Artificial Intelligence (AI) isn’t just a buzzword; it’s a game-changer.

Imagine a world where machines think, anticipate needs, and solve problems before they arise. Now, consider this power applied to managing assets—the backbone of industries worldwide. That’s where AI meets Asset Integrity Management (AIM), offering a blend of predictive capabilities and strategic insight that promises to redefine how we safeguard and optimize our assets.

Join us as we uncover how AI and Asset Integrity Management (AIM) work together to improve asset management.

To delve into the intricacies of this subject, we tapped into the expertise of Dan Jeavons, the VP of Computational Science & Digital Innovation & IT CTO at Shell. We sat Dan down with Cenosco’s Director of Engineering, Josip Hrvatin, and Solutions Engineer, Luiz Curado, to dig deep into their extensive experience and insights to offer a profound understanding of the transformative journey of AI within asset management.

The conversation delved into the challenges of limited data accessibility hindering widespread AI applications, driving the imperative for digitization. Continue reading to explore the insights brought to light during this conversation, or click here to watch the webinar.

Shell’s Digital Evolution

Shell embarked on its digital transformation journey a decade ago by establishing an Advanced Analytics Centre of Excellence. Today, Shell boasts over a hundred AI applications in production, with a formidable team of over 600 data scientists and more than 12000 Members in its Shell.AI Network.

Through this, Shell stands at the forefront of harnessing AI’s potential to optimize operations, partnering with various companies, including Cenosco.

The exponential growth in data volumes and computational capabilities due to digitalization has revolutionized what is achievable, fueling this surge in innovation. As data becomes more abundant and processing power continues to improve, Shell has seized the opportunity to extract actionable insights from this wealth of information.

These insights, powered by AI algorithms, have proven instrumental in enhancing decision-making processes, predicting maintenance needs, and optimizing asset performance.

