest white paper.

Denis Tkalec Technical Writer

Denis Tkalec is a technical writer at Cenosco, specializing in asset integrity management software since 2022. With a background in education and six years in marketing, she turns complex topics into clear, user-friendly content. Inspired by Camus’s belief that “a writer keeps civilization from destroying itself,” she brings precision and care to every manual.