Navigating Digital Transformation with Cenosco’s Framework

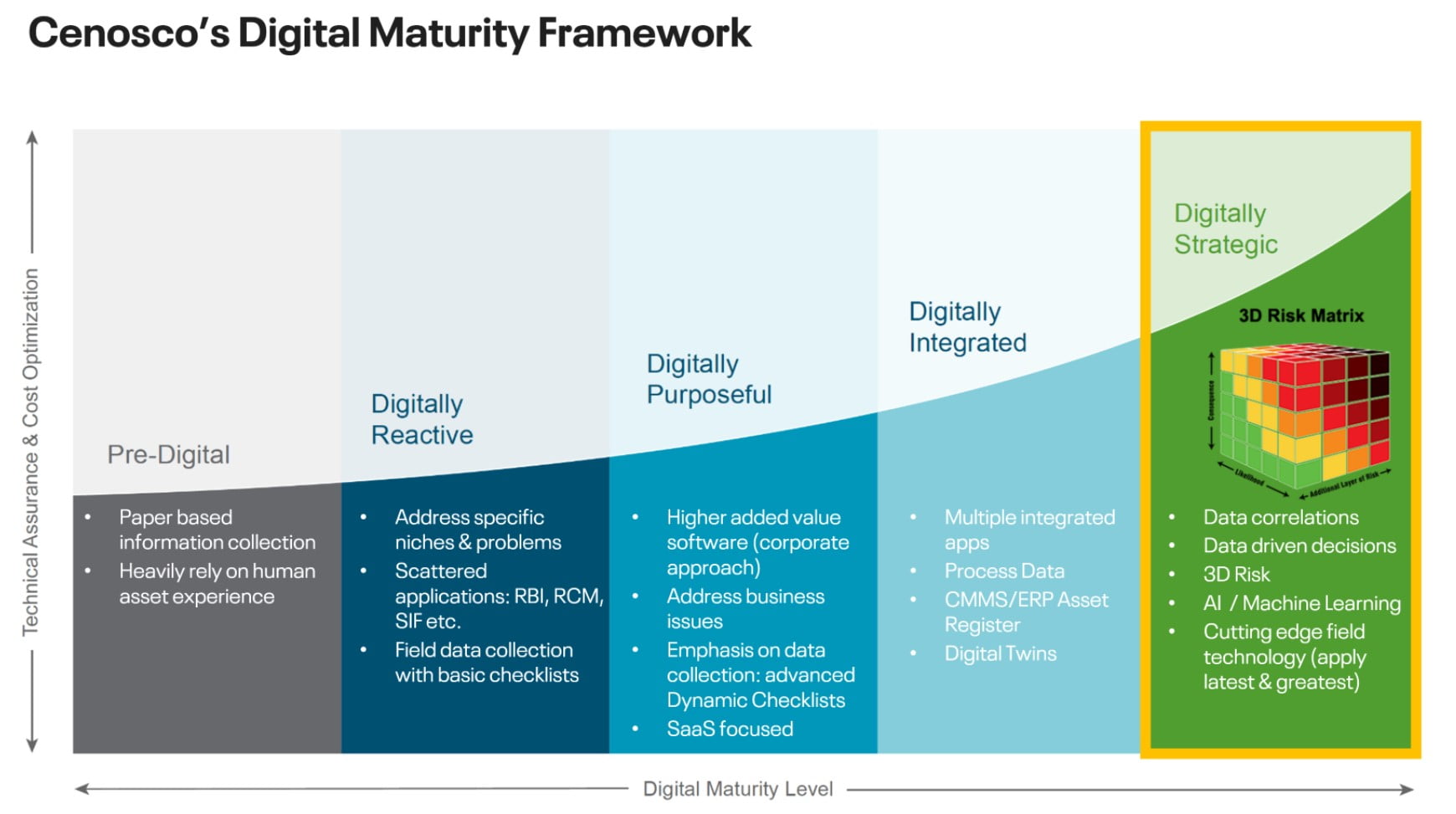

Cenosco’s Digital Maturity Framework is a guiding framework for organizations navigating digital transformation journeys. Advancing through this maturity model is a gradual journey that necessitates strategic planning and integration.

Organizations aspiring to reach the “Digital Strategic” phase must recognize the importance of integrated solutions, leveraging data and AI to drive innovation effectively. Request a demo to learn more about this framework.

When working with AI or any other emerging technology, thinking about being digitally purposeful is crucial.

What this means is that you must have purpose and goals aligned with your pursuit, as digital tools enable innovation rather than being ends in themselves. Getting the technology is only one part of the journey. Integrating AI into asset management becomes crucial as we aim to make assets safer and more reliable.

However, this integration does not entail a complete overhaul of existing processes; rather, it involves adapting and enhancing current practices to harness the potential of AI effectively. While AI will not replace inspectors or corrosion engineers in the foreseeable future, it can augment their capabilities by offering valuable insights derived from extensive datasets and predictive analytics.

Aligning digital expertise with a deep understanding of robust work processes is paramount. Technology will not replace the processes we work with but rather change the way we carry them out.

Learn more about this in our webinar, where Dan Jeavons shares an example from Shell, where the utilization of AI for proactive technical monitoring and optimization has yielded tangible benefits, ranging from averting reliability issues to optimizing production and reducing emissions.

“It’s not just about implementing the technology, it’s also about embedding it in transformed worked processes. “

Dan Jeavons

VP of Computational Science & Digital Innovation & IT CTO at Shell

The Open AI Energy Initiative

The Open AI Energy Initiative is a collaborative endeavor led by Shell and other industry leaders, such as Microsoft, Baker Hughes, and Cenosco. It utilizes AI solutions for energy sector challenges.

This strategic initiative aims to revolutionize operations by seamlessly integrating digital technologies and prioritizing open data standards and interoperability to foster innovation. The emphasis lies in breaking down data silos, highlighting the accessibility and collaborative potential of open-source software.

Cenosco has been actively involved in three significant projects within the Open AI Energy Initiative. One of these projects, AIR (Autonomous Integrity Recognition), utilizes drones for remote inspections. These drones capture images, which are then analyzed by AI and machine learning algorithms to identify integrity issues.

The insights gleaned from these analyses are seamlessly integrated into Cenosco’s IMS platform through point clouds and 3D models.

Another initiative, CARMA (Corrosion Advanced Risk Modelling and Analytics), focuses on predicting corrosion rates for various degradation mechanisms. Leveraging data from IMS, an AI system correlates wall thickness measurements and renewal thickness with process conditions to forecast corrosion rates accurately.

The third project is a synthesis of key components from previous endeavors—AIR, corrosion calculation data, and field inspections—to forecast the likelihood of CUI (Corrosion Under Insulation). This amalgamation promises a comprehensive approach to addressing corrosion-related challenges within the energy sector.

These projects underscore the importance of defining clear use cases and adapting solutions to meet evolving needs.

These projects serve as stepping stones toward a future where AI-powered assistants, often called “virtual corrosion engineers,” play a pivotal role in revolutionizing industrial operations. The vision is to integrate AI, data insights, NLP (natural language processing), and physics-based models to enable real-time decision-making.

Envisioning the Future of AI

In exploring the future of AI within the IMS Suite, optimism is evident, particularly with another initiative at Cenosco focusing on integrating artificial intelligence expertise into the company.

Cenosco’s collaboration with the Croatian University of Pula has generated numerous potential applications, such as leak prediction, automated scheduling, voice-command report generation, and more. The most promising AI concepts will be chosen for implementation, driving innovation within Cenosco.

In exploring AI’s potential in data cleaning, our experts emphasized its ability to handle legacy data and optimize processes like ticketing systems. Anticipation is high for AI-powered tools to efficiently sift through historical data, thereby enhancing summarization and overall efficiency.

A similar vision regarding AI’s evolution beyond predictive maintenance to revolutionize data management is echoed. The significance of structured data in integrity management is highlighted, alongside AI’s capacity to extract, summarize, and organize unstructured information effectively. This transformation promises to unlock valuable insights from historical data, significantly impacting safety and reliability.

Despite challenges, there is excitement and anticipation about the prospect of AI-driven data management, which could mark a transformative era in asset management processes.

Data will continue to play a pivotal role in shaping the future of asset management. With the abundance of sensors across assets, processes are bound to evolve, leveraging artificial intelligence to streamline inspections and enhance efficiency. However, this does not signal the end of inspectors; rather, it calls for a shift in their roles towards utilizing AI as a valuable tool.

We stand at the cusp of a transformative era in which technology challenges existing paradigms and necessitates collaboration between companies and individuals. Embracing this change collectively is key to unlocking AI’s full potential and achieving our desired outcomes.

If you’d like to learn more about AI in asset integrity management, check out the full webinar. Our expert speakers discuss these topics in more detail.

Watch Now

Fill out the form below to get instant access to the session with our experts.

Introducing the Experts

Dan Jeavons VP Computational Science & Digital Innovation & IT CTO, Shell

Dan Jeavons, a prominent professional in Shell’s digitalization department, has been instrumental in shaping Shell’s digitalization program. He played a pivotal role in developing the externally recognized Shell.ai brand, and his team’s impactful work has garnered regular attention in prestigious publications like Forbes, the Wall Street Journal, and the Financial Times.

Luiz Curado Solution Engineer & Business Development Manager

Senior mechanical engineer and MBA with over 20 years of international experience in the field of mechanical integrity, inspection, testing and maintenance, who now helps companies with high-risk assets to manage and optimize their maintenance, inspection and test programs with cutting-edge technology.

Josip Pepi Hrvatin Director of Engineering at Cenosco

Josip Hrvatin, as the Director of Engineering at Cenosco, boasts over twenty years of invaluable expertise, driving innovation and technical excellence. His leadership has been pivotal in shaping Cenosco’s engineering initiatives, contributing to continuous advancements in the field. Josip’s dedication to technological excellence positions him as a key figure in Cenosco’s commitment to industry innovation and leadership.

Elsa Tolsma-de Klerk Technical Writer

Elsa is an engineer with a passion for sharing knowledge. She holds a Master’s in Electronic Engineering and spent over a decade at Sasol as an Advanced Process Control Engineer, where she gained hands-on experience in optimization, control systems, and writing technical documentation. Since 2019, she’s been a Technical Writer at Cenosco, now leading the IMS knowledge base and training Academy team